Arc-shaped thin-walled part outer surface grinding machine tool

A thin-walled, outer surface technology, applied in the direction of grinding machines, grinding workpiece supports, grinding/polishing equipment, etc., can solve the problems affecting the quality of workpieces and deformation of curved parts, and achieve strong fit, avoid deformation, The effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

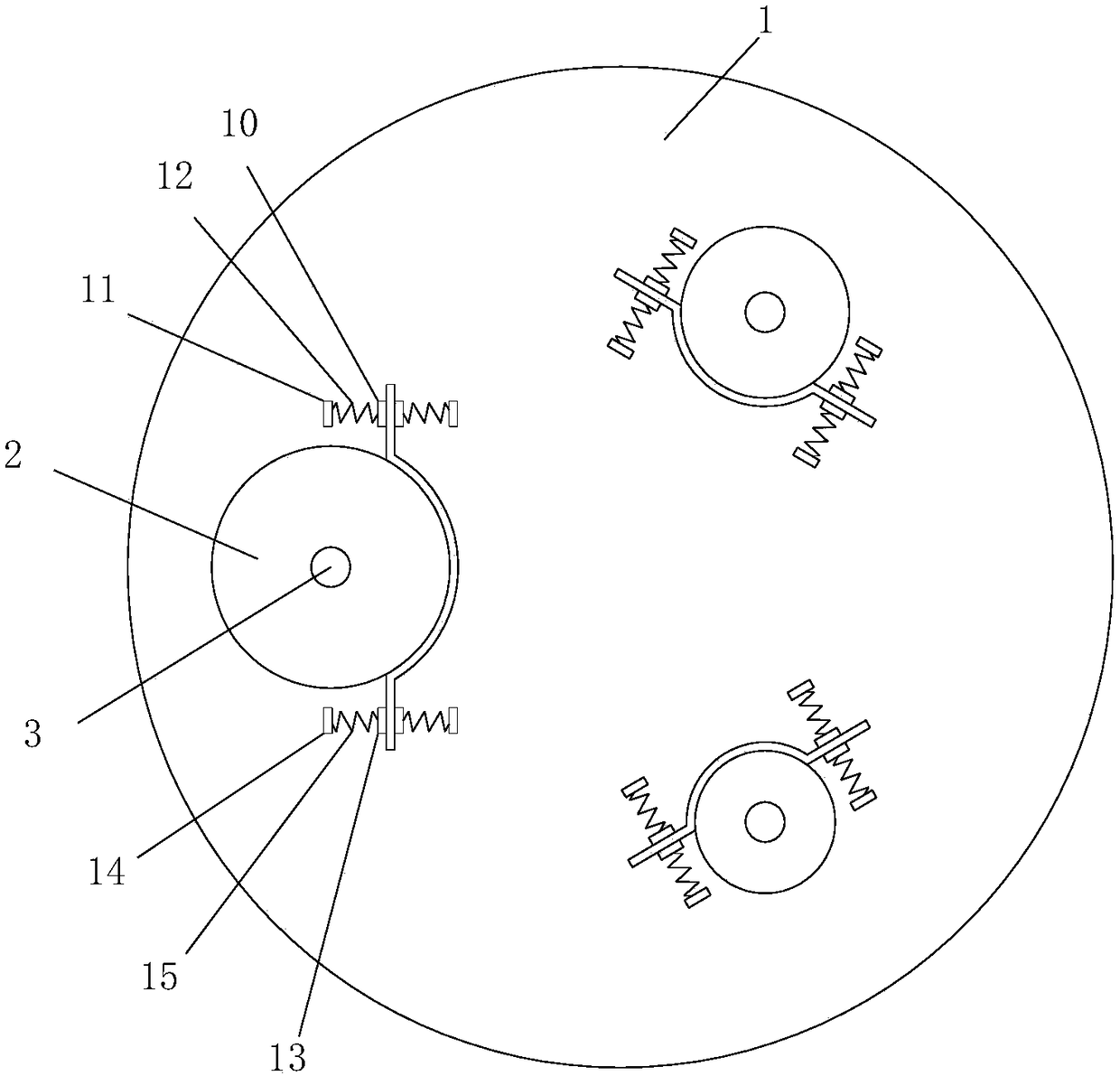

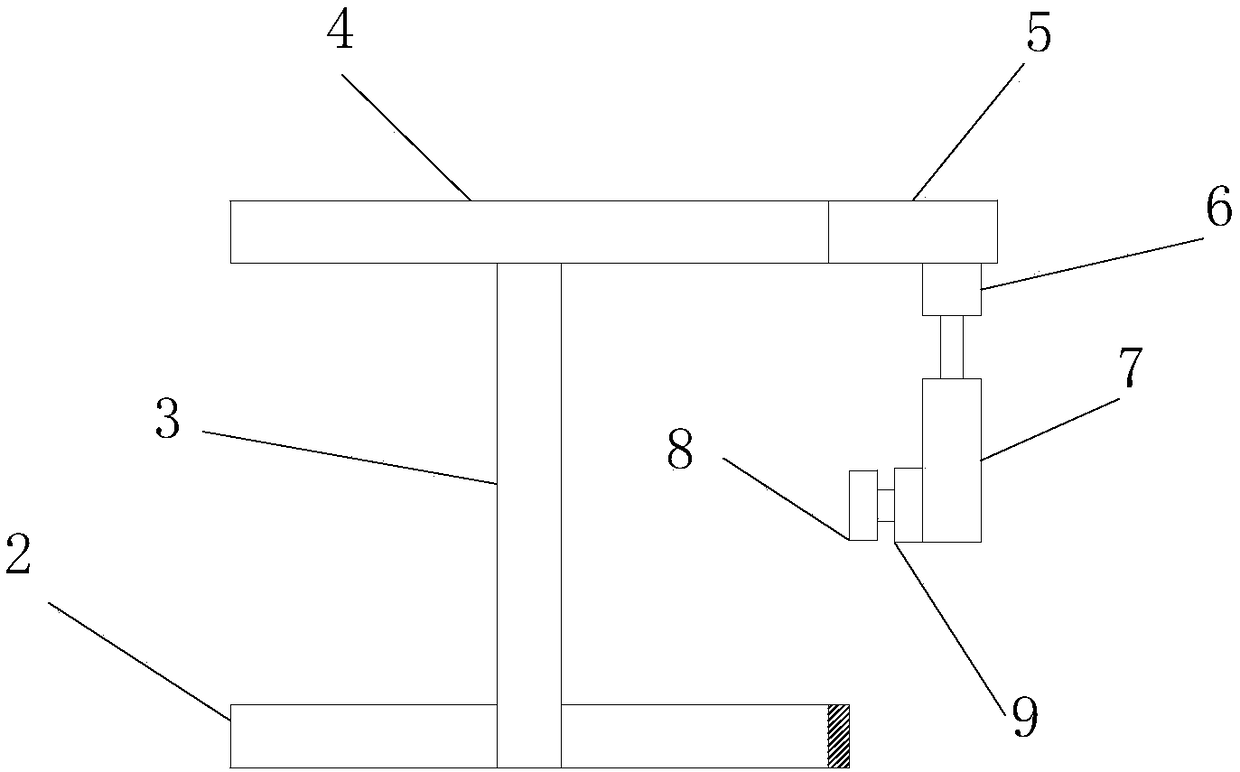

[0017] Such as figure 1 , figure 2 as shown, figure 1 It is a structural schematic diagram of a machine tool for grinding the outer surface of an arc-shaped thin-walled part proposed by the present invention; figure 2 It is a structural schematic diagram of a grinding mechanism in a machine tool for grinding the outer surface of an arc-shaped thin-walled part proposed by the present invention.

[0018] refer to figure 1 , figure 2 , a machine tool for grinding the outer surface of arc-shaped thin-walled parts proposed by the present invention, comprising a base 1, three support plates 2, three rotating shafts 3, three first driving mechanisms and three grinding mechanisms; wherein:

[0019] The three support plates 2 have different diameters, and the three support plates 2 are all fixedly installed on the base 1. 2 above are provided with a turntable 4 coaxially arranged therewith. Both sides of the three support plates 2 are provided with a first clamping device and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com