Patents

Literature

43results about How to "Simple extrusion process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet light crosslinking low-smoke zero-halogen flame-retardant cable material and preparation method thereof

ActiveCN104893088AImprove mechanical propertiesImprove flame retardant performancePlastic/resin/waxes insulatorsLow-density polyethylenePolymer science

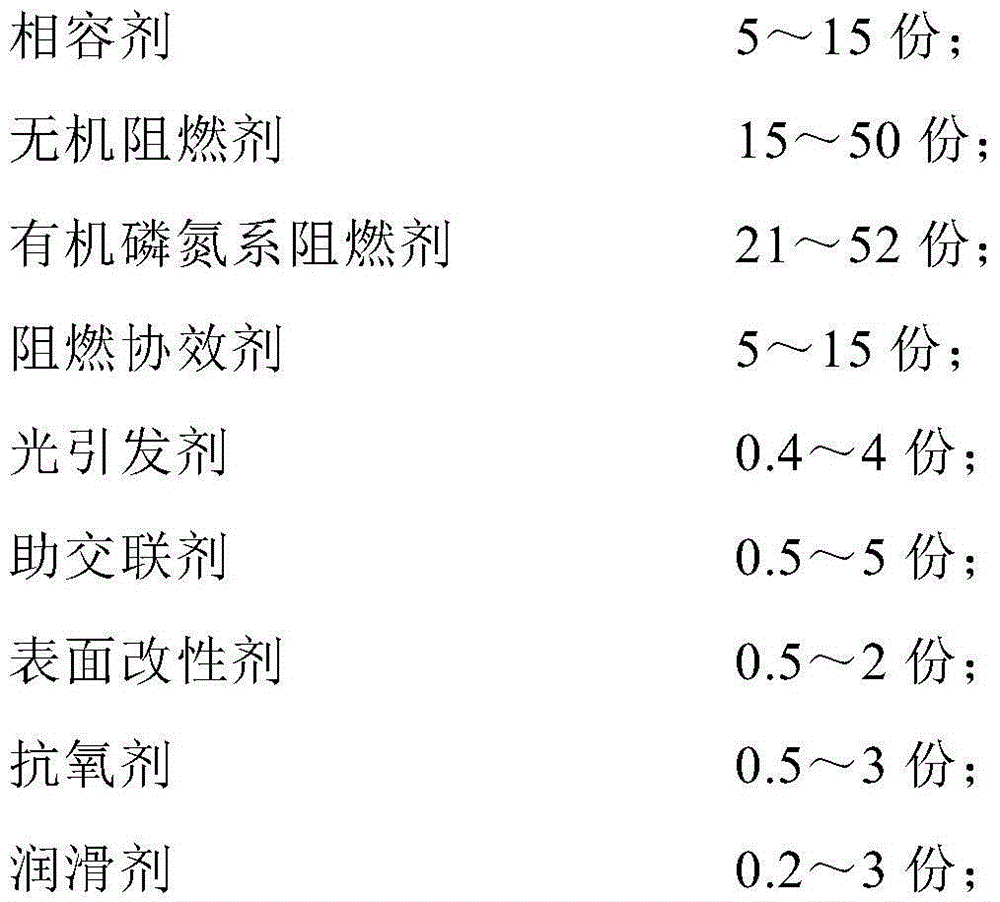

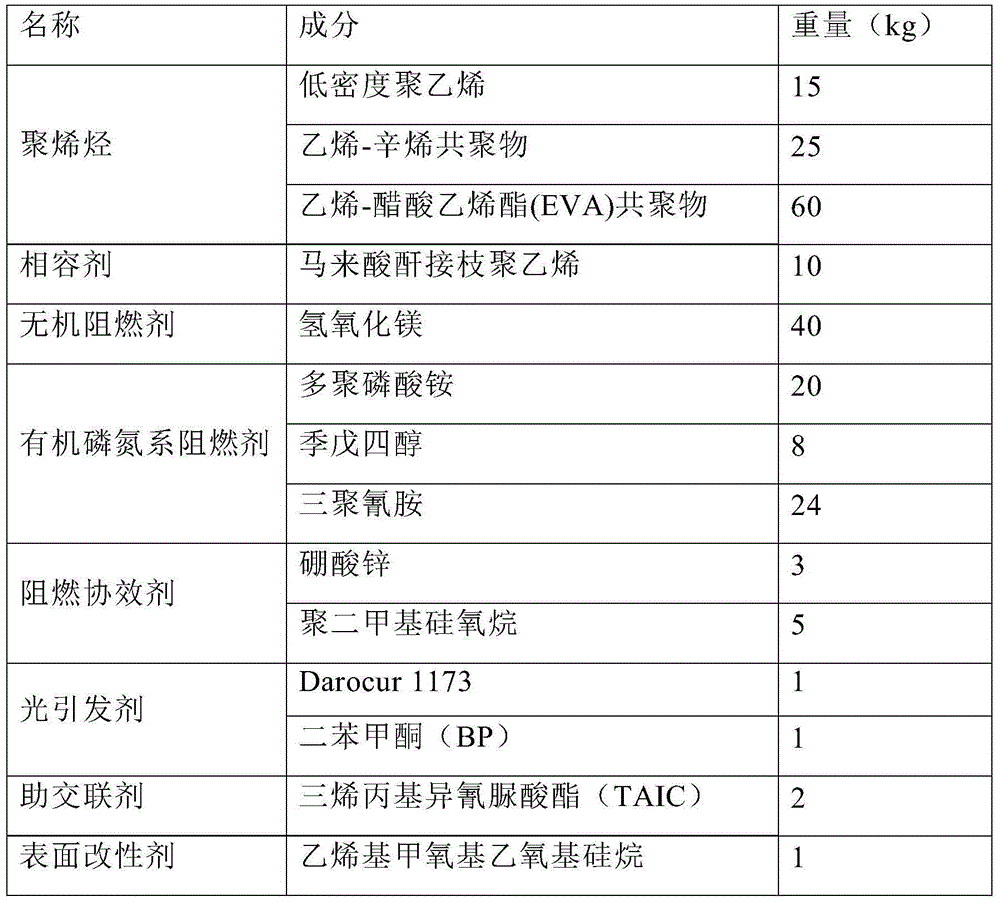

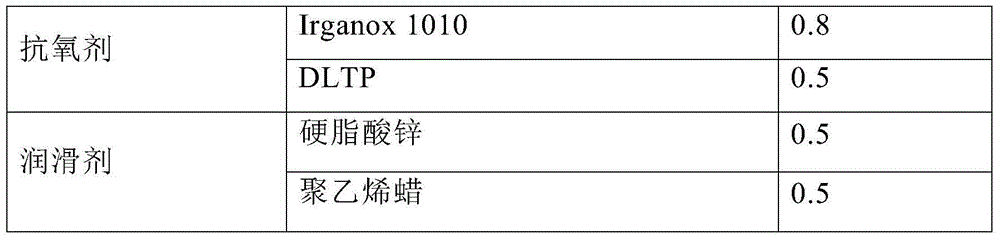

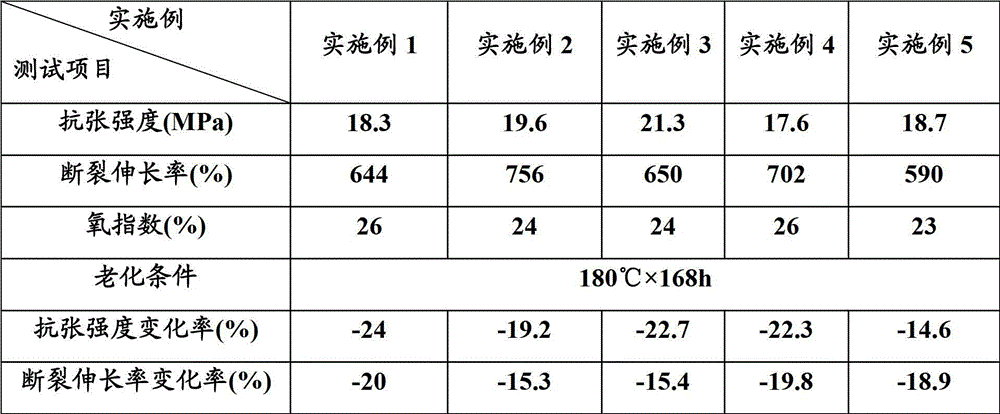

The invention provides an ultraviolet light crosslinking low-smoke zero-halogen flame-retardant cable material. The cable material comprises polyolefin, a compatilizer, an inorganic flame retardant, an organic phosphorus-nitrogen-containing flame retardant, a flame-retardant synergist, a photoinitiator, an assistant crosslinker, a surfactant, an antioxidant and a lubricant, wherein polyolefin contains low-density polyethylene, an ethylene-octylene copolymer and an ethylene-vinyl acetate copolymer in the weight proportion being (10-25):(20-35):(55-65); the compatilizer is polyethylene for grafting of maleic anhydride; the inorganic flame retardant is selected from magnesium hydroxide and aluminum hydroxide; the organic phosphorus-nitrogen-containing flame retardant contains polyphosphoric acid, pentaerythritol and melamine in the weight proportion being (10-20): (4-8): (15-30); the flame-retardant synergist contains zinc borate and / or polydimethylsiloxane. The cable material has good thermal resistance and anti-aging performance, can be used at the temperature of 125 DEG C for a long time and is excellent in comprehensive mechanical performance and better in flame retardance.

Owner:上海至正新材料有限公司

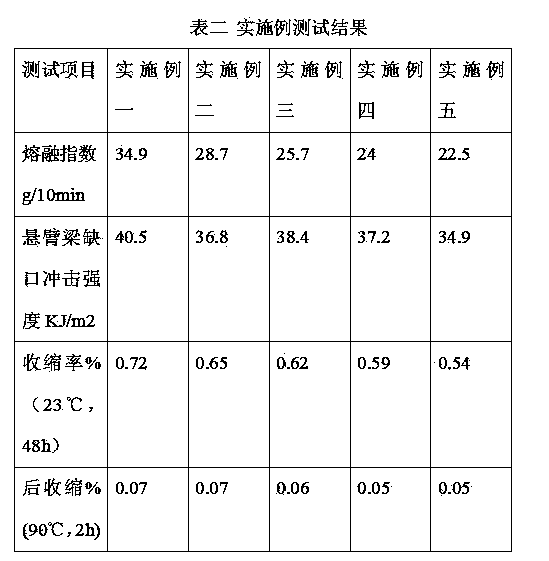

Polypropylene composition with high fluidity and high dimensional stability and preparation method thereof

ActiveCN103819817AGood dimensional stabilityHigh flow and high dimensional stabilityPolymer scienceLow speed

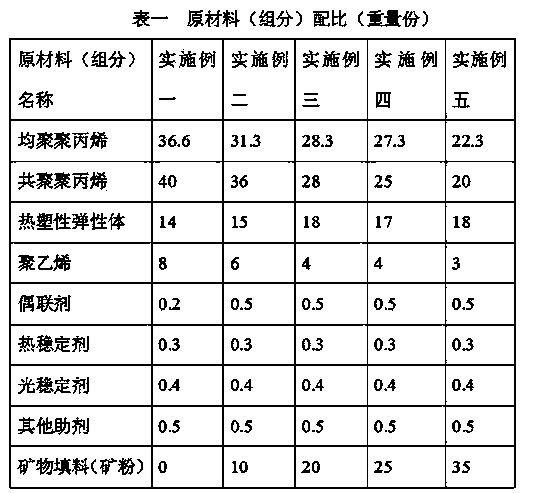

The invention discloses polypropylene composition with high fluidity and high dimensional stability and a preparation method thereof. The polypropylene composition with high fluidity and high dimensional stability comprises components in parts by weight as follows: 10-60 parts of homo-polypropylene, 10-40 parts of co-polypropylene, 10-25 parts of thermoplastic elastomer, 3-8 parts of polyethylene, 0-35 parts of mineral fillers, 0.2-1 part of a heat stabilizer, 0.2-1 part of a light stabilizer, 0.3-1 part of a coupling agent and 0.5-3 parts of other auxiliaries. The preparation method comprises the steps as follows: raw materials are weighed in the ratio in parts by weight; the raw materials are stirred and mixed for 2-8 min at a low speed to obtain a premixed material; and the premixed material is added into a double-screw extruder for melt blending and extruding granulation. According to the invention, a product has high fluidity, low shrinking percentage and good dimensional stability; and a production formula is mature, an extrusion process is simple, the product performance can be regulated according to the formula and is controllable, and an injection molding process has a wide range.

