Grinding device of glass plate

A glass plate and grinding technology, which is applied in the direction of grinding/polishing equipment, grinding machines, and machine tools suitable for grinding the edge of workpieces, etc., can solve the problems of inability to grind continuously, supply glass plates, and enlarge the equipment site, etc., to achieve Improved productivity and continuous grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

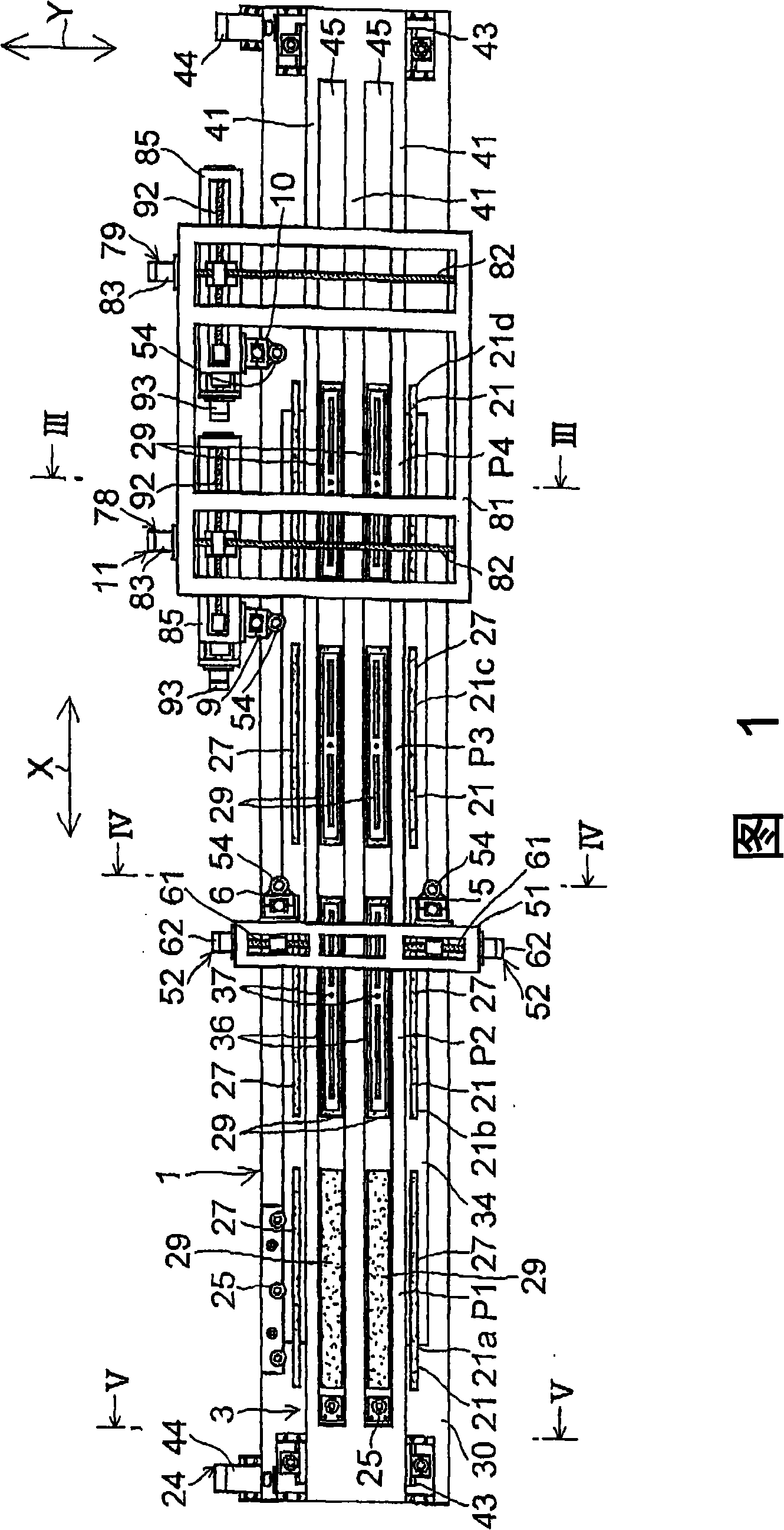

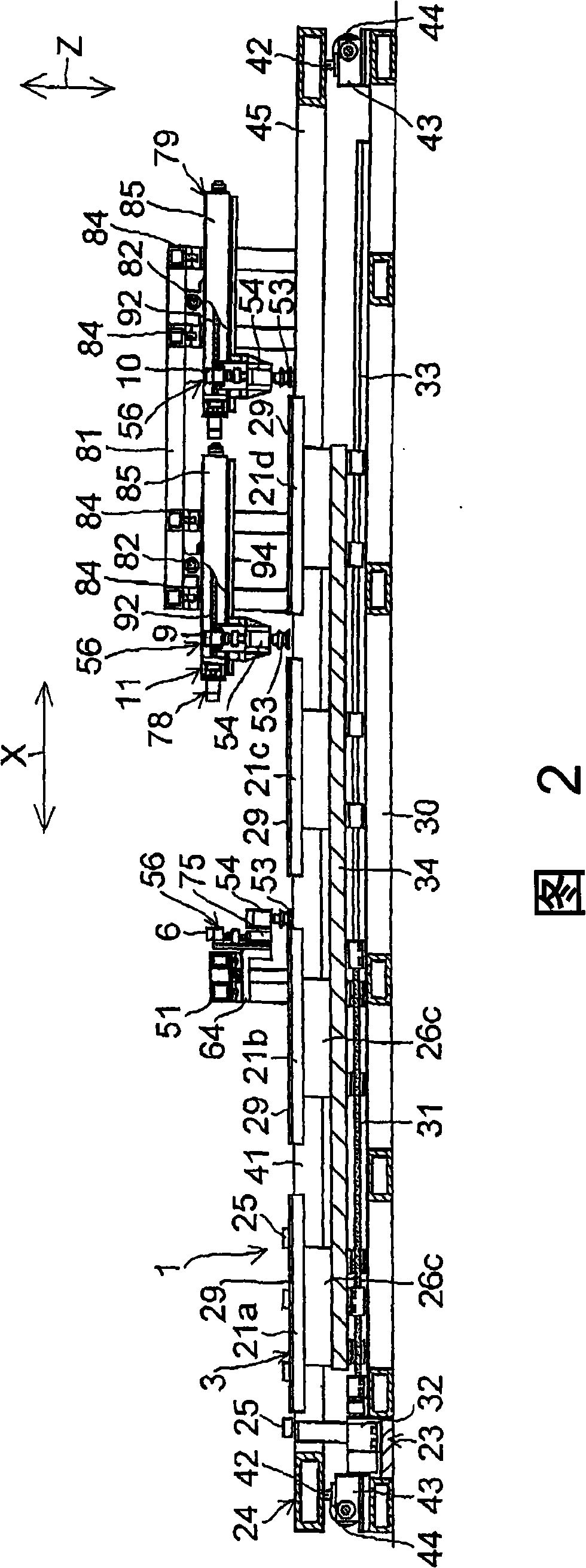

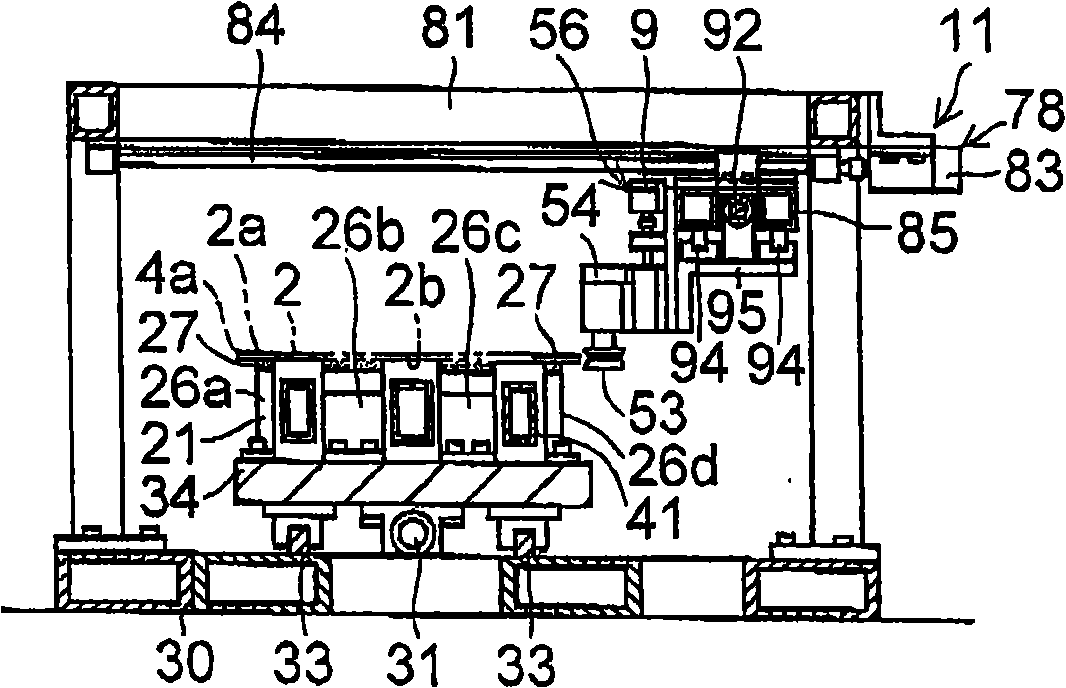

[0020]From Fig. 1 to Fig. 7, the glass plate grinding device 1 of this example has: the linear conveying unit shown in Figs. 3; a first grinding device with fixed grinding heads 5 and 6, which respectively grind the two side edges 4a and 4b extending in the X direction of the glass plate 2 linearly transported by the linear transport unit 3; Grinding; the second grinding device with movable grinding heads 9 and 10, the grinding heads 9 and 10 are adjacent to the first grinding device in the X direction, and are respectively linearly transported by the linear transport unit 3 The front edge 7 and the trailing edge 8 extending along the Y direction perpendicular to the X direction of the glass plate 2 are ground, so that these grinding heads 9 and 10 follow the front edge of the glass plate 2 linearly transported by these transport units 3. The edge 7 and the trailing edge 8 cross-cut the channel of the glass plate 2 obliquely, and the second grinding device has: the respective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com