Aramid fiber-reinforced high-temperature-resistant nylon composite material and preparation method thereof

A nylon composite material and aramid fiber technology, which is applied in the field of polymer material processing, can solve the problems of easy exposure of fiber reinforcements, uneven distribution of fillers, poor compatibility, etc., and achieve stable product quality, simple preparation methods and processes , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The main equipment used in the production of aramid fiber-reinforced high-temperature-resistant nylon composite materials used in this embodiment includes:

[0041] High-speed mixer, speed 450~1350r / min;

[0042] Twin-screw extruder, screw speed: 230~400rpm, set temperature: 285~305℃;

[0043] Water tank: cooling water temperature 25~45℃, pelletizer speed: 400~800rpm;

[0044] The high temperature resistant nylon is made of PA10T, which is provided by Shanghai Jieshijie New Materials (Group) Co., Ltd. Before use, put it in a drying oven and dry it at 100°C for 8 hours.

[0045] The aramid fiber is selected from the Tametar meta-aramid staple fiber provided by Yantai Taihe New Materials Co., Ltd., and is treated with diphenylmethane diisocyanate before use. The weight ratio of aramid fiber to diphenylmethane diisocyanate is 30%.

[0046] The compatibilizer is selected from maleic anhydride grafted SEBS;

[0047] The processing aid is a mixture of phenolic high-tempera...

Embodiment 2

[0056] The difference between this embodiment and Example 1 is that each raw material is weighed in the following parts by weight:

[0057] Aramid fiber 20 parts,

[0058] 70 parts of high temperature resistant nylon,

[0059] 20 parts of compatibilizer,

[0060] 3 parts of processing aids.

[0061] The high temperature resistant nylon is PA9T, which is provided by Shanghai Jieshijie New Materials (Group) Co., Ltd.

[0062] All the other processing steps are the same as in Example 1.

Embodiment 3

[0064] The difference between this embodiment and Example 1 is that each raw material is weighed in the following parts by weight:

[0065] 30 parts of aramid fiber,

[0066] 70 parts of high temperature resistant nylon,

[0067] 20 parts of compatibilizer,

[0068] 3 parts of processing aids.

[0069] All the other processing steps are the same as in Example 1.

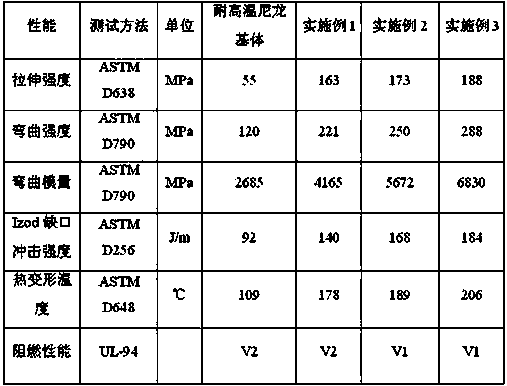

[0070] For the products obtained in Example 1-Example 3, ASTM standards were used to test its comprehensive mechanical properties and flame retardant properties, including tensile strength, flexural strength, flexural modulus, Izod notched impact strength and heat distortion temperature. The test results are shown in Table 1 below.

[0071] Table 1

[0072]

[0073] As can be seen from Table 1, the mechanical properties, high temperature resistance and flame retardancy of the aramid fiber / high temperature resistant nylon composite material with aramid fiber as a reinforcing agent in the examples of the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com