Owner:株洲时代工程塑料实业有限公司

Halogen-free flame retardant polyphenyl ether/polystyrene alloy material and preparation method thereof

The invention discloses a halogen-free flame retardant polyphenyl ether / polystyrene alloy material. The material comprises the following components by weight: 37-90 parts of polyphenyl ether, 10-50 parts of polystyrene, 5-20 parts of a flame retardant, 0.2-0.5 parts of an antioxidant and 5.1-35.1 parts of an assistant. The invention also discloses a preparation method of the halogen-free flame retardant polyphenyl ether / polystyrene alloy material. The PPO / PS alloy material provided by the invention has advantages of excellent property, low cost and energy saving, and can realize steel substitution by plastic. The added halogen-free flame retardant endows the alloy with good flame retardancy, is friendly to the environment, and does not cause secondary pollution. Besides, the material forming process is simple, and saves processing cost. Further, a section bar produced from the PPO / PS alloy material has wide application, and can be used for parts in special electronic and electrical appliances and large equipment, due to the advantages of good flame resistance, corrosion resistance, insulation, good strength and toughness, light resistance and light weight.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

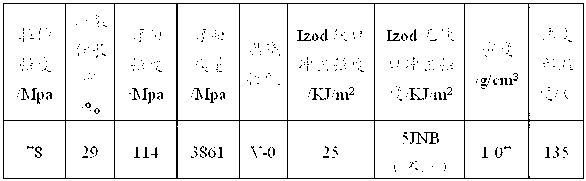

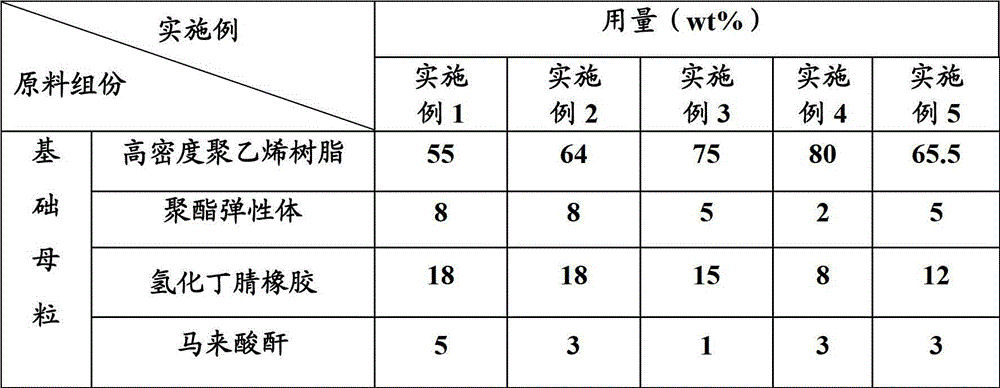

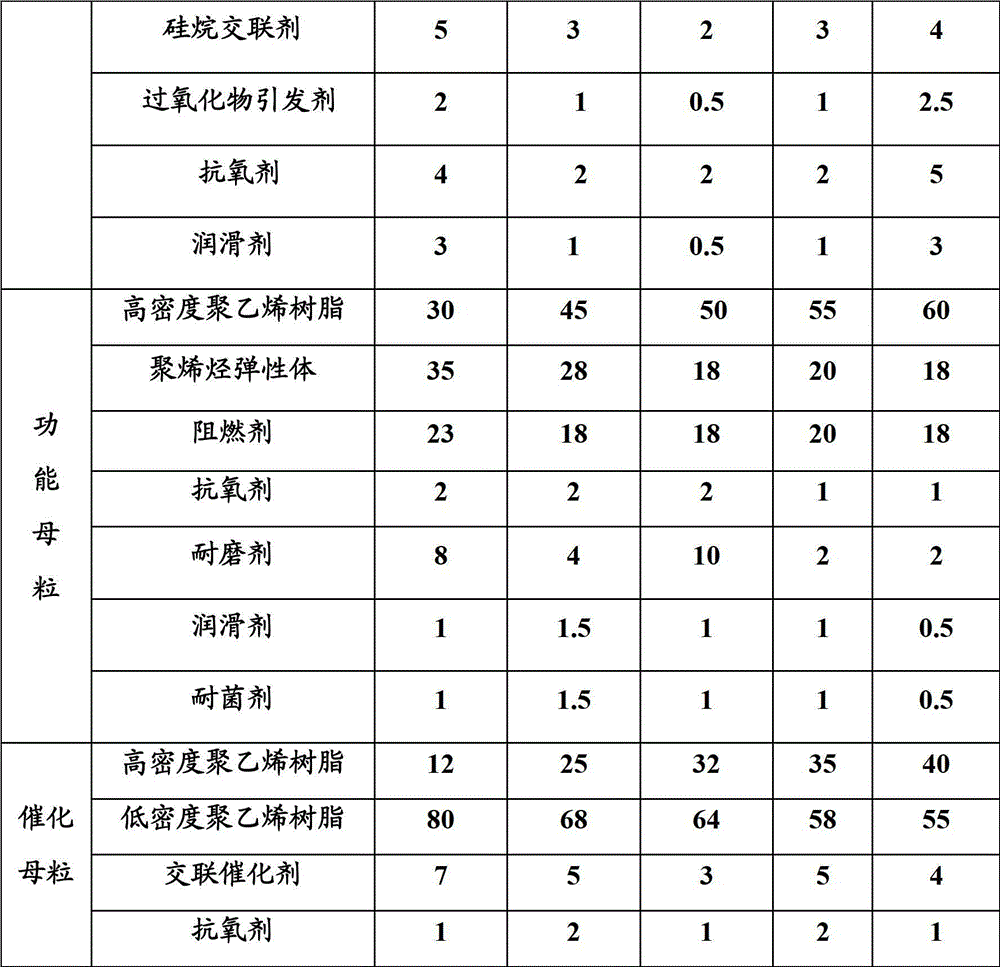

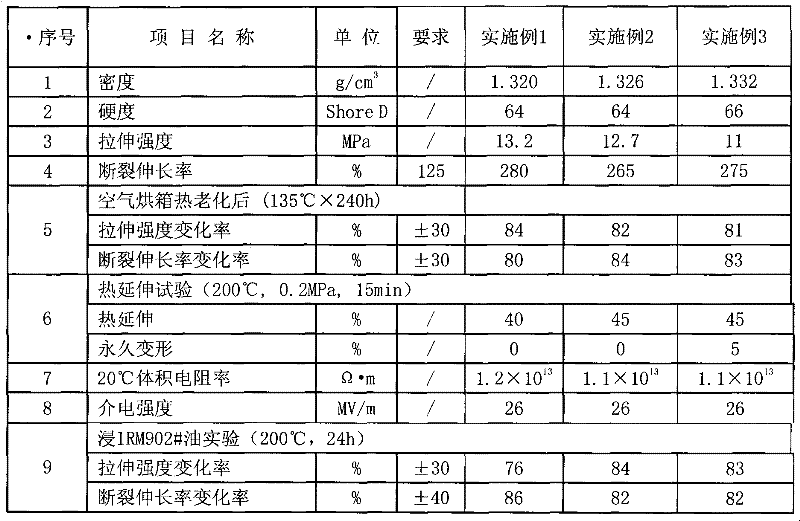

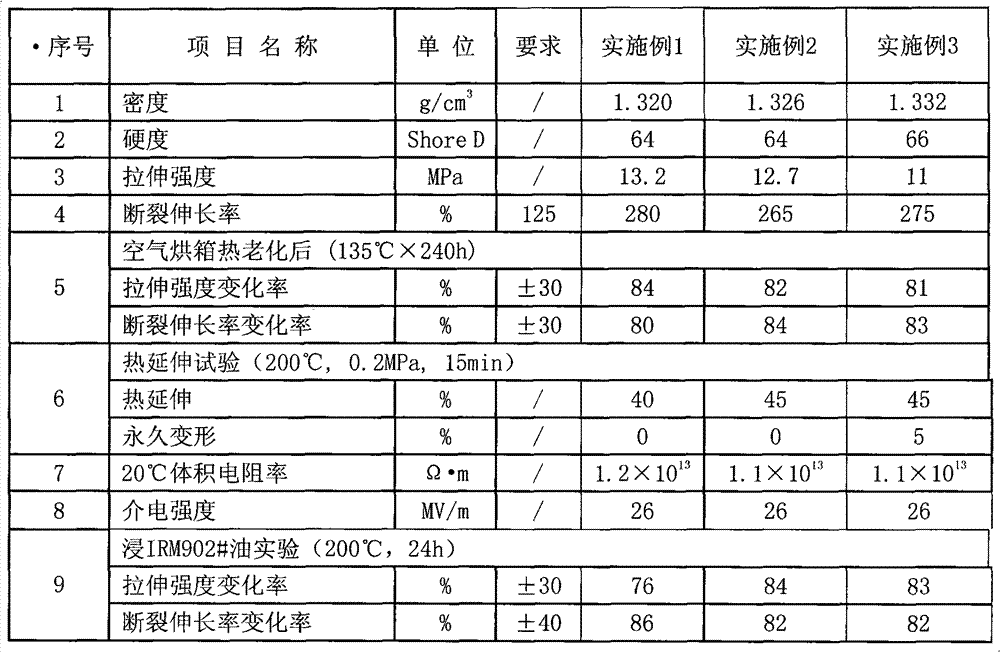

High-temperature-resistant silane-crosslinked flame-retardation insulating material for automobile wires and preparation method thereof

ActiveCN103059374AImprove aging resistanceImprove wear resistanceInsulated cablesCable/conductor manufactureLow-density polyethyleneElastomer

