Polishing treatment device for inner wall of bent pipe fitting

A processing device and a technology for bending tubes, which are applied in grinding/polishing equipment, machine tools designed for grinding the rotating surface of workpieces, grinding machines, etc., can solve the problem of grinding head wear, oil hindering oil flow rate, and easy to be eroded by grinding fluid and other problems, to achieve the effect of increasing the impact force, reducing interference and obstruction, and shortening the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

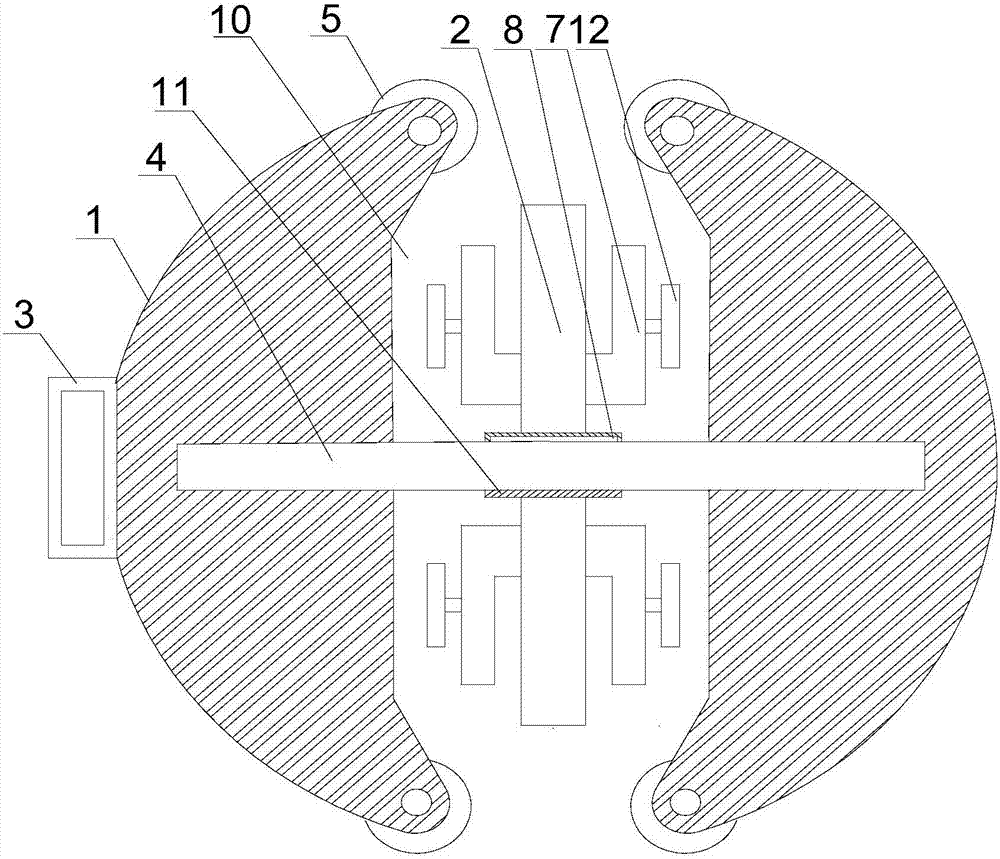

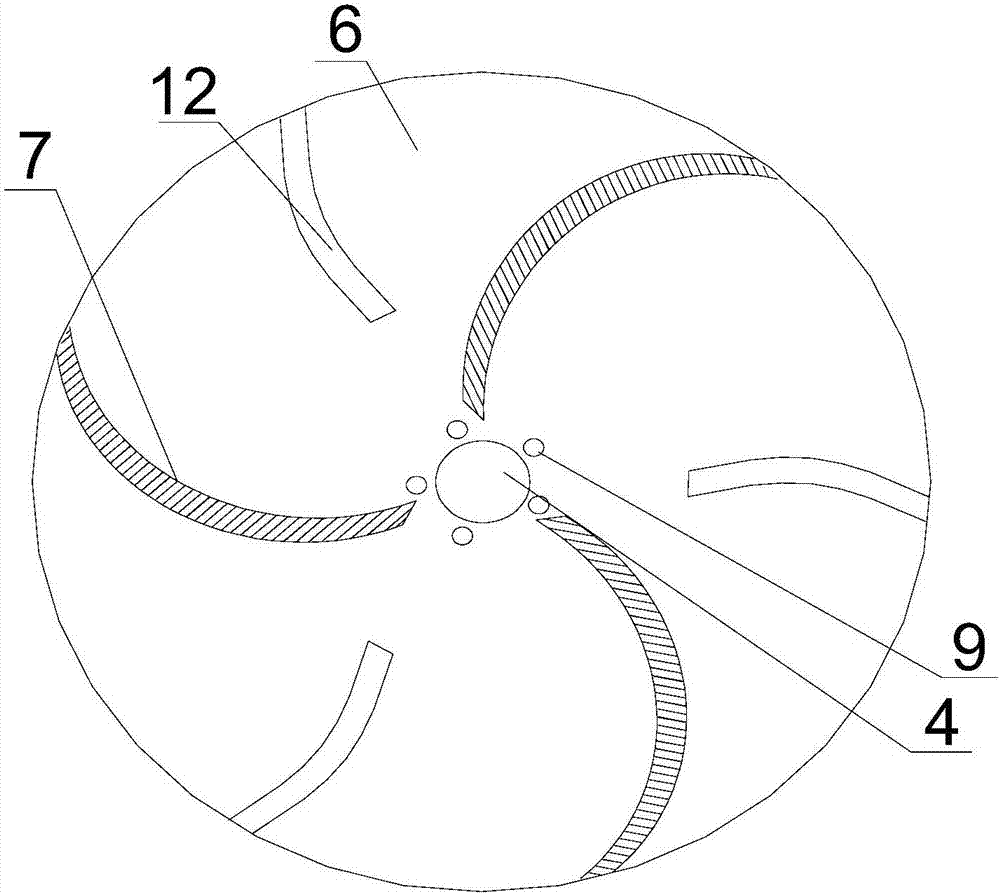

[0025] Such as figure 1 and figure 2 As shown, this embodiment includes two semi-spherical bodies 1 oppositely arranged and a central shaft 4 for connecting the two semi-spherical bodies 1, a sleeve 11 is arranged in the middle of the central shaft 4, along the axis of the central shaft 4 The outer wall in the middle is provided with a strip-shaped protrusion 8, and a groove cooperating with the protrusion 8 is formed on the inner peripheral wall of the sleeve 11, and the protrusion 8 can rotate freely in the groove around the axis of the central shaft 4, A wheel 2 is installed on the outer peripheral wall of the sleeve 11, the wheel 2 includes a body 6, the body 6 is arranged on the sleeve 11, and a plurality of arc-shaped holes are arranged on both sides of the body 6 Blades 7 form leaf grooves between two adjacent blades 7, and pulleys 5 are installed at the ends of the upper and lower ends of the semicircular body 1; a plurality of adjusting rudders 12 are also included,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com