Shaft high grinder

A technology of shaft height and grinding machine, which is applied in the direction of grinding machine parts, grinding machine, grinding feed movement, etc., can solve the problem of large size deviation of tile-shaped magnet shaft, and achieve improved grinding accuracy, reduced volume, The effect of reducing size deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

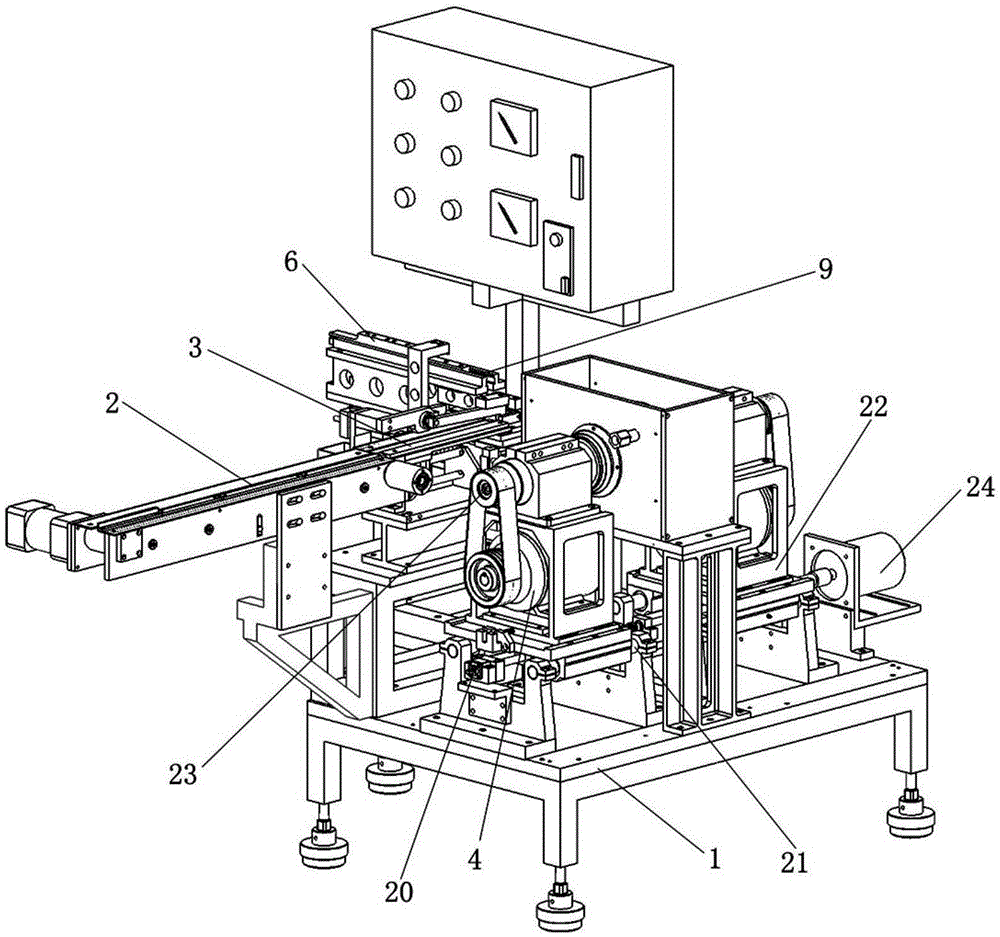

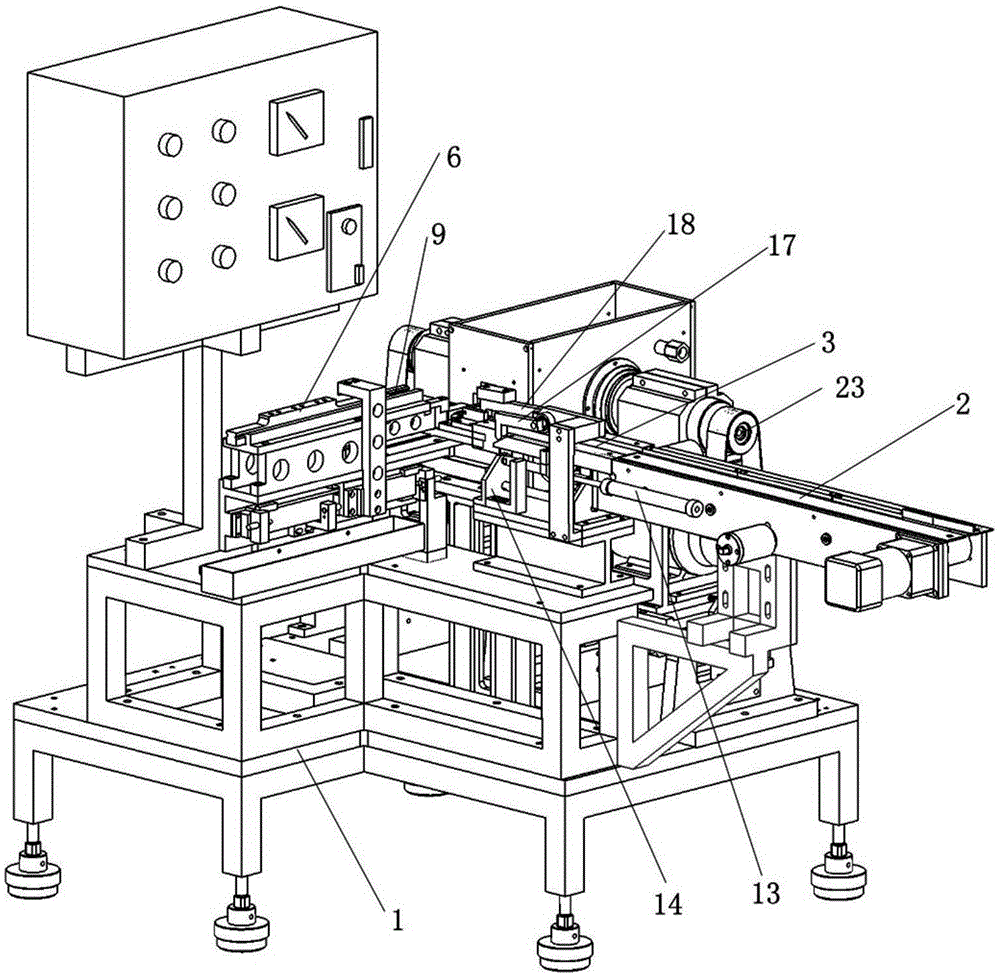

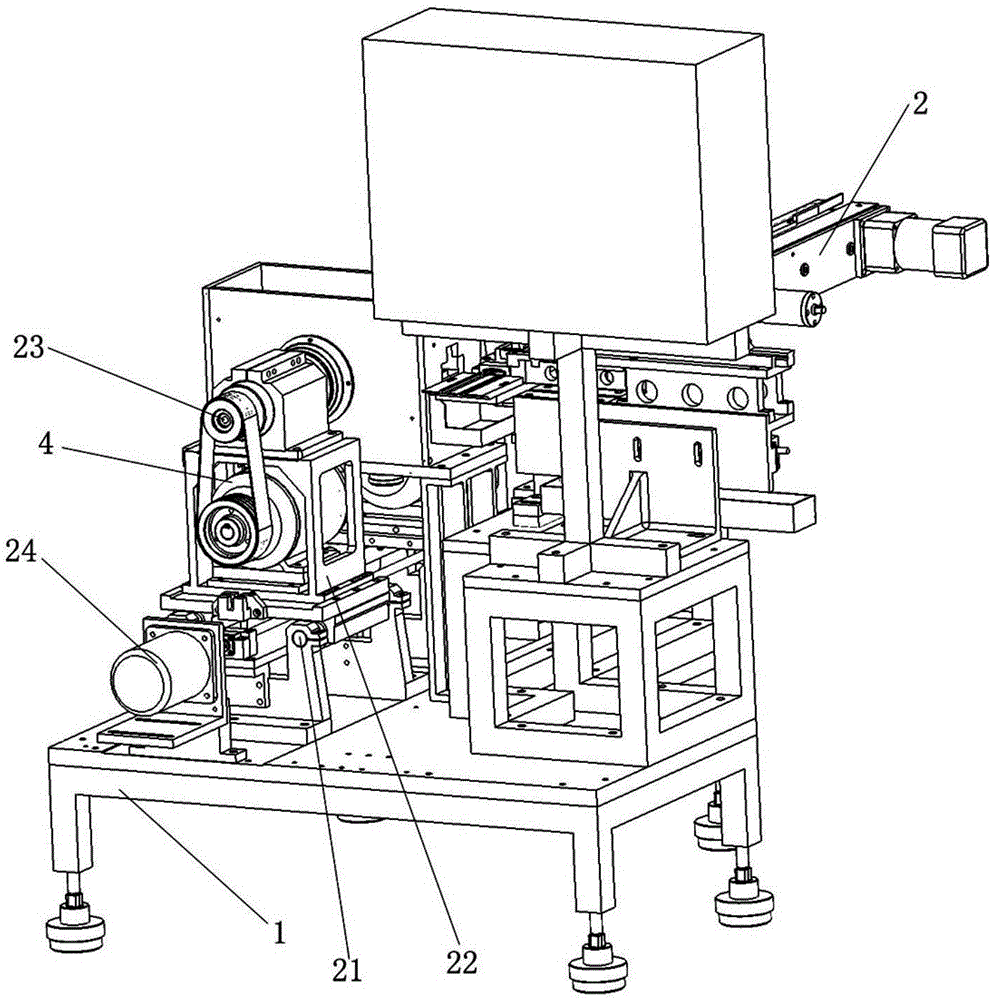

[0044] Such as Figure 1 to Figure 4 The shaft high mill shown includes the following components:

[0045] ① Rack 1.

[0046] ②Conveyor belt 2 set horizontally on frame 1.

[0047] ③ The first guide rail 3 is arranged in front of the conveyor belt 2, and the first guide rail 3 is supported by the frame 1.

[0048]④ Two grinding wheels 5 are set on the frame 1 and driven by the motor 4 and can move in opposite directions or opposite directions. The axes of the two grinding wheels 5 are collinear and parallel to the conveyor belt 2. The mechanism is as follows: four guide rods 21 are arranged horizontally on the frame 1, the guide rods 21 are perpendicular to the second guide rail 10, the motor base 22 is arranged on the guide rods 21, and the bottom of the motor base 22 has two through holes, two of which Two guide rods 21 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com