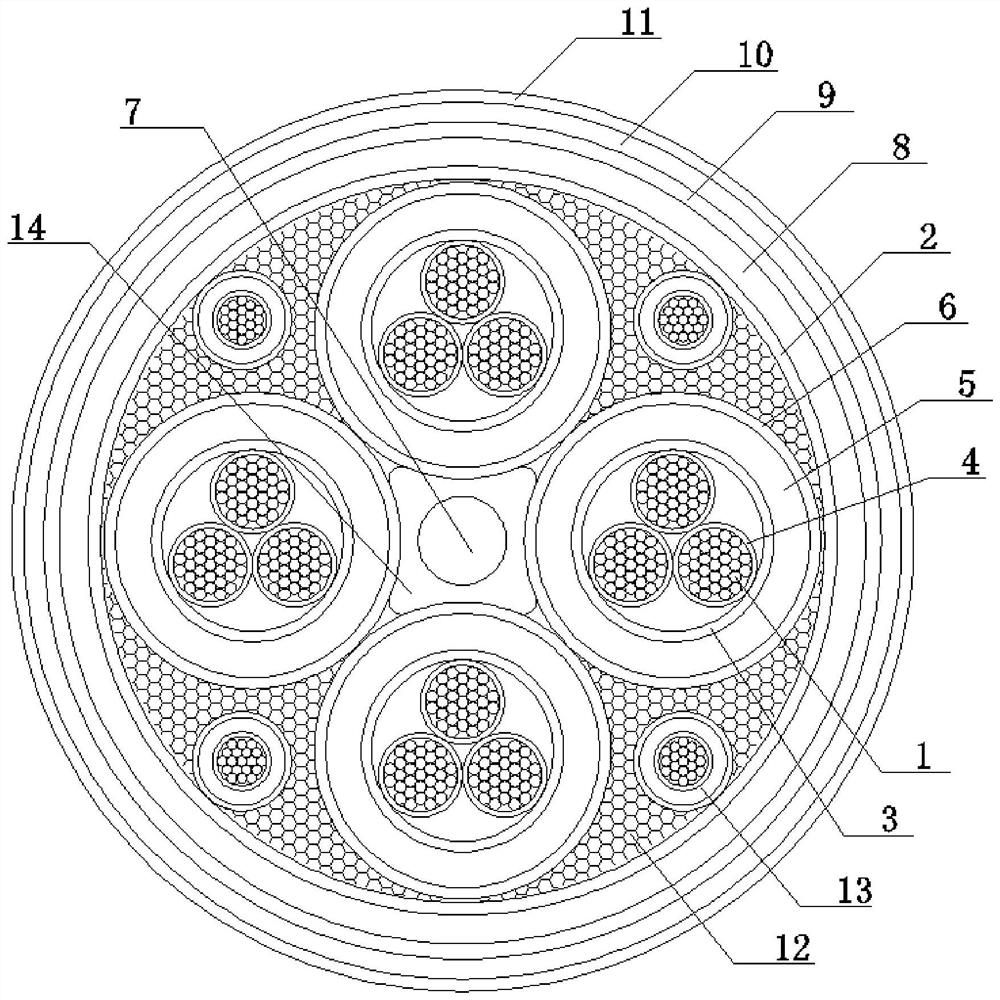

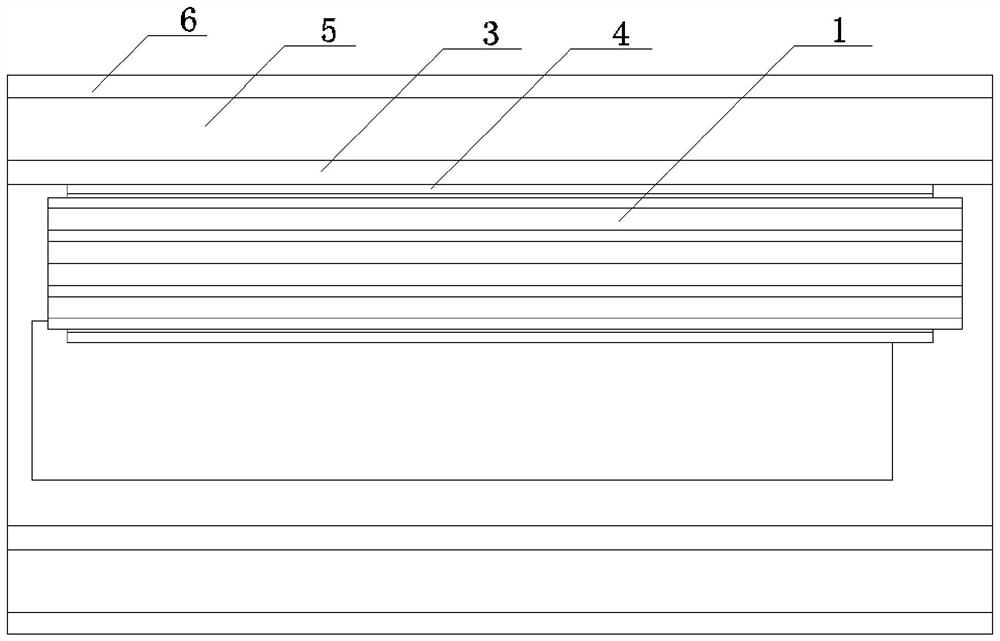

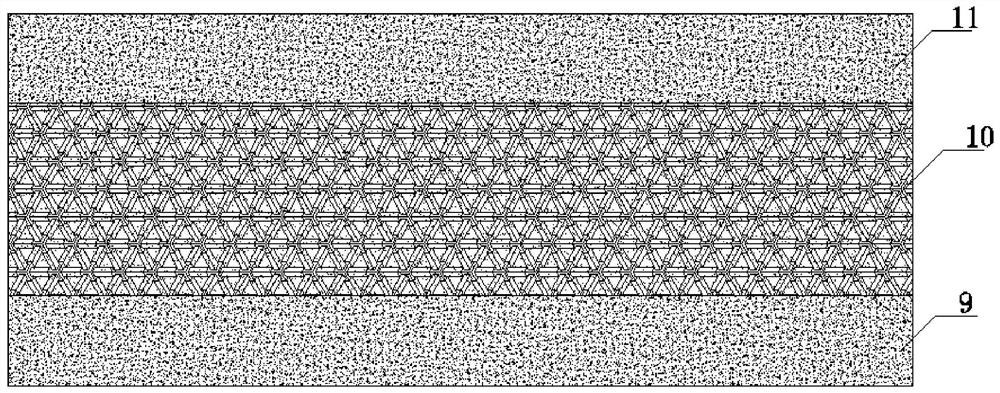

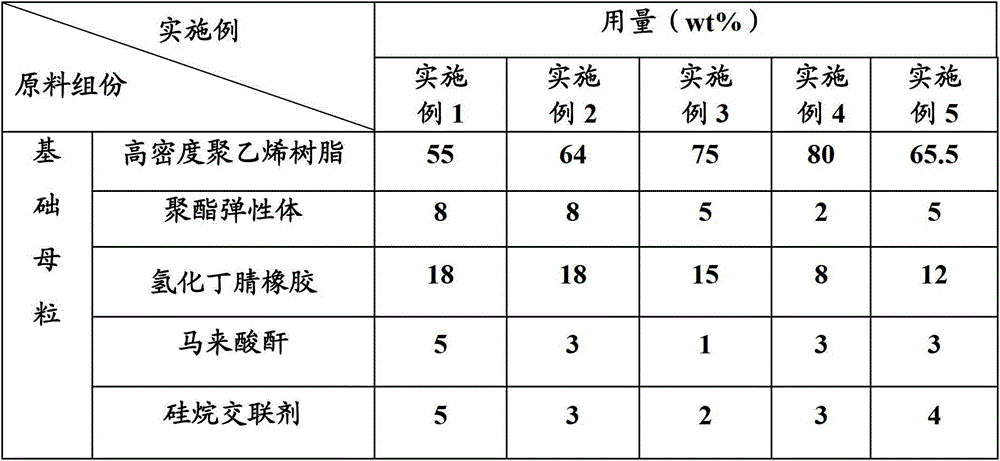

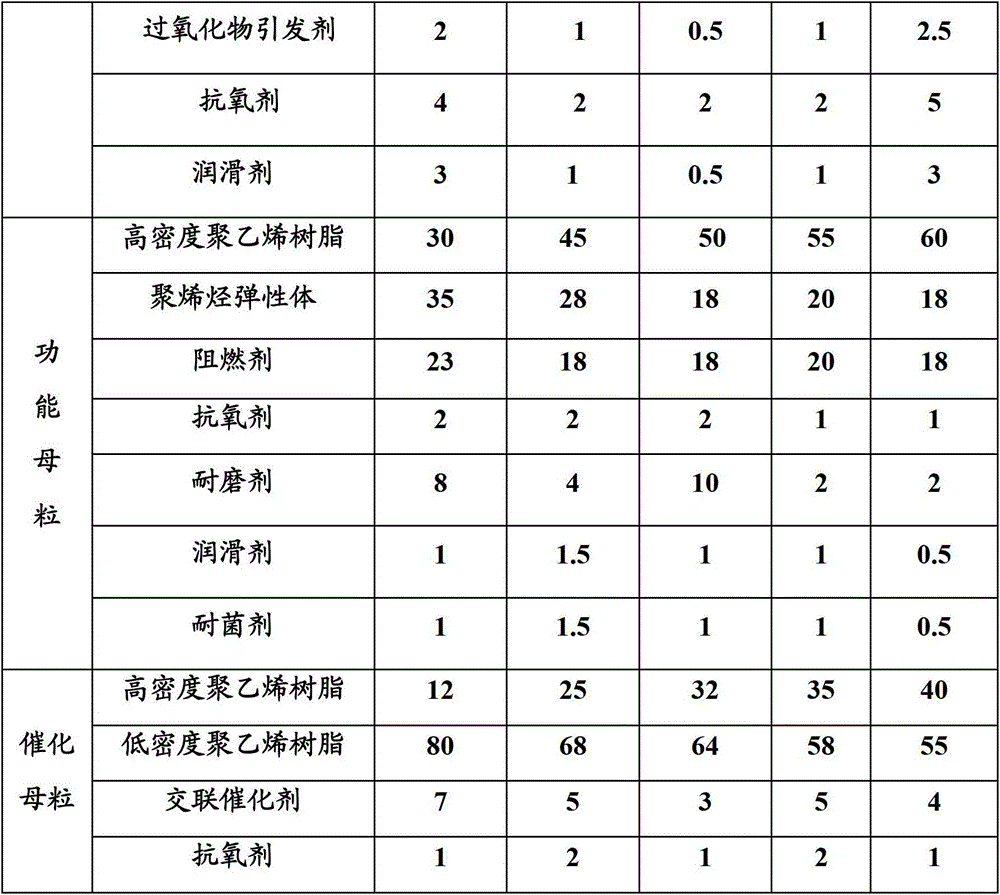

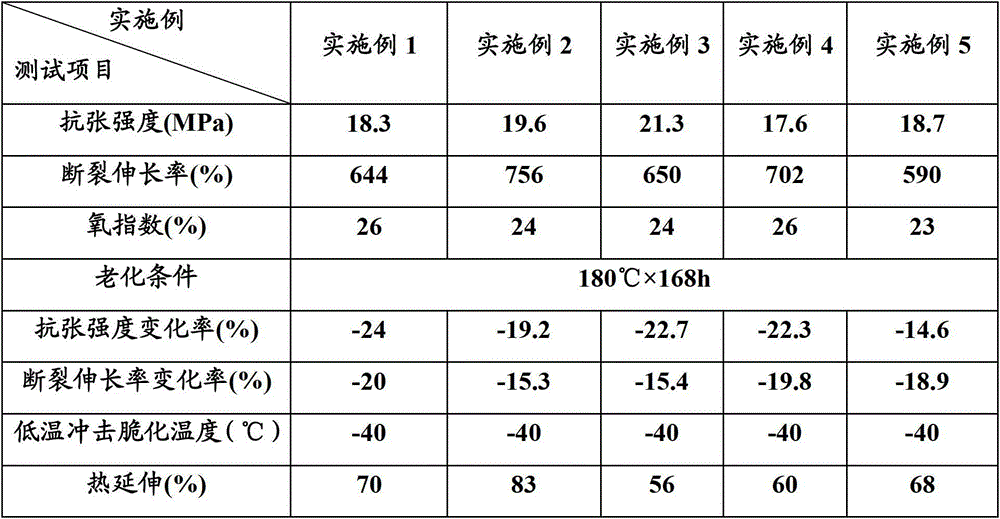

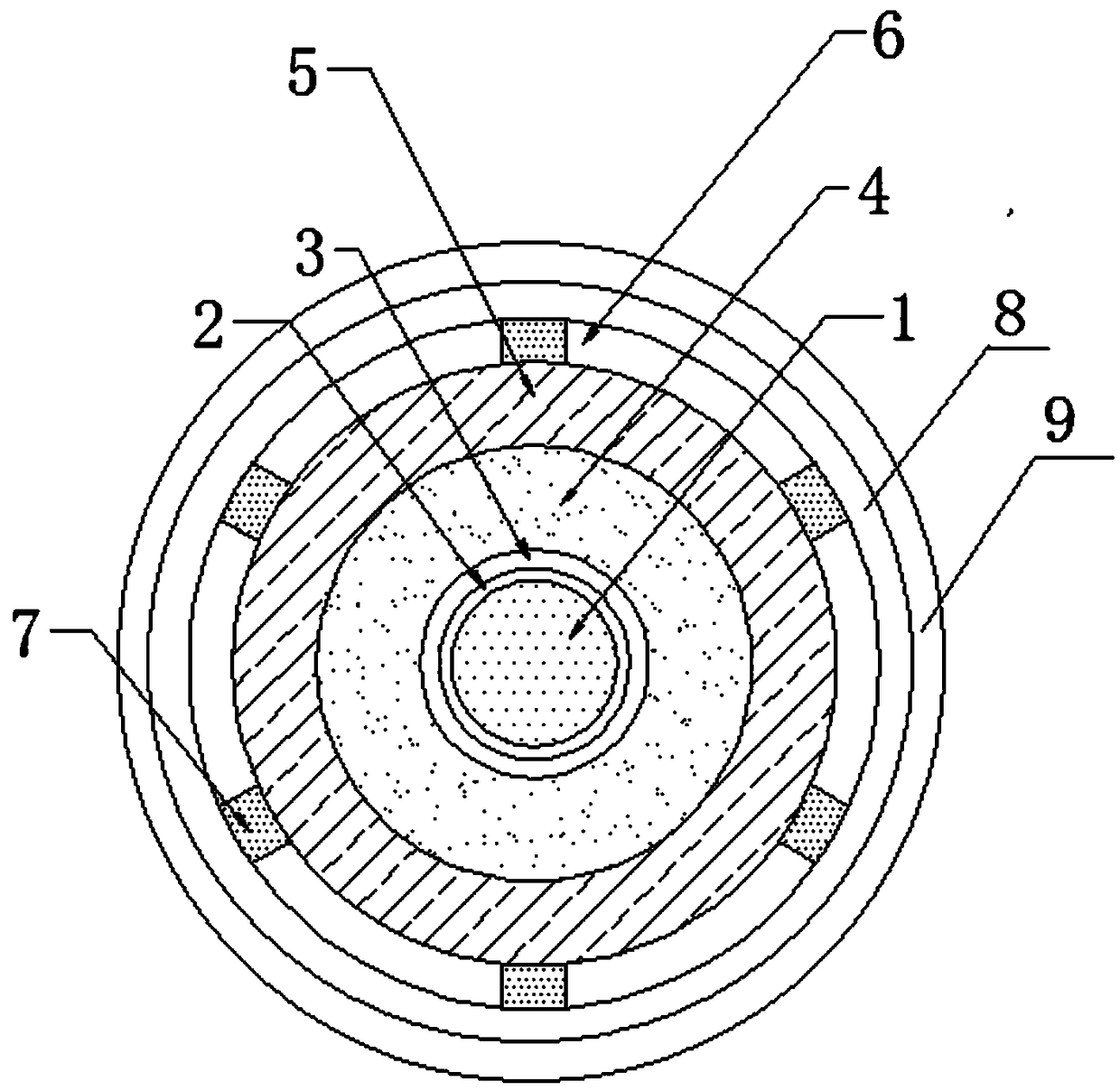

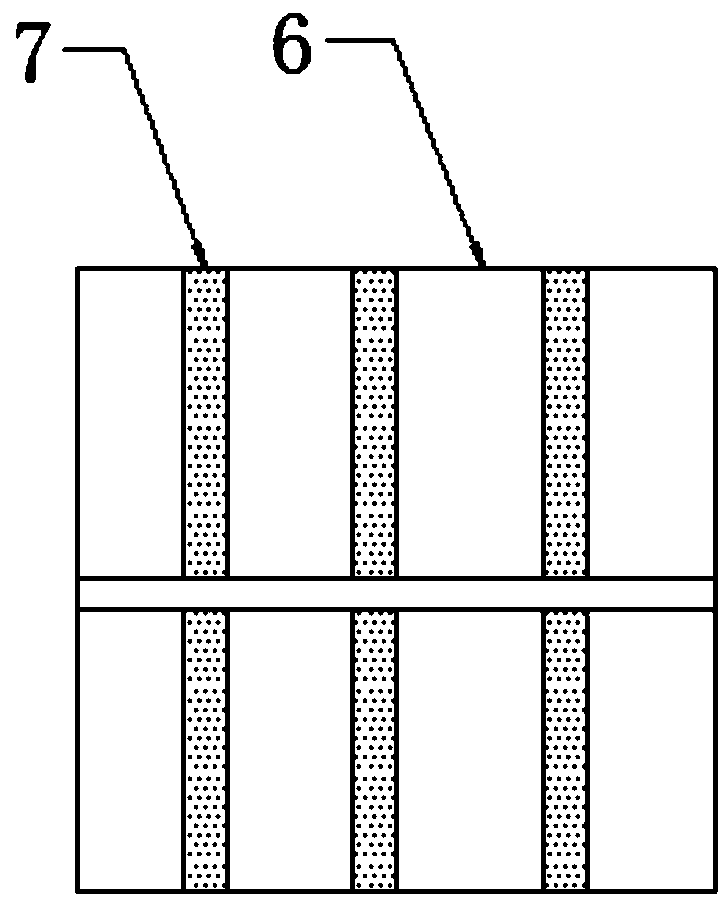

The invention relates to a high-temperature-resistant silane-crosslinked flame-retardation insulating material for automobile wires. The material comprises basic master batches, functional master batches and catalysis master batches with a weight ratio of 100 : 25-40 : 5-10, wherein the basic master batches comprise high-density polyethylene resin, polyester elastomer, hydrogenated nitrile rubber, maleic anhydride monomer, a silane cross-linking agent, a peroxide initiator, an anti-oxidant and a lubricant; the functional master batches comprise the high-density polyethylene resin, the polyester elastomer, a fire retardant, a wear-resistant agent, a lubricant and a bacteria-resistant agent; and the catalysis master batches comprise the high-density polyethylene resin, low-density polyethylene resin, a crosslinking catalyst and the anti-oxidant. The high-temperature-resistant silane-crosslinked flame-retardation insulating material meets requirements of T3 and T4 standards of DINISO6722 T1 to T4, can be used as novel materials for the automobile wires, and is free of irradiation and low in technology cost.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

Wear resistant type plastic floor and its production technology

ActiveCN1903926AGood mechanical propertiesExcellent weather and corrosion resistanceFlat articlesSpecific gravityWear resistant

The present invention relates to an abrasion-resistant plastic floor board and its production process. Said process includes the following steps: using waste and old plastic powder as main raw material, adding active calcium carbonate and plastic filling agent as auxiliary raw material, mixing them and extruding them to obtain plastic foamed granules, die-pressing and forming, cooling, setting, drawing and cutting so as to obtain the invented plastic base plate, then sticking plastic protection film on its surface, so that the invented plastic floor board finished product can be made up.

