Multifunctional casting deburring workbench

A workbench and deburring technology, applied in the direction of manufacturing tools, metal processing equipment, grinding machine parts, etc., can solve the problems of low deburring efficiency, damage to the surface flatness or coating of the workpiece, etc., and achieve high deburring efficiency, Long service life, realize the effect of assembly line operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

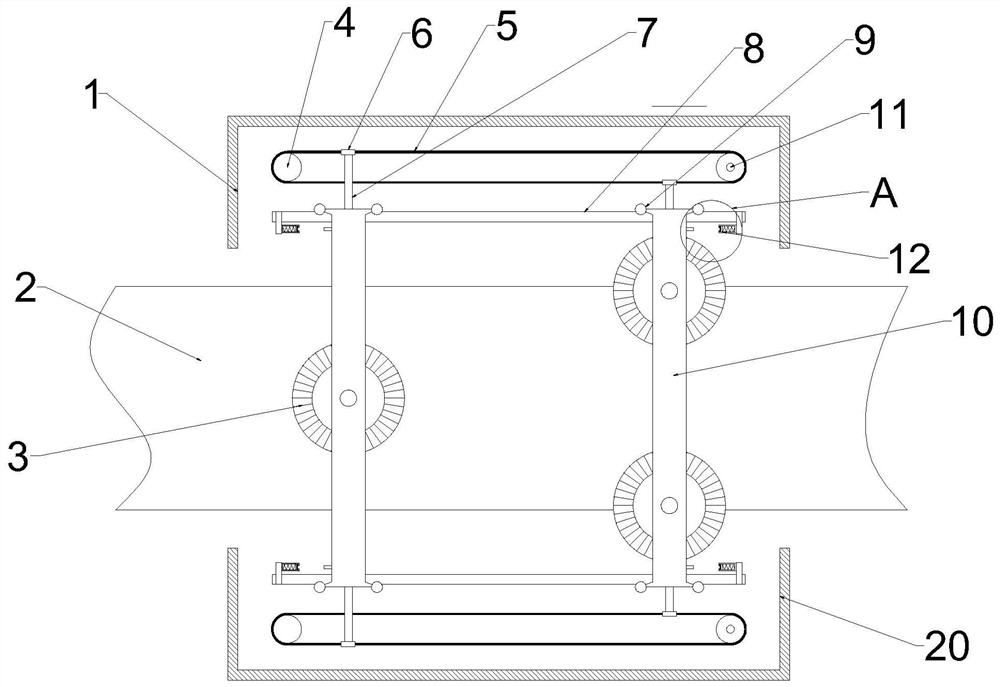

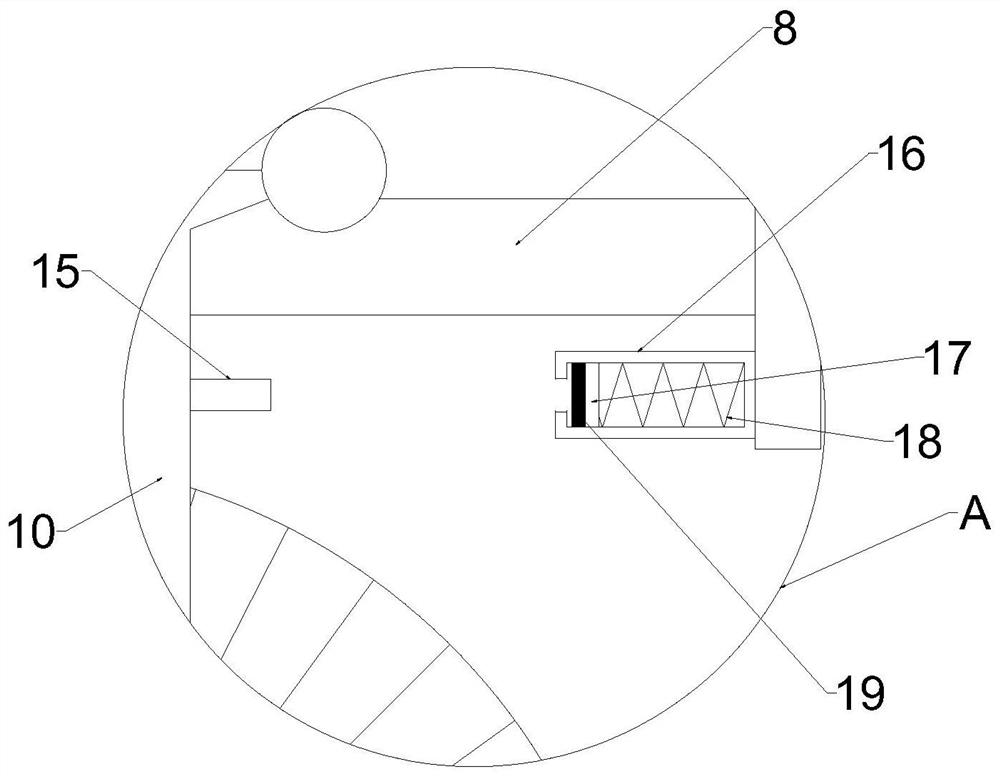

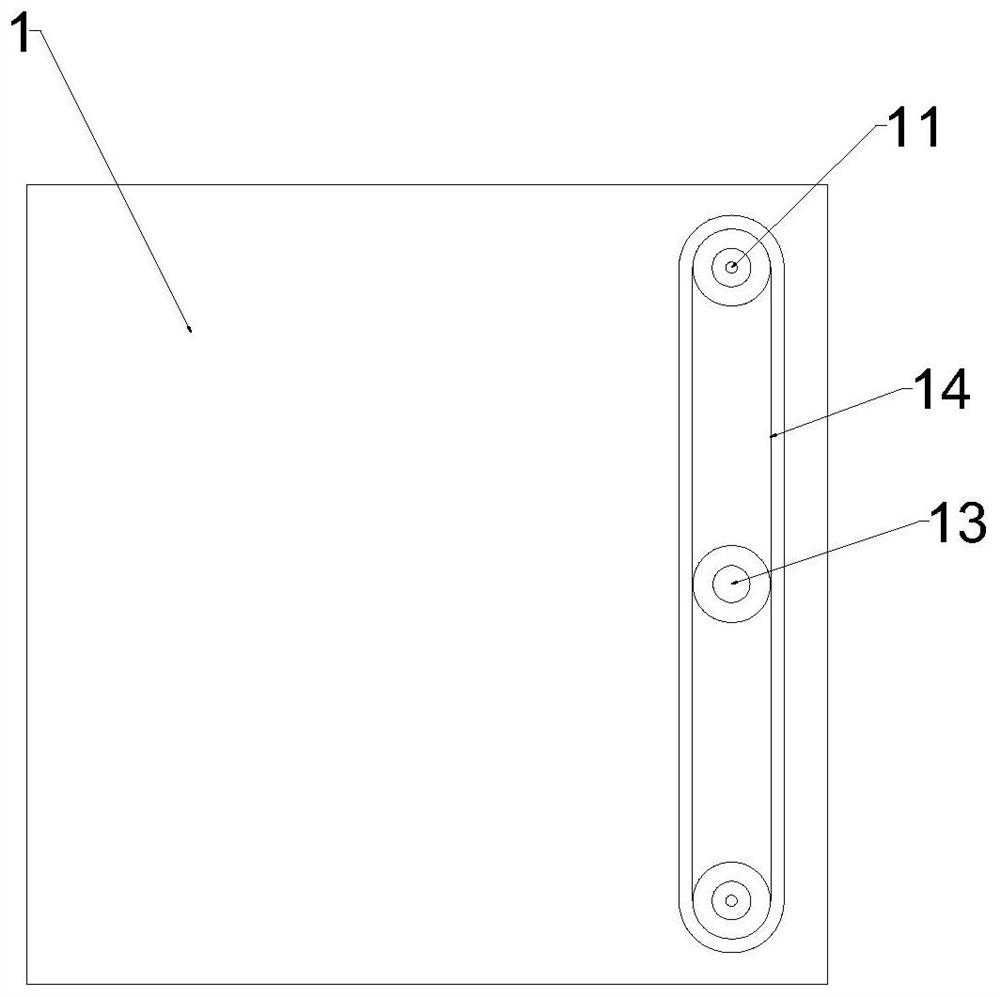

[0017] see Figure 1-Figure 3 , a multi-functional casting deburring workbench, including a casing 1 and a grinding disc 3, the grinding disc 3 is installed inside the casing 1; a workbench 2 is arranged under the casing 1, so that castings are placed on the workbench 2 , and then grind and deburr through the grinding disc 3, the continuous grinding and deburring operation of the casting can be realized, and the efficiency of grinding and deburring is greatly improved; Front and rear dislocation settings, the front and rear ends of the installation top plate 10 are provided with pulleys 9, and the pulleys 9 are slid left and right and installed on the slide rail 8, and the installation top plate 10 is connected and fixed with the fixed block 6 through the connecting rod 7. The fixed block 6 is installed on the transmission belt 5, and the transmission belt 5 is clamped on the transmission pulley 4, so that the transmission belt 5 is driven to reciprocate left and right by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com