Defect cutting device for capacitor-used metalized film

A metallized film and capacitor technology, applied in capacitors, capacitor manufacturing, circuits, etc., can solve the problems of poor surface smoothness of the film, stoppage of film continuous transmission, waste of production resources, etc., achieve significant practical value, ensure continuity, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

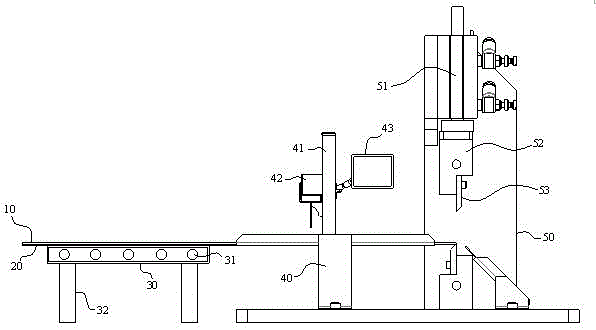

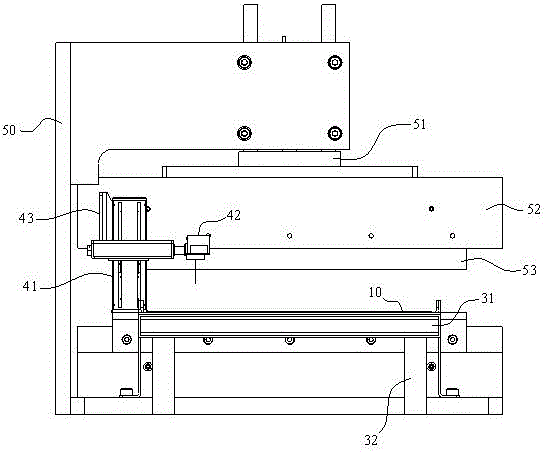

[0013] like figure 1 , figure 2 As shown, the present invention provides a defect cutting device for metallized films for capacitors, which includes a light-transmitting plate 20, a light-emitting device 31 is arranged under the light-transmitting plate 20, and a metallized film is laid on the light-transmitting plate 20. film 10, the light emitted by the light-emitting device 31 sequentially passes through the light-transmitting plate 20 and irradiates the back of the metallized film 10, and a laser cutting device is installed at a position behind the light-transmitting plate 20 on the stroke of the metallized film 10, The laser cutting device includes a support frame 40 on which a movable arm 41 is disposed, and a laser 42 is disposed on the movable arm 41 . This technical solution cuts the defects of the film through a laser cutting device. Because the movable arm 41 is flexible, it can carry the laser 42 to move quickly. Because there are multiple capacitor films to be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com