Method for forming torsion roller

A roll and torsion sleeve technology, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of increasing manufacturing costs, and achieve the effects of prolonging service life, small aspect ratio, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

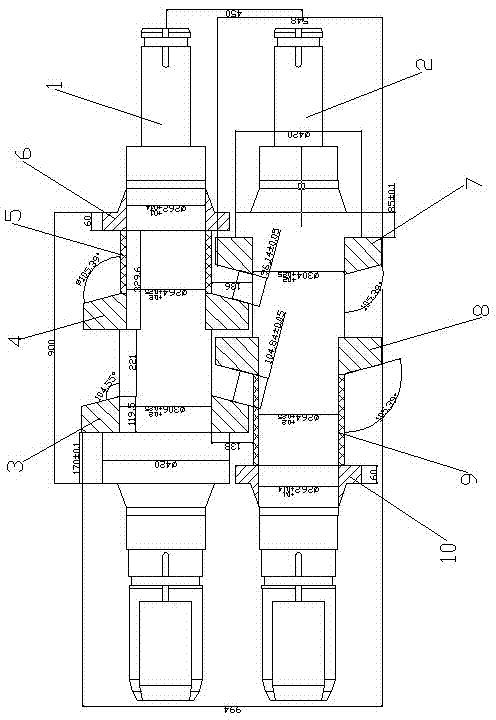

Image

Examples

Embodiment 1

[0026] The production line of the two-roller horizontal rolling mill of the Taiyuan Iron and Steel Stainless Steel Factory is transformed, and the discarded high-line rolls are transformed into twisted rolls by using the method of the invention. The forming method of the twisted roll is:

[0027] 1. Process the scrapped high-line roll into a ladder shape;

[0028] The inner diameter of the upper and lower rolls is 420mm, and two stepped holes are processed on the upper roll, the diameter of the first stepped hole is 306mm, and the diameter of the second stepped hole is 264mm; The hole diameter is 304mm, and the hole diameter of the second stepped hole is 264mm.

[0029] 2. According to the angle of torsion inclination, the torsion sleeve of wear-resistant material is made, and the interference fit is embedded on the roll.

[0030] Use wear-resistant material tool steel to process the torsion sleeve; spacer sleeve and labyrinth ring can be made of ordinary steel. ℃, interfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com