Deep hole machining manipulator

A manipulator and deep hole technology, which is applied in the field of hole processing, can solve the problems of easy vibration, ripple and taper, large depth-to-diameter ratio, high processing accuracy and surface quality requirements, to ensure processing accuracy and surface quality, and reduce tool size. The effect of high aspect ratio and high tool strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

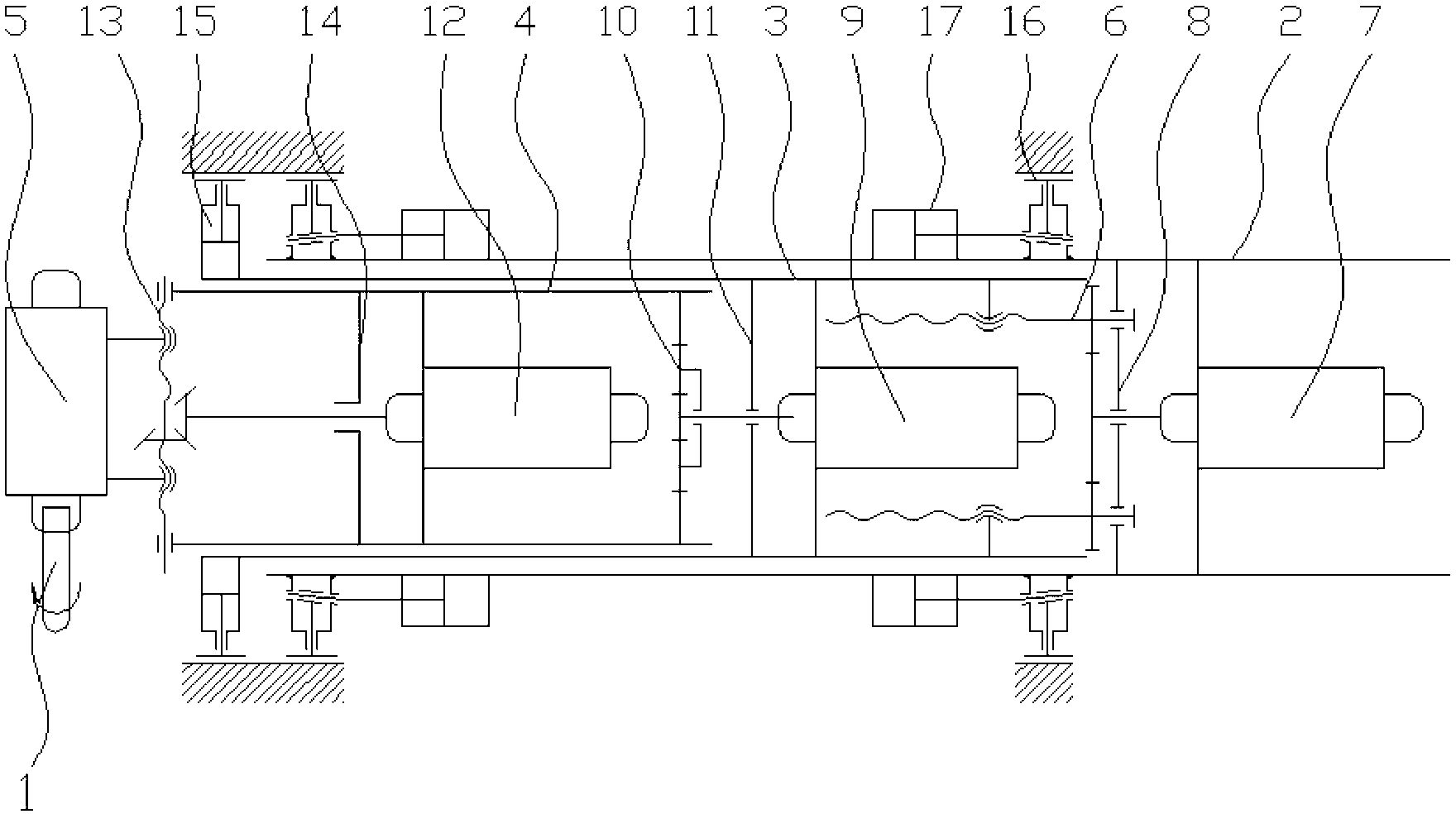

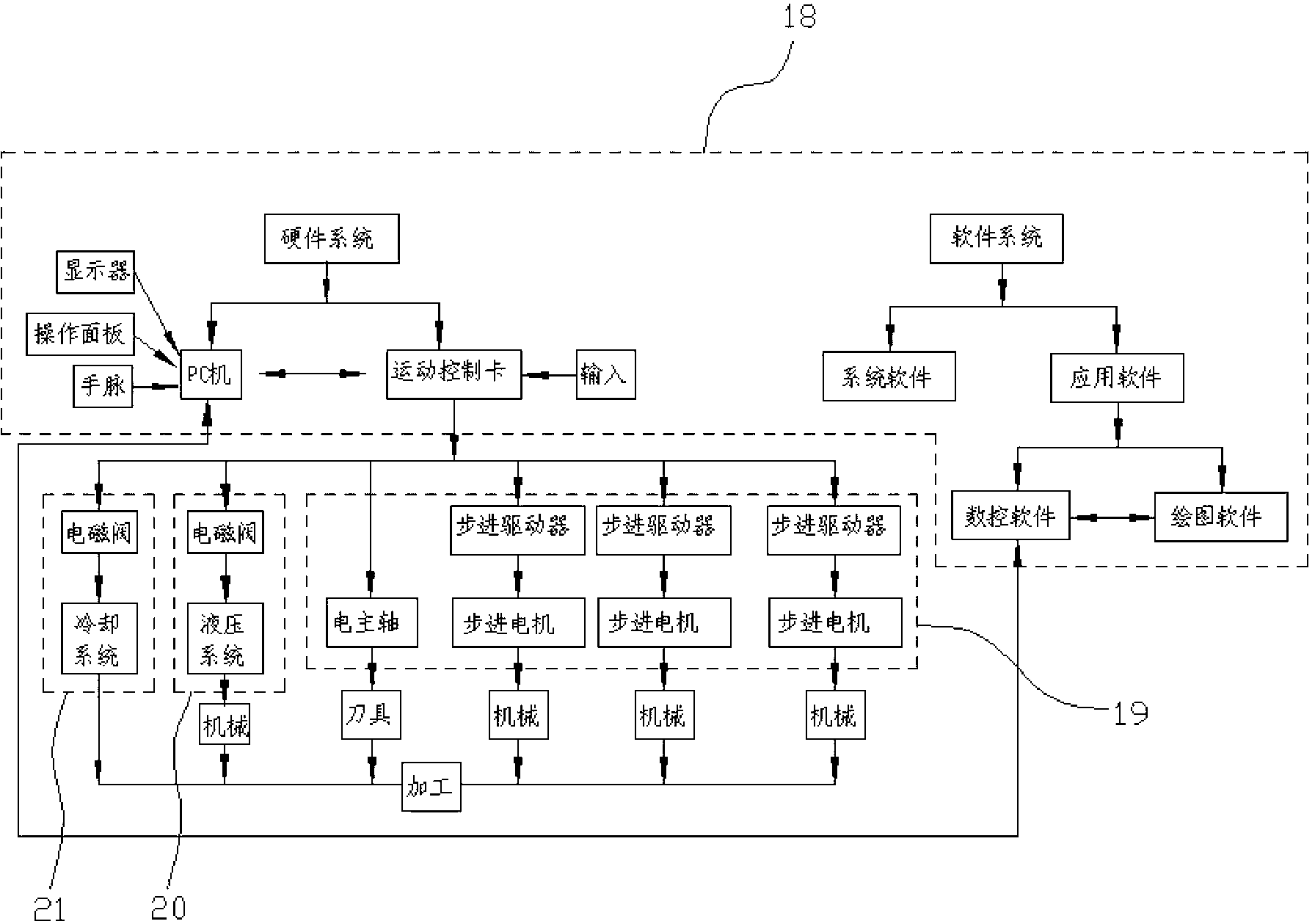