Owner:无锡市中德装饰新材料有限公司

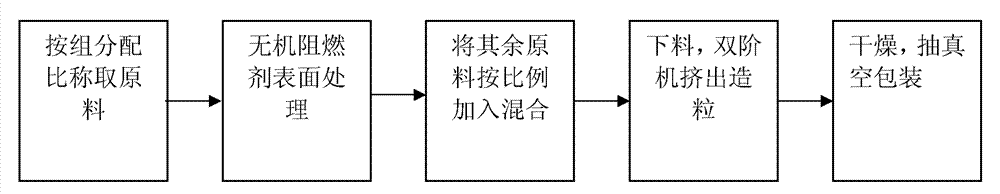

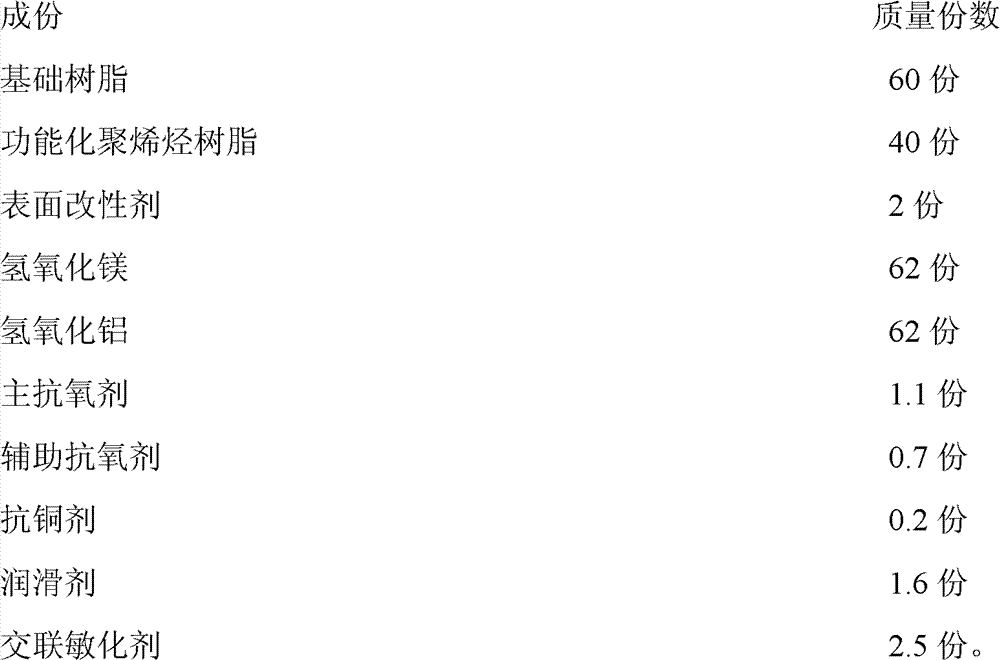

150DEG C irradiation crosslinking low-smoke halogen-free flame retardant polyolefin material for locomotive wires and its preparation

ActiveCN102898716AHigh temperature resistanceGood oil resistancePlastic/resin/waxes insulatorsAntioxidantHigh polymer

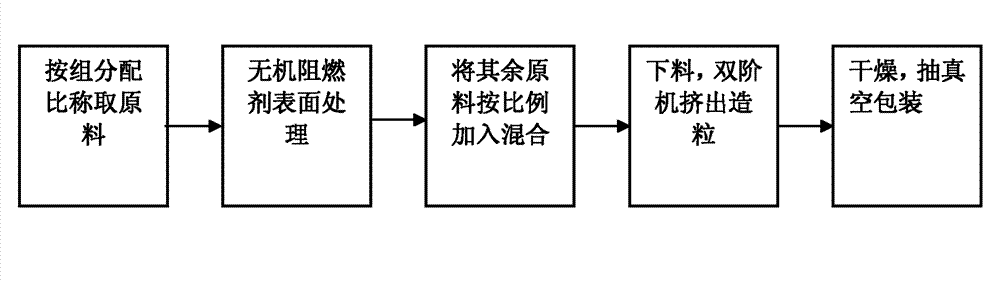

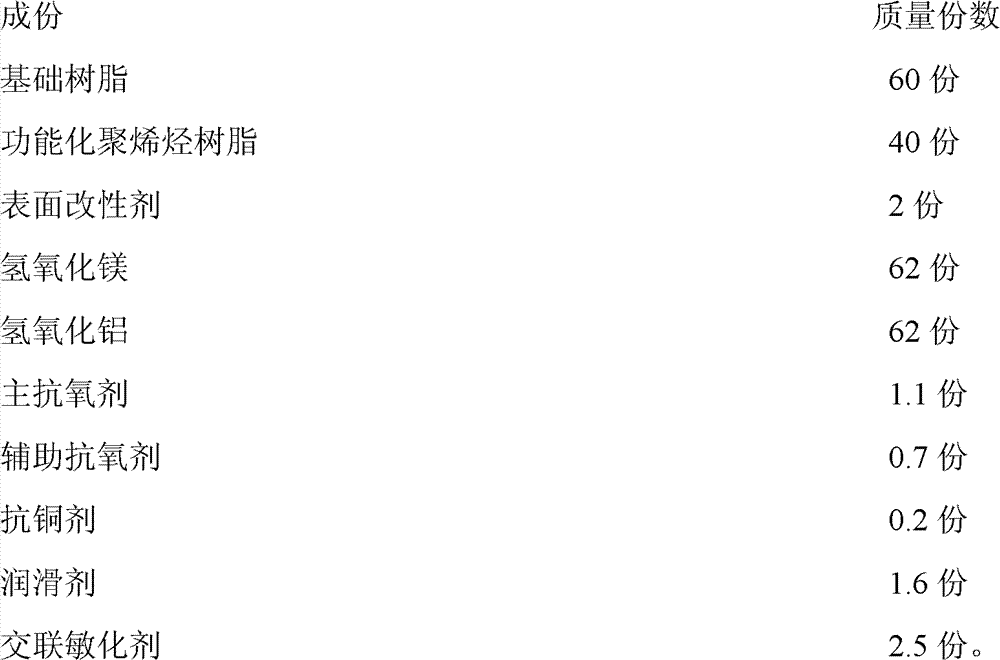

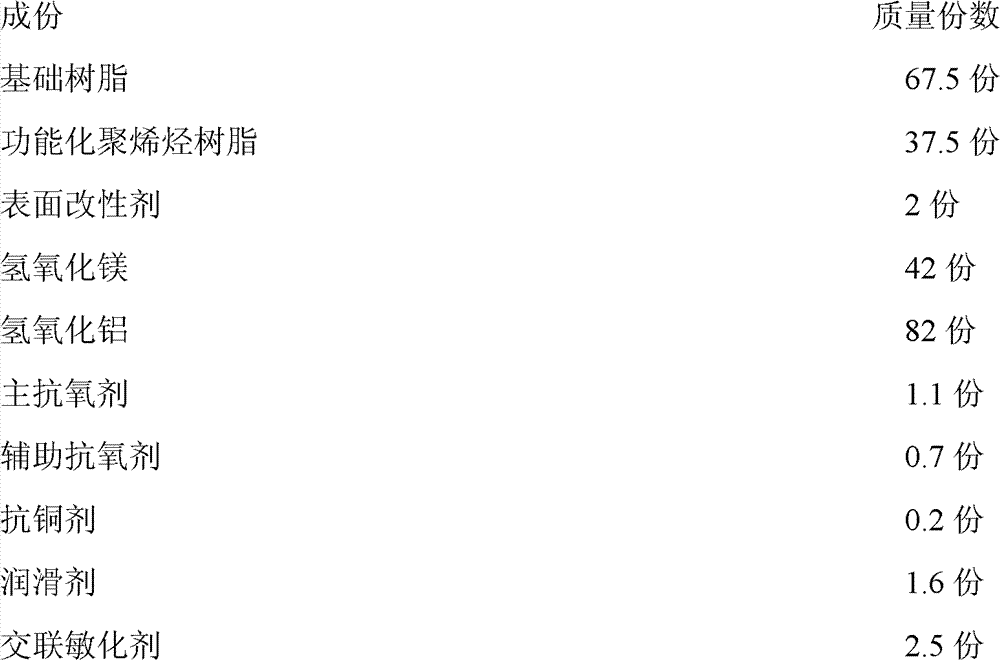

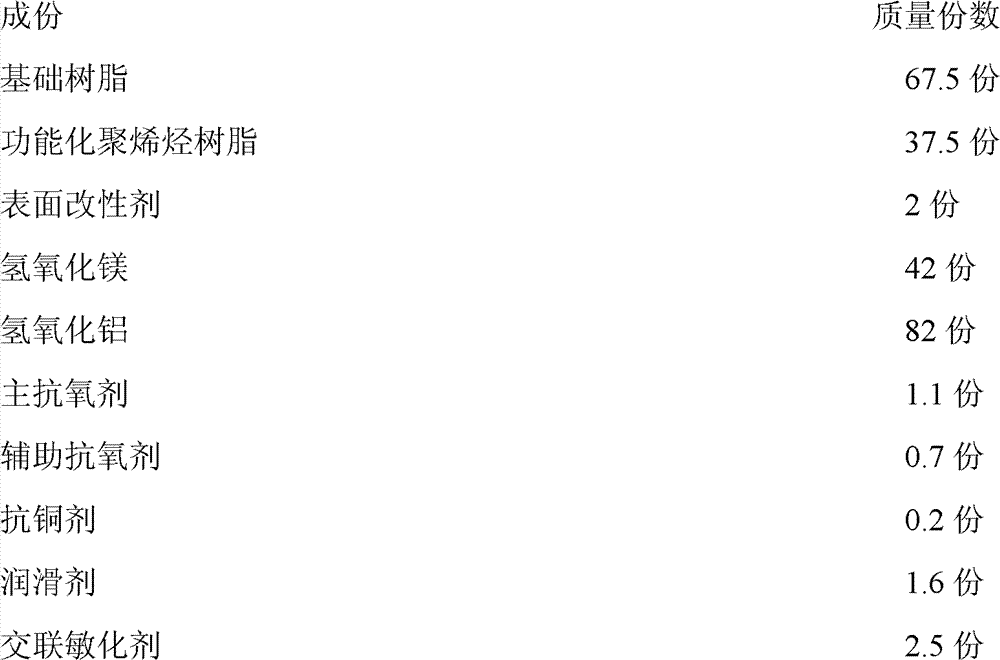

Belonging to high polymer materials for electric wires and cables, the invention relates to a 150DEG C irradiation crosslinking low-smoke halogen-free flame retardant polyolefin material for locomotive wires and its preparation. The 150DEG C irradiation crosslinking low-smoke halogen-free flame retardant polyolefin material for locomotive wires provided in the invention comprises base resin, functionalized polyolefin resin, a halogen-free flame retardant, a surface modifier, a main antioxidant, auxiliary antioxidants, an anti-copper agent, a lubricating agent and a crosslinked sensitizer. The 150DEG C irradiation crosslinking low-smoke halogen-free flame retardant polyolefin material for locomotive wires has the advantages of high temperature resistance grade, good oil-proofness, relatively low cost, no halogen in the whole system, low smoke during combustion and the like, it also has excellent extrusion process performance. Cables extruded from the low-smoke halogen-free flame retardant polyolefin material can completely meet the requirements of 150DEG C cables for locomotive wires.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

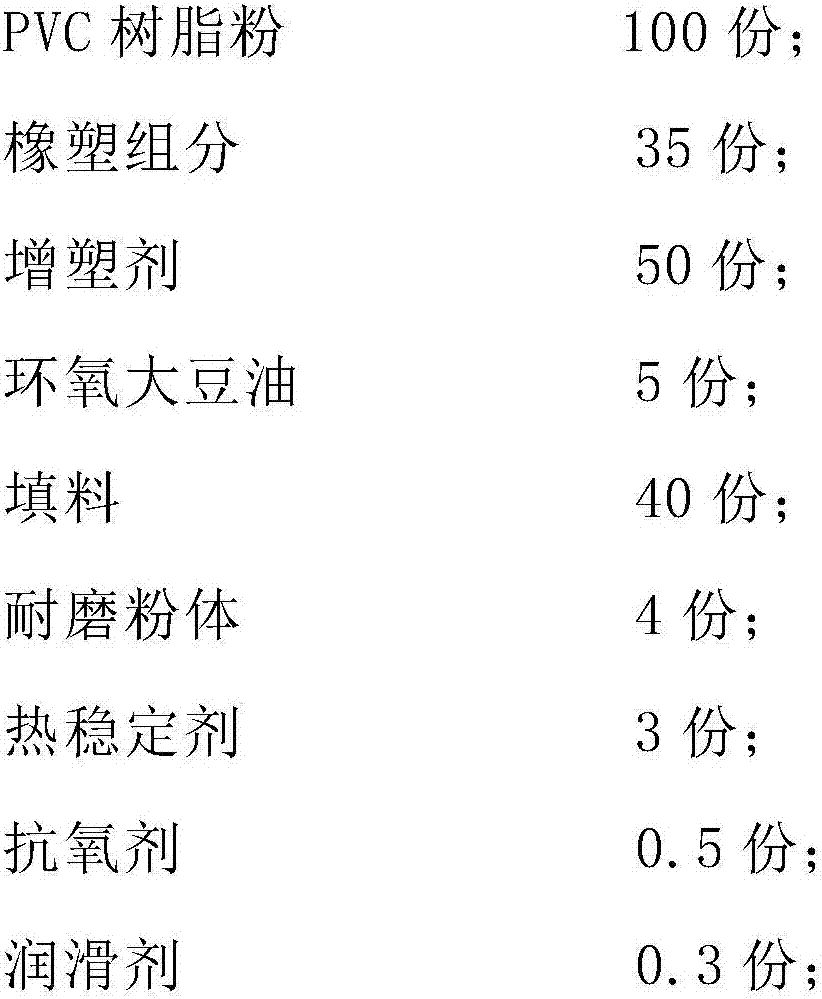

Wear-resistant and oil-proof PVC elevator cable material and preparation method thereof

InactiveCN107057227AMeet the requirements of wear resistance and oil resistanceSimple extrusion processPlastic/resin/waxes insulatorsPlasticizerWear resistant

