Preparation of magnesia crystal whisker

A technology of magnesium oxide whiskers and magnesium carbonate whiskers, which is applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problems of restricting industrial production and application, unfavorable large-scale production methods, and high equipment requirements. Achieve the effect of promoting high-efficiency comprehensive utilization, low production cost, and good crystal development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

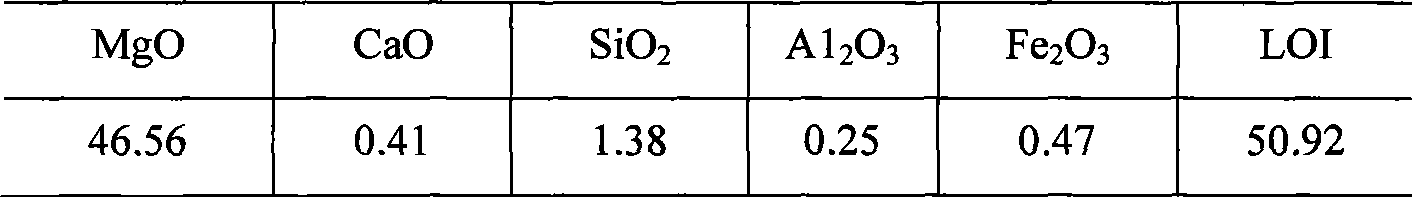

[0029] The discarded magnesite powder ore (particle size range: 0.001-40 mm) was used in Dashiqiao, Liaoning, and its chemical composition is shown in Table 1.

[0030] Table 1 Physical and chemical indicators of magnesite powder ore for implementation (%)

[0031]

[0032] ①Calcination. The magnesite raw material is calcined in a reverberatory furnace at 850°C for 2 hours and lightly calcined to obtain lightly calcined magnesia.

[0033] ② cooling. The lightly burned minerals are naturally cooled to 100°C in the air.

[0034] ③ Hydration. After the cooled light-burned magnesia is crushed in a crusher, it is added to room temperature water 8 times the volume of the mineral, mixed, and finely ground in a ball mill to below 200 mesh.

[0035] ④ Carbonization. ③The slurry after ball milling is diluted with clear water in the water tank, so that the mass ratio of the diluted mineral water is 50kg / 1000L water. While stirring, blow CO into the slurry at a flow rate of 40L / m...

Embodiment 2

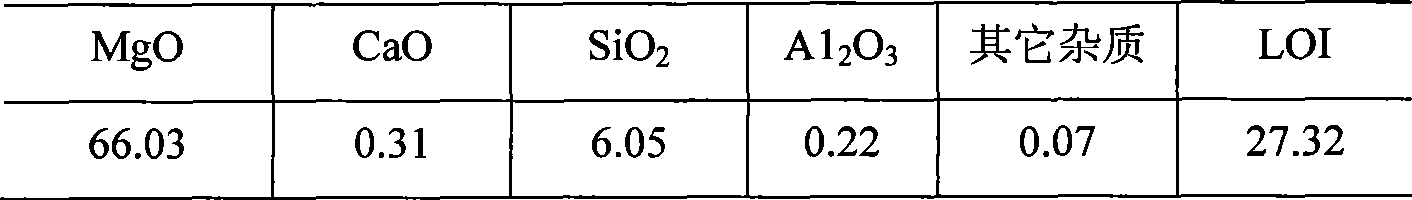

[0042] Liaoning Dandong brucite was used as raw material, and its chemical composition is shown in Table 2.

[0043] Table 2 Implementation of physical and chemical indicators of brucite (%)

[0044]

[0045] ①Calcination. The magnesite raw material is calcined in a reverberatory furnace at 550°C for 2 hours and lightly calcined to obtain lightly calcined magnesia.

[0046] ② cooling. The lightly burned minerals are naturally cooled to 100°C in the air.

[0047] ③ Hydration. After the cooled light-burned magnesia is crushed in a crusher, it is mixed with room temperature water 8 times the volume of the mineral, and finely ground in a ball mill to below 200 mesh.

[0048] ④ Carbonization. (3) The ball-milled slurry is further diluted with water in a water tank, so that the mass ratio of the diluted mineral water is 50kg / 1000L water. While stirring, blow CO into the water slurry at a flow rate of 45L / min (relative to 1000L solution). 2 Gas for 8 hours to make magnesium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com