Wear-resistant and high-temperature-resistant nylon composite material and preparation method thereof

A technology of nylon composite materials and high temperature resistance, applied in the field of polymer materials, can solve the problems of loss of mechanical properties of materials, clogging of extruder die heads, and broken bars, etc., to achieve stable product quality, improve wear resistance, and production high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

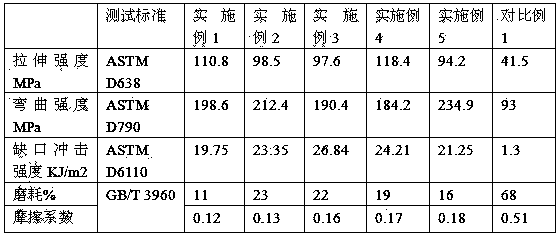

Examples

Embodiment 2

[0032] (1) Dry high-temperature-resistant nylon, nylon 66, wear-resistant agent, antioxidant, and lubricant at 120°C for 4 hours;

[0033] (2) Put 10 parts of nylon 66 and 5 parts of anti-wear agent molybdenum disulfide in a high-mixer, and stir for 5 minutes at 80°C and 1000 rpm; then add 85 parts of high-temperature resistant nylon PA6T, 0.1 parts Antioxidant 1010, 0.1 part of antioxidant 168, 0.4 part of lubricant barium stearate and mix well at room temperature.

[0034] (3) Put the mixed raw materials into the twin-screw extruder, melt and extrude to granulate. Zone 310°C, zone 6 300°C, zone 7 295°C, head 285°C, extrusion rate 300r / min.

[0035]

Embodiment 3

[0037] (1) Dry high-temperature-resistant nylon, nylon 66, wear-resistant agent, antioxidant, and lubricant at 80-120°C for 4-6 hours;

[0038] (2) Put 35 parts of nylon 66 and 5 parts of anti-wear agent molybdenum disulfide in a high-mixer, and stir for 5 minutes at 80°C and 1000 rpm; then add 65 parts of high-temperature resistant nylon PA6T, 0.2 parts Antioxidant 1010, 0.2 part of antioxidant 168, 0.8 part of lubricant zinc stearate and mix well at room temperature.

[0039] (3) Add the mixed raw materials into the twin-screw extruder, melt and extrude to granulate. Zone 310°C, zone 6 300°C, zone 7 295°C, head 285°C, extrusion rate 300r / min.

[0040]

Embodiment 4

[0042] (1) Dry high-temperature-resistant nylon, nylon 66, wear-resistant agent, antioxidant, and lubricant at 100°C for 5 hours;

[0043] (2) Put 25 parts of nylon 66 and 15 parts of anti-wear agent molybdenum disulfide in a high-mixer, and stir for 5 minutes at 80°C and 1000 rpm; then add 80 parts of high-temperature resistant nylon PA46, 0.2 parts Antioxidant 1010, 0.3 part of antioxidant 168, 0.6 part of lubricant barium stearate and mix well at room temperature.

[0044] (3) Add the mixed raw materials into the twin-screw extruder, melt and extrude to granulate. Zone 310°C, zone 6 300°C, zone 7 295°C, head 285°C, extrusion rate 300r / min.

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com