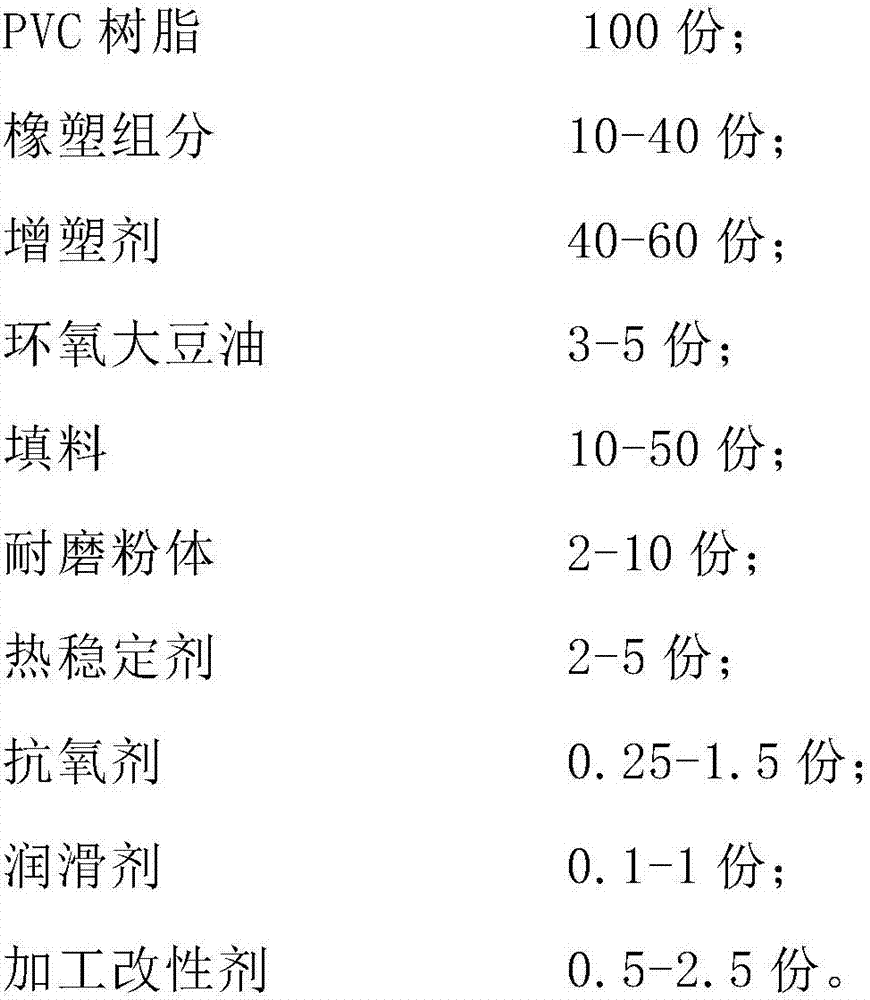

The invention discloses a wear-resistant and oil-proof PVC elevator cable material. The wear-resistant and oil-proof PVC elevator cable material consists of the following raw materials in parts by weight: polyvinyl chloride resin 100 parts, a rubber and plastic component 10-40 parts, a plasticizer 40-60 parts, epoxy soybean oil 3-5 parts, a filler 10-50 parts, wear-resistant powder 2-10 parts, a thermal stabilizer 2-5 parts, an oxidation inhibitor 0.25-1.5 parts, a lubricant 0.1-1 part, and a modifier 0.5-2.5 parts. The invention further discloses a preparation method of the wear-resistant and oil-proof PVC elevator cable material. The preparation method comprises the following steps: first step, preparing raw materials, and accurately weighing various materials proportionally; second step, mixing the materials uniformly and carrying out preplasticizing; third step, extruding, mixing and pelleting by a double-stage double-screw extruder, wherein the temperature range of the extruder is 140-175 DEG C; fourth step, cooling, sieving and carrying out magnetic separation; and fifth step, packing and storing.

