High-precision workpiece polishing machine tool

A high-precision, grinding mechanism technology, applied in the direction of grinding machine parts, grinding machine, workpiece feed movement control, etc., can solve the problems of poor versatility, increased cost, and low productivity of the whole line.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

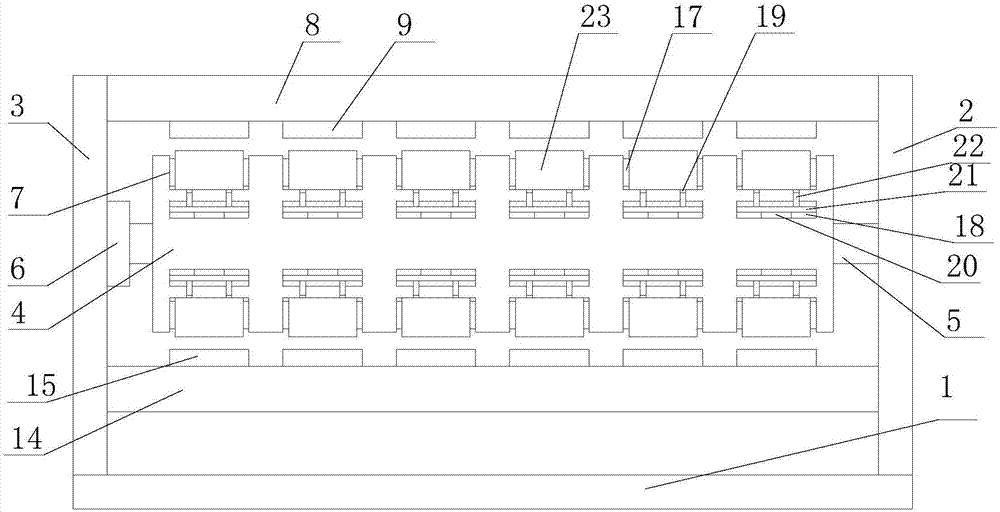

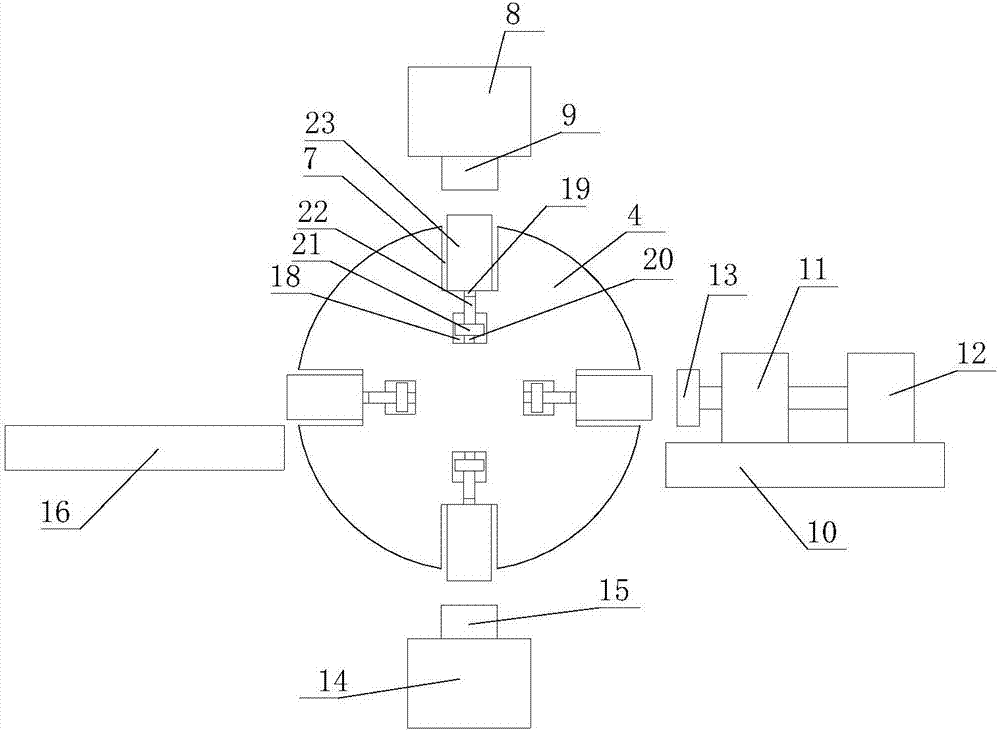

[0019] refer to figure 1 , figure 2 , the present invention proposes a high-precision workpiece grinding machine tool, including a base 1 and a workpiece fixing mechanism, wherein:

[0020] The base 1 is arranged horizontally, and a first side frame 2 and a second side frame 3 are arranged vertically at both ends of the base 1 in the length direction.

[0021] The workpiece fixing mechanism includes a roller 4, a rotating shaft 5 and a first driving mechanism 6. The roller 4 is located above the base 1 and the axial direction of the roller 4 is consistent with the length direction of the base 1. There are four rows of workpieces arranged circumferentially on the outer wall of the roller 4. Fixing grooves 7, each row of workpiece fixing grooves 7 includes six workpiece fixing grooves 7 arranged at intervals along the axial direction of the roller 4, and each workpiece fixing groove 7 is provided with two oppositely arranged clamping assemblies for clamping workpieces , the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com