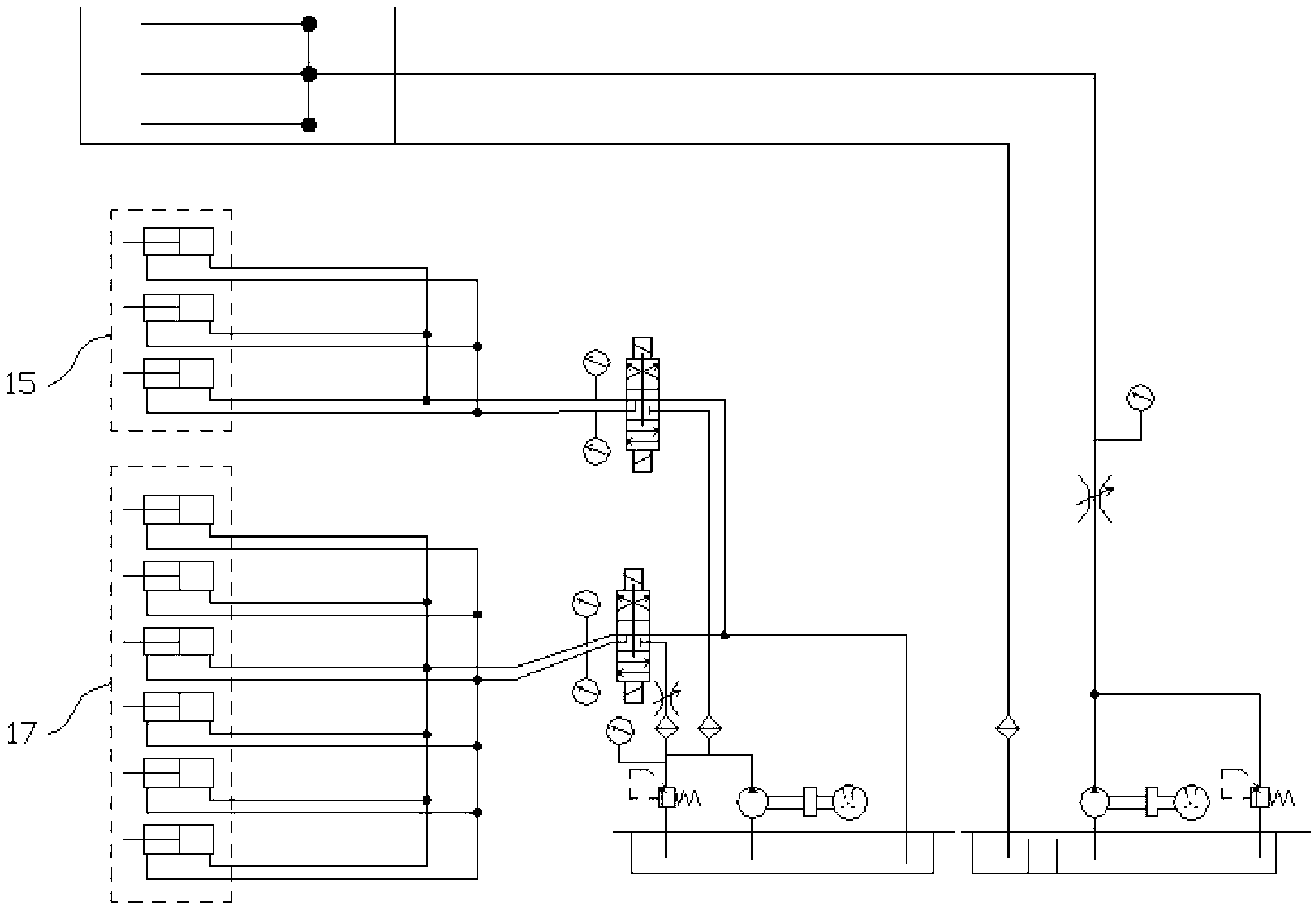

[0021] figure 1 It is the mechanical schematic diagram of the present invention, figure 2 It is a block diagram of the control system of the present invention, image 3 It is the hydraulic principle diagram of the present invention, as shown in the figure: the deep hole processing manipulator of this embodiment includes at least an arm assembly that can provide axial feed and circumferential feed, and a machine tool that is fixed at the output end of the arm assembly. The working device 1 for processing or detection and the control system for controlling the feeding direction of the arm assembly and the working state of the working device 1; the arm assembly includes a fixed arm 2, which is slidably connected to the fixed arm 2 with an axial single degree of freedom The telescopic arm 3, the rotary arm 4 connected to the telescopic arm 3 with a single degree of freedom in the circumferential direction, the fixed seat 5 for fixing the working device 1 installed and positioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com