Owner:上海贝恩科电缆有限公司

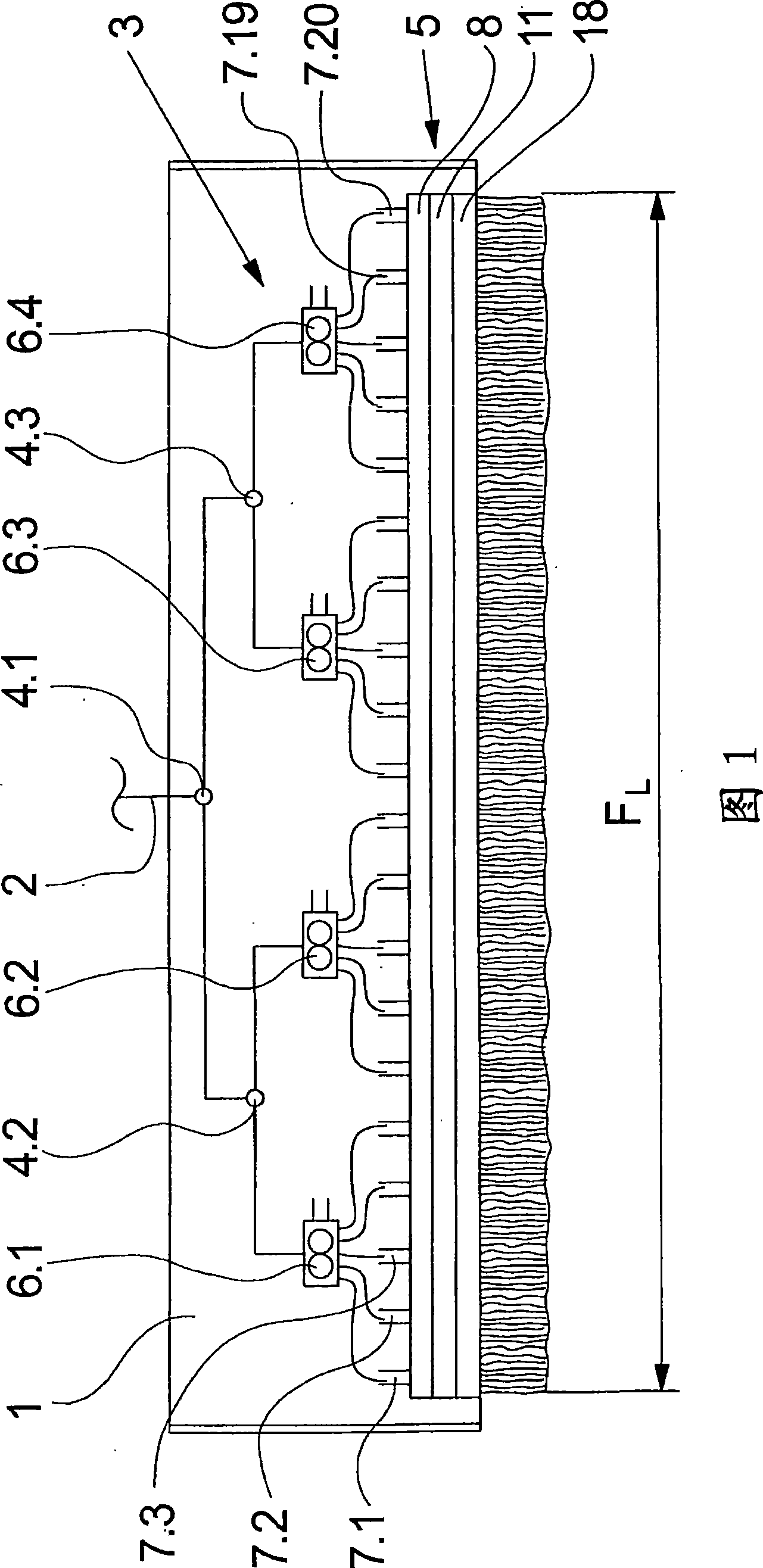

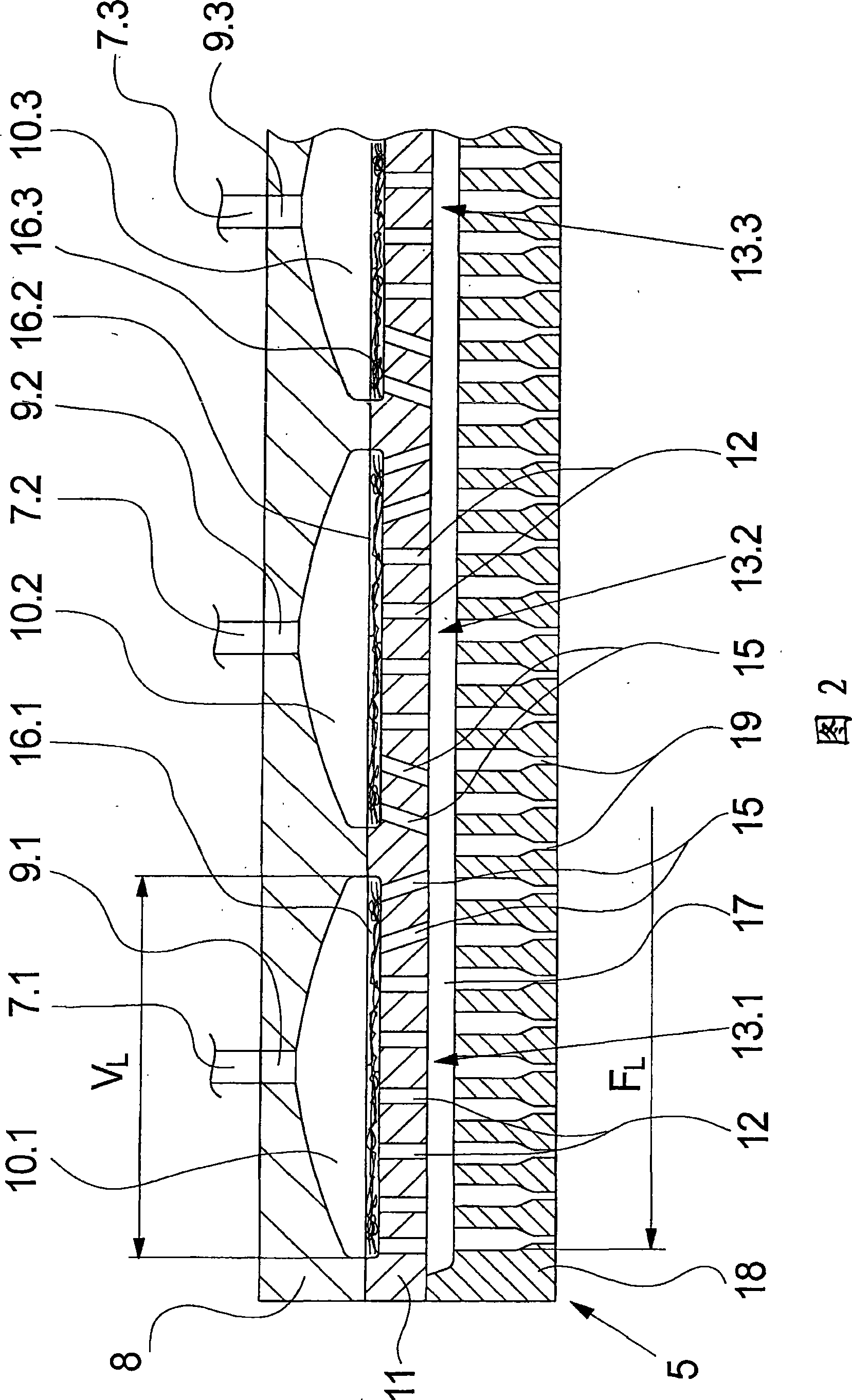

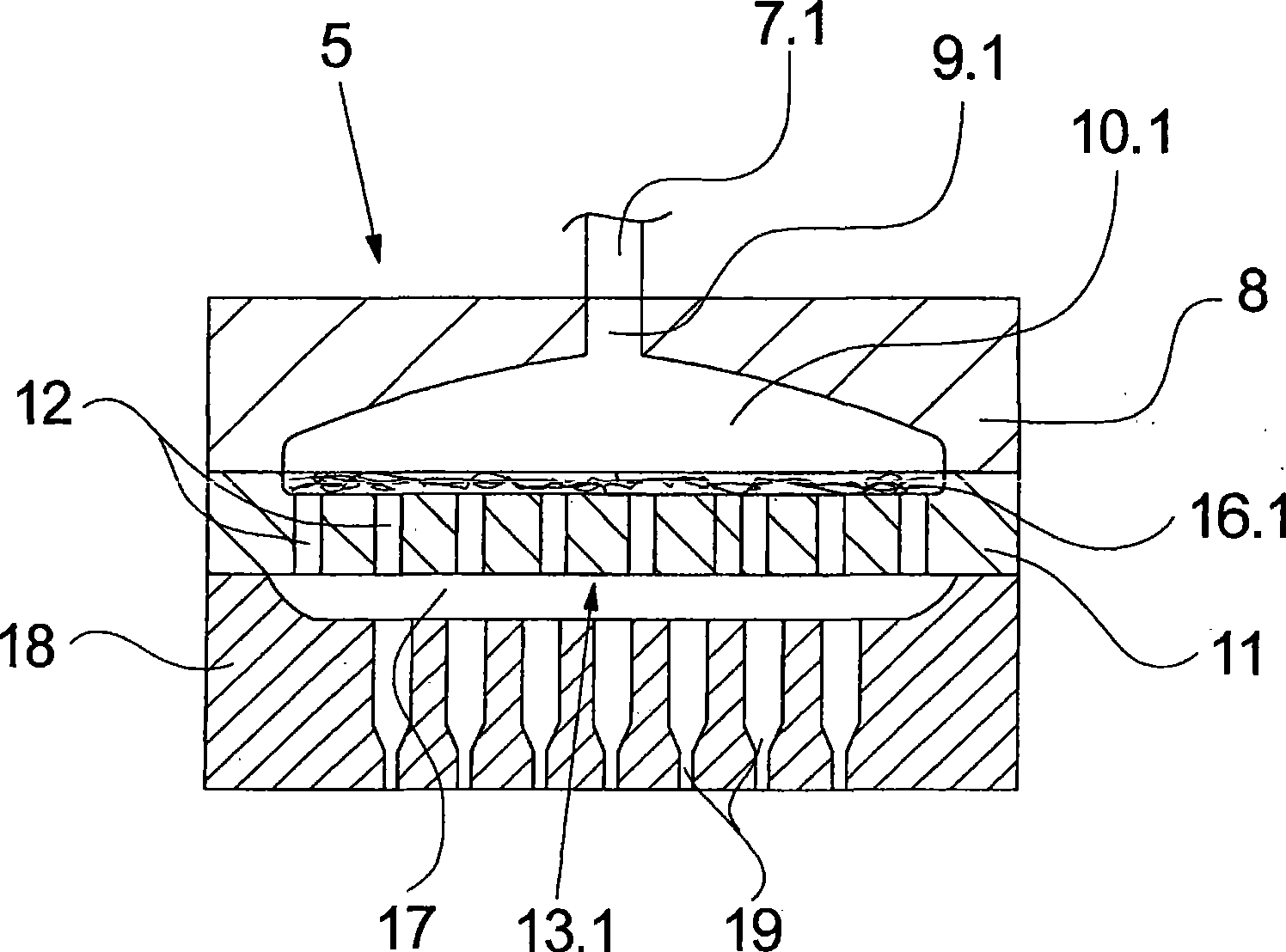

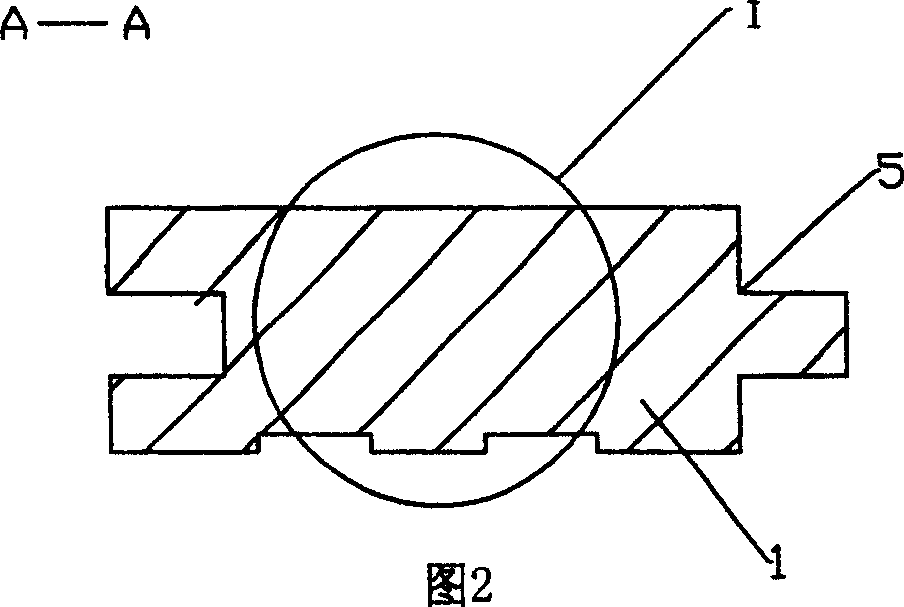

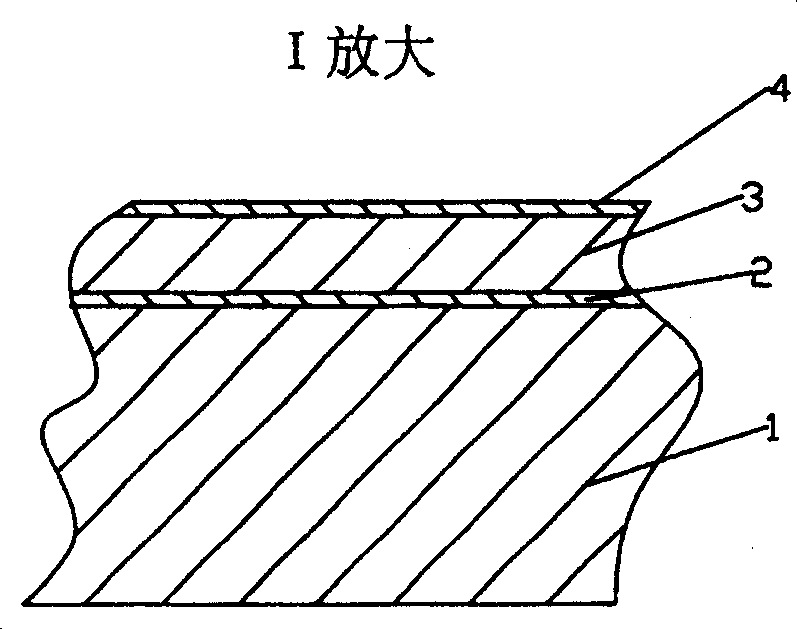

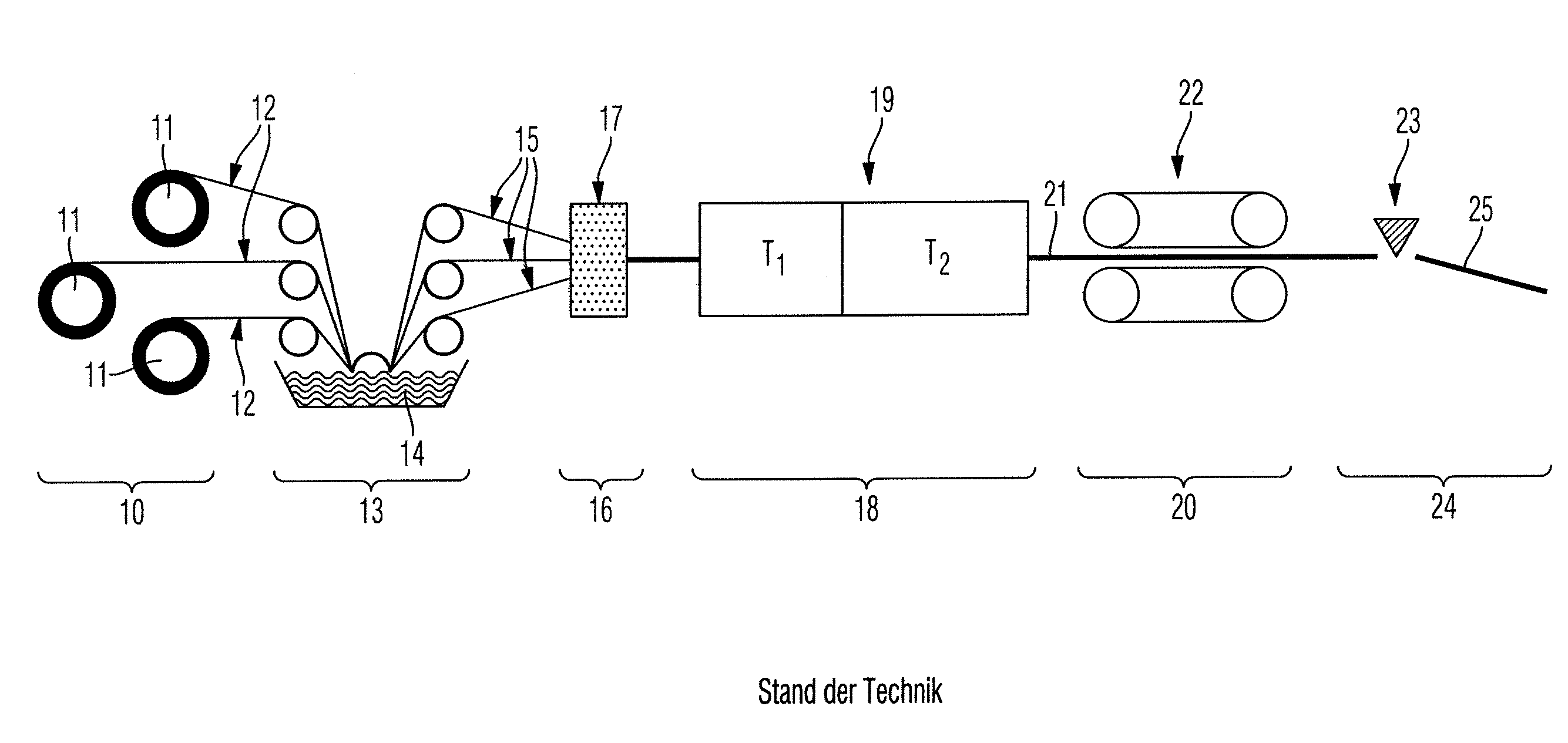

Device for melt spinning of a linear filament bundle

ActiveCN101443489AEvenly distributedConstant dwell timeSpinnerette packsMelt spinning methodsPolymer meltMelt spinning

The invention relates to a device for melt spinning of a linear filament bundle with a spinning beam for mounting a longitudinal spinning nozzle group. The spinning nozzle group comprises a nozzle plate on an underside with a number of nozzle drillings and an inlet plate on an upper side with at least one inlet channel, a distribution chamber being arranged between the inlet plate and the nozzle plate, connected to the inlet channel in the inlet plate and the nozzle drillings in the nozzle plate. According to the invention, a residence time for the polymer melt within the nozzle group is kept as constant as possible with a large production range by means of the inlet plate having several residence chambers connected to inlet channels, arranged at a separation from each other in the longitudinal direction of the spinning beam.

Owner:OERLIKON TEXTILE GMBH & CO KG

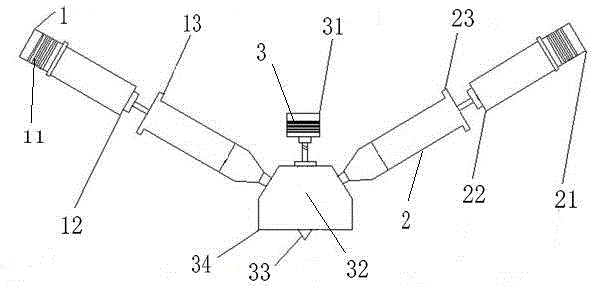

3D printing material based on fused deposition manufacturing process, printing method and printing device

ActiveCN105086347ALow priceNo pollution in the processAdditive manufacturing apparatusEngineeringPollution

The invention discloses a 3D printing material based on a fused deposition manufacturing process, a printing method and a printing device. The 3D printing material is composed of a basic material and a curing agent. The printing method includes that a principle that A-stage phenolic resin can realize quick crosslinking and curing under a certain acidic condition, mixing curing and deposition modeling are performed at a position needing modeling, and products different in performance can be produced through different proportions. The printing device is composed of a first material barrel device, a second material barrel device and a nozzle device, the lower end of the first material barrel device and that of the second material barrel device are fixed on the nozzle device respectively, and the first material barrel device and the second material barrel device are completely identical in structure. Raw materials are low in cost, easy to obtain, environment friendly and free of pollution and damage to human body, the 3D printing material is simple to manufacture and easy in operation, the printing device is simple, convenient to operate and maintain, low in maintenance cost, simple in material extruding process, supportive of low-temperature modeling and suitable for wide application.

Owner:JILIN UNIV

Method for producing wear resistant type plastic floor

ActiveCN100462398CImprove wear resistanceStrong fire resistanceFlat articlesTectorial membraneAdhesive

The present invention relates to an abrasion-resistant plastic floor board and its production process. Said process includes the following steps: using waste and old plastic powder as main raw material, adding active calcium carbonate and plastic filling agent as auxiliary raw material, mixing them and extruding them to obtain plastic foamed granules, die-pressing and forming, cooling, setting, drawing and cutting so as to obtain the invented plastic base plate, then sticking plastic protection film on its surface, so that the invented plastic floor board finished product can be made up.

Owner:无锡市中德装饰新材料有限公司

105℃ irradiation cross-linked low-smoke halogen-free flame retardant polyolefin sheath material for locomotive thin-walled wire and its preparation and application

ActiveCN102295794ARich sourcesFair priceInsulated cablesInsulated conductorsMaterials preparationPolyolefin

The invention relates to a 150 DGE C irradiation crosslinking low-smoke halogen-free antiflaming polyolefin sheathing compound for a locomotive thin-walled line. The sheathing compound is prepared from the following raw material components in parts by weight: 60-90 parts of substrate, 10-40 parts of compatilizer, 50-100 parts of halogen-free flame retardant, 5-30 parts of halogen-free antiflamingauxiliary, 2-4 parts of antioxidant, 0.5-2 parts of lubricant, 1-4 parts of crosslinking sensitizing agent and 1-5 parts of powder dispersing agent. The 150 DGE C irradiation crosslinking low-smoke halogen-free antiflaming polyolefin sheathing compound has the advantages that the cost is relatively low, the whole system dose not contain halogen, and the sheathing compound has scraping resistance,oil resistance, low fuming amount in burning and the like and completely meets the requirement of a cable for the 150 DGE C locomotive thin-walled line.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

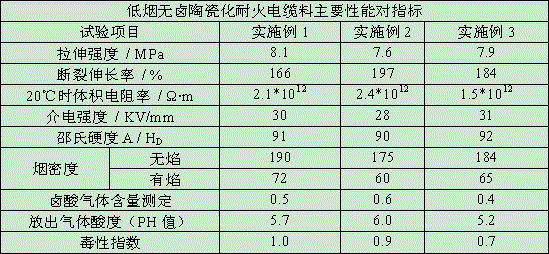

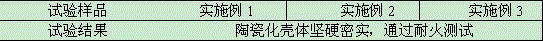

Low-smoke zero-halogen ceramic fireproof cable material and preparation method thereof

InactiveCN105131416ACrust temperature is lowReduced insulation effectPlastic/resin/waxes insulatorsOcteneCarvacryl acetate

The invention relates to a low-smoke zero-halogen ceramic fireproof cable material and a preparation method thereof. The low-smoke zero-halogen ceramic fireproof cable material is prepared from the following materials in parts by weight: an ethylene-vinyl acetate copolymer, an ethylene-alpha-olefin copolymer, maleic anhydride-grafted amorphous polyolefin, mica powder, ceramic powder, glass powder, magnesium hydroxide, calcium oxide, zinc oxide, melamine cyanurate, an antioxidant 1010, a silane coupling agent A-172, and lubricant silicone master batch; the ethylene content of the ethylene-vinyl acetate copolymer is 28-40%, and the melt flow rate is 3-5g / 10min; the ethylene-alpha-olefin copolymer is a mixture of one or two of an ethylene-alpha-propylene copolymer and an ethylene-alpha-octene copolymer which are mixed according to any ratio by weight; the glass powder is low-melting-point glass powder having the melting point of 500-800 DEG C. The low-smoke zero-halogen ceramic fireproof cable material is porcelainized to change into a hard ceramic protection layer after ignition at high temperature and has certain mechanical strength, thereby ensuring normal operation of a wire and cable line.

Owner:中广核三角洲(苏州)高聚物有限公司

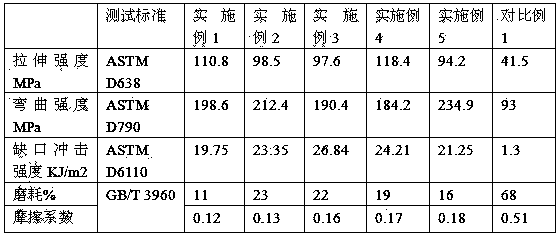

Wear-resistant nylon composite material and preparation method therefor

The invention discloses a wear-resistant nylon composite material. The wear-resistant nylon composite material is prepared from the following ingredients in parts by weight: 65-95 parts of high-temperature resistant nylon, 1-15 parts of pretreated molybdenum disulfide, 0.1-1.0 part of antioxidant and 0.2-1.0 part of lubricant. The invention also discloses a preparation method for the wear-resistant nylon composite material. According to the wear-resistant nylon composite material and the preparation method therefor, the pretreated molybdenum disulfide is added as a wear resistance modifier, and proper processing aids are added, so that the wear resistance and heat resistance of high-temperature nylon are improved, the use value is higher, the field of employment is widened, and the wear-resistant nylon composite material can be extensively applied to the fields of electronic electrical appliances, automobiles, war industry and the like; the composite material disclosed by the invention is simple in extruded preparation process, high in continuous production efficiency and stable in product quality; and the high-temperature nylon and the pretreated molybdenum disulfide are pre-mixed firstly, so that the dispersity of the pretreated molybdenum disulfide in the composite material is greatly improved, and the wear resistance of the composite material is improved.

Owner:HEFEI GENIUS NEW MATERIALS

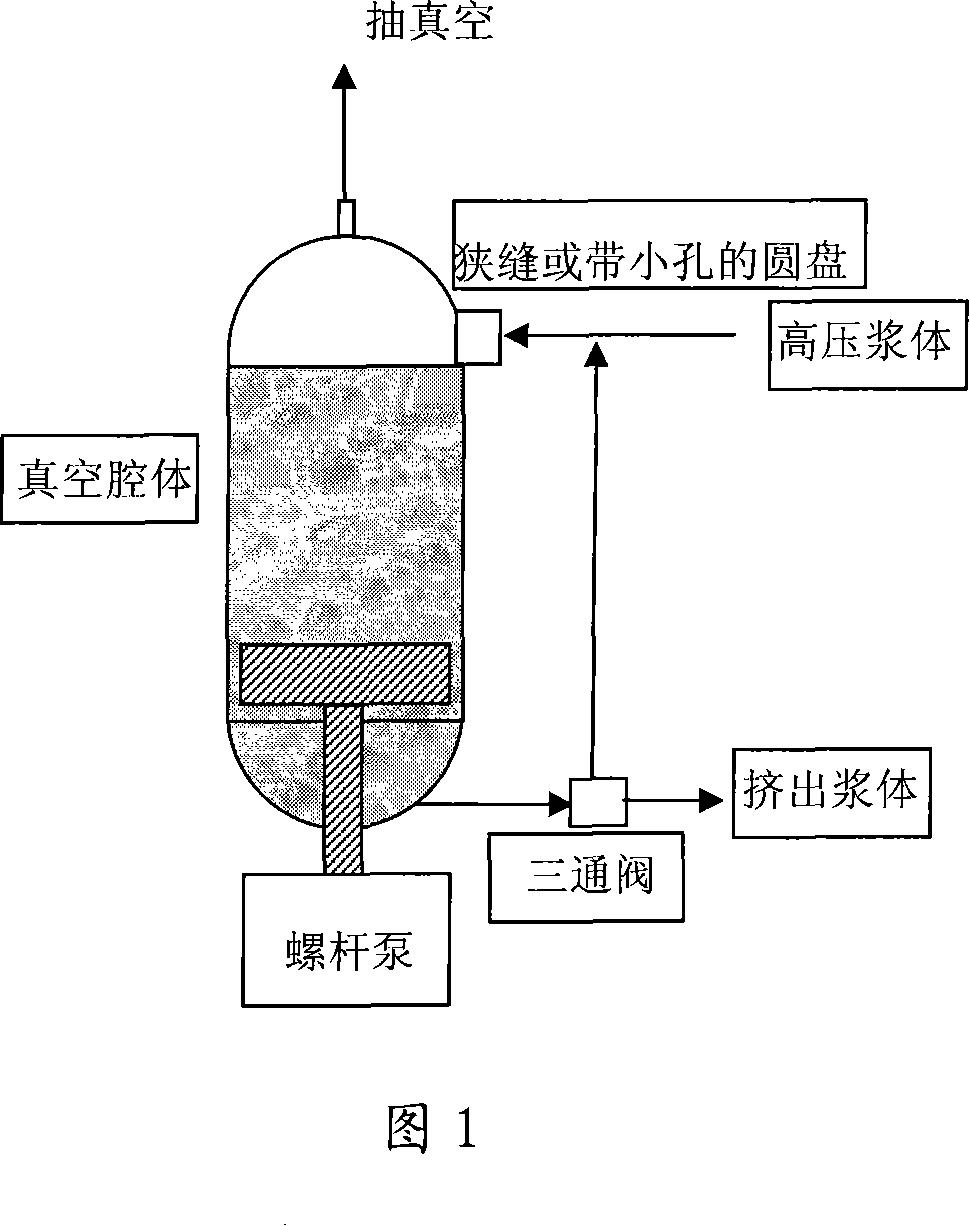

Slurry extruding method of disposable tableware produced by magnesia oxychloride cement

InactiveCN101148063ASimple extrusion processExtrusion slurry time can be controlledCeramic shaping apparatusCircular discCement slurry

The present invention relates to process of mixing and extruding magnesium oxychloride cement slurry for producing disposable tableware. The process includes raising the pressure of magnesium oxychloride cement slurry to 0.5-10 MPa, extruding the slurry through one disc with one slit or small hole into one cavity, vacuumizing the cavity from the top to 0.1-0.04 MPa, extruding magnesium oxychloride cement slurry out of the cavity with one screw pump mounted in the bottom of the cavity and controlling the extruded slurry amount with one three-way valve in the outlet of the screw pump. The present invention has simple slurry extruding process, controllable extrusion time, no bubble in the extruded slurry and other advantages.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

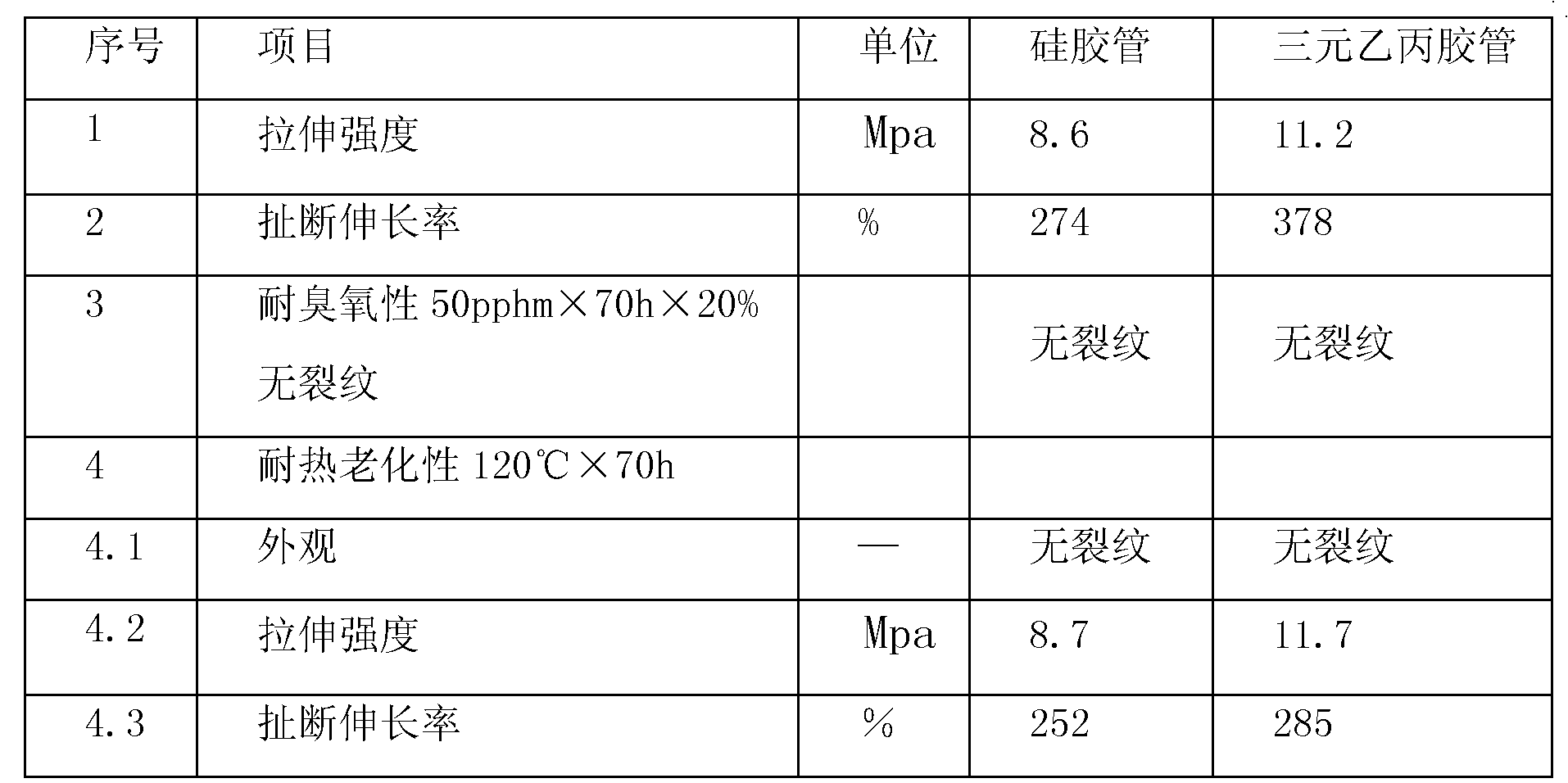

Ethylene propylene diene rubber composition for air outlet pipe of intercooler and preparation method thereof

InactiveCN102627809AExcellent extrusion performanceGood heat aging resistanceFlexible pipesIntercoolerCoumarones

The invention relates to an ethylene propylene diene rubber for an air outlet pipe of an intercooler. The rubber composition consists of ethylene propylene diene rubber, zinc oxide, polyethylene glycol, an anti-ageing agent RD, coumarone, carbon black, paraffin oil, an accelerating agent and sulfur. A preparation method of the rubber composition comprises the following steps of: selecting a rubber extruder, controlling the length-diameter ratio of a screw rod at 11-15, and controlling the temperature at each stage of the extruder, wherein the temperature of a handpiece is 60-80 DEG C, the temperature of an extruding section is 50-70 DEG C, the temperature of a plasticizing section is 50-70 DEG C, and the temperature of a feeding section is 50-60 DEG C; controlling the temperature of circulating water at 15+ / -5 DEG C, cooling and sizing a rubber pipe, cutting length, and standing for later use; and sleeving a semi-finished product on a mandrel of a fixed specification, and entering a steam vulcanizing tank for vulcanizing at the vulcanizing temperature of 150-170 DEG C for 15-40 minutes. An air outlet rubber pipe of the intercooler processed by using gross rubber produced with the method has the advantages of low price, appropriate performance, simple production process, high efficiency, excellent ageing resistance and high ozone resistance, and better meets the current use requirements.

Owner:TIANJIN PENGYI GRP CO LTD

Wear-resistant and high-temperature-resistant nylon composite material and preparation method thereof

The invention provides a wear-resistant and high-temperature-resistant nylon composite material and a preparation method thereof. The composite material comprises the following components in parts by weight: 65-95 parts of high-temperature-resistant nylon, 5-35 parts of nylon66, 1-15 parts of wear-resistant agent, 0.1-1.0 part of antioxidant and 0.2-1.0 part of lubricating agent, and is prepared by virtue of a double-screw melt blending extrusion process after mixing. According to the wear-resistant and high-temperature-resistant nylon composite material, nylon66 and the wear-resistant agent are firstly premixed so as to greatly improve the dispersibility of the wear-resistant agent in the composite material and regulate the viscosity of the composite material, thus improving the wear-resistance performance and heat-resistant performance of the composite material, ensuring that the composite material has higher application values, and broadening the application range; the composite material can be widely applied to the field of electronic and electrical appliances, automobiles, military industries and the like, and can be used for promoting the smooth processing of extruding machines.

Owner:HEFEI GENIUS NEW MATERIALS

Fire-resistant and high-temperature-resistant control cable and manufacturing method thereof

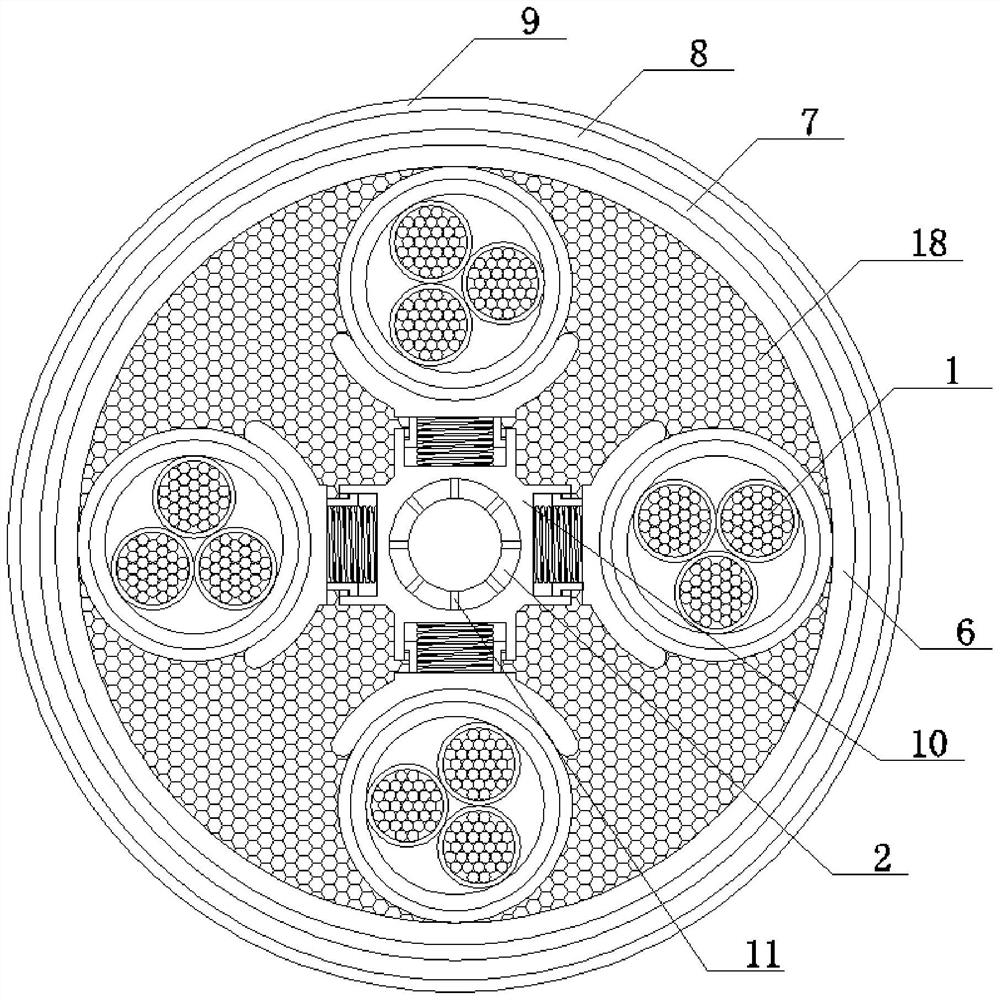

ActiveCN111799029AAnti aging catalysisGuaranteed service lifeClimate change adaptationInsulated cablesEngineeringElectrical conductor

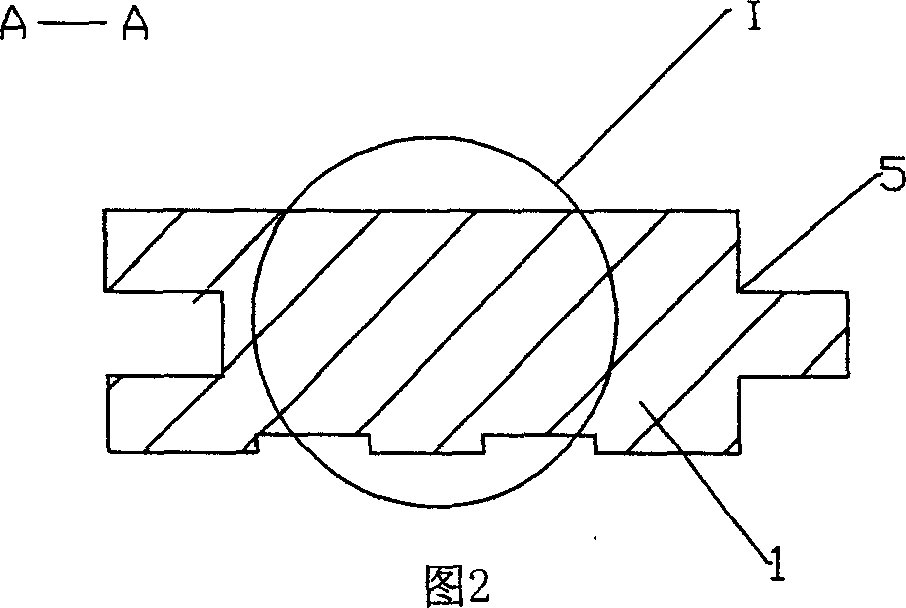

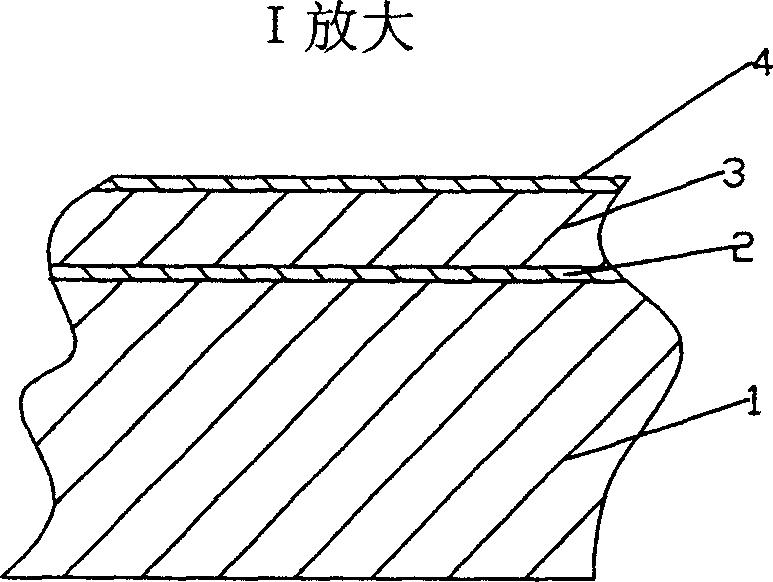

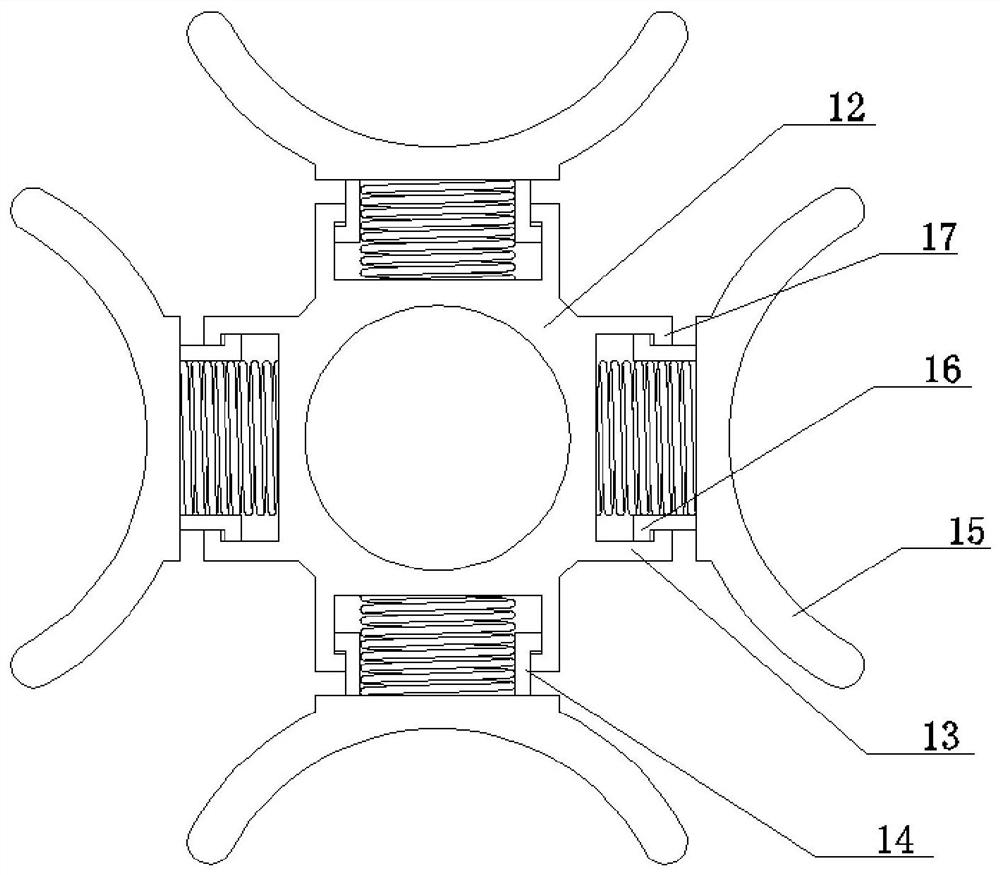

The invention discloses a fire-resistant and high-temperature-resistant control cable including multiple sets of conductors and including a heat dissipation reinforcing tube, wherein the conductors are coated with insulating layers to form insulating wire cores; the plurality of insulating wire cores are coated with braided shielding layers, the braided shielding layers are coated with high-temperature-resistant loose tubes to form main wire cores, the plurality of main wire cores are combined and are sequentially coated with a fireproof heat-insulating layer, a flame-retardant inner sheath, abraided armor layer and a flame-retardant outer sheath, the heat dissipation reinforcing pipe is located among the plurality of main wire cores, a plurality of support frames are fixedly connected tothe heat dissipation reinforcing pipe at equal intervals, and the fireproof heat-insulating layer is also filled with heat-insulating flame-retardant particles; the heat dissipation reinforcing pipemade of polytetrafluoroethylene is arranged among the main wire cores, the appearance organization is fine, no mechanical impurity exists, the strength is high, the heat dissipation reinforcing tube are located in the center gap of the main wire cores, and the structural stability, the tensile property and the high temperature resistance of the cable are improved. And through a plurality of vent holes in the surface of the heat dissipation reinforcing pipe, a heat dissipation effect can be achieved, and the internal heat resistance of the cable is improved.

Owner:TIANCHANG HUILING ELECTRIC APPLIANCE METER FACTORY

Wear-resistant and high-temperature resistant nylon composite material and preparation method therefor

The invention discloses a wear-resistant and high-temperature resistant nylon composite material. The wear-resistant and high-temperature resistant nylon composite material is prepared from the following ingredients in parts by weight: 65-95 parts of high-temperature resistant nylon, 1-15 parts of pretreated molybdenum disulfide, 0.1-1.0 part of antioxidant and 0.2-1.0 part of lubricant. The invention also discloses a preparation method for the wear-resistant and high-temperature resistant nylon composite material. According to the wear-resistant and high-temperature resistant nylon composite material and the preparation method therefor, the pretreated molybdenum disulfide is added as a wear resistance modifier, and proper processing aids are added, so that the wear resistance and heat resistance of high-temperature nylon are improved, the use value is higher, the field of employment is widened, and the wear-resistant and high-temperature resistant nylon composite material can be extensively applied to the fields of electronic electrical appliances, automobiles, war industry and the like; the composite material disclosed by the invention is simple in extruded preparation process, high in continuous production efficiency and stable in product quality; and the high-temperature nylon and the pretreated molybdenum disulfide are pre-mixed firstly, so that the dispersity of the pretreated molybdenum disulfide in the composite material is greatly improved, and the wear resistance of the composite material is improved.

Owner:HEFEI GENIUS NEW MATERIALS

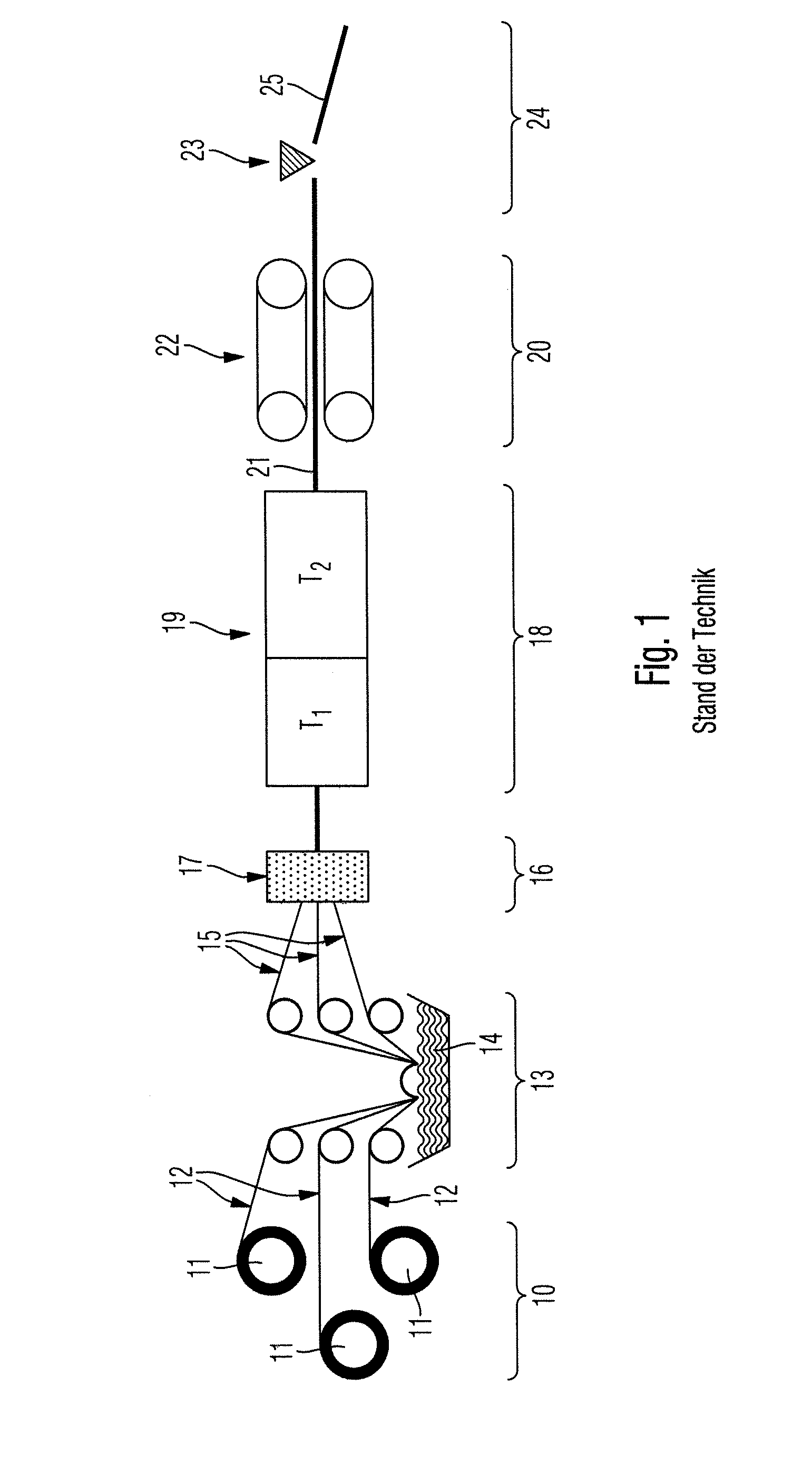

