Polishing device for automobile mechanical key blank machining

A technology for mechanical keys and automobiles, which is used in grinding drive devices, grinding/polishing safety devices, metal processing equipment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

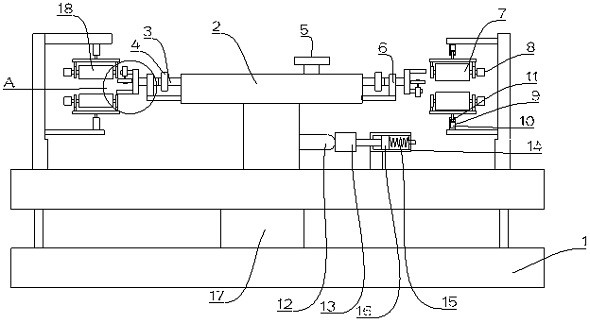

[0029] See Figure 1 ~ 2 , In the first embodiment of the present invention, a structural diagram of a polishing apparatus for automotive mechanical key embryo processing provided by the embodiment of the present invention, including: base 1;

[0030] Intermittent rotation is set to the mounting disk 2 on the base 1;

[0031] The mounting disk 2 is provided with a plurality of clamping components for clamping the part;

[0032] Two sets of grinding assemblies and cleaning assemblies on the base 1;

[0033] The two sets of grinding assemblies are connected;

[0034] And, the flip mechanism is provided between the two sets of grinding assemblies, which is used to enable the clamping assembly to make the parts grind between two sets of grinding assemblies in two sets.

[0035] Specifically, the part required to be polished is clamped on the clamp assembly of the upper position, and then the mounting disc 2 is rotated, so that the clamped part enters into the first set of grinding asse...

Embodiment 2

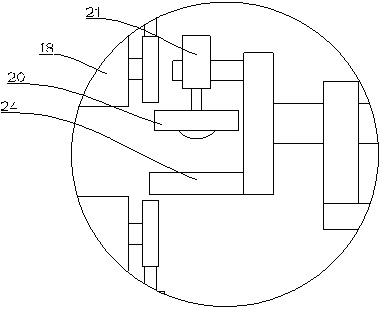

[0037] See Figure 1 ~ 4 The main difference from the first embodiment and the first embodiment is that the clamping assembly includes a curved rod 3 that is rotatably disposed on the mounting disk 2, and the rod 3 is provided with a first clamping member 20 and a second clip. Tight member 24, the first clamping member 20 and the second clamping member 24 are used to clamp the parts.

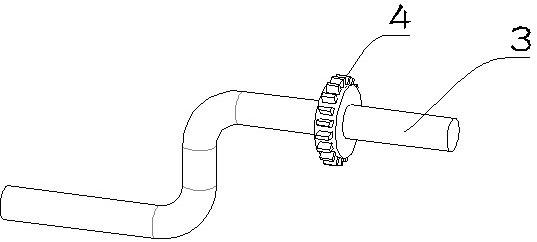

[0038] Such as figure 1 , 3 As shown, as a preferred embodiment of the present invention, the flip of the rod 3 is realized, so the flip mechanism includes a gear 4 and a curved rack 5 fixed to the base 1 on the base 6. The curved rack 5 is disposed on the movement trajectory of the gear 4, and the gear 4 passes through the curved rack 5 during rotation of the curved rod 3, which in turn has a rotation of the gear 4 to rotate 180 °, so that The part is flipped.

[0039] The cleaning assembly and the grinding assembly may also be provided with curved rack 5, so that the clamping assembly can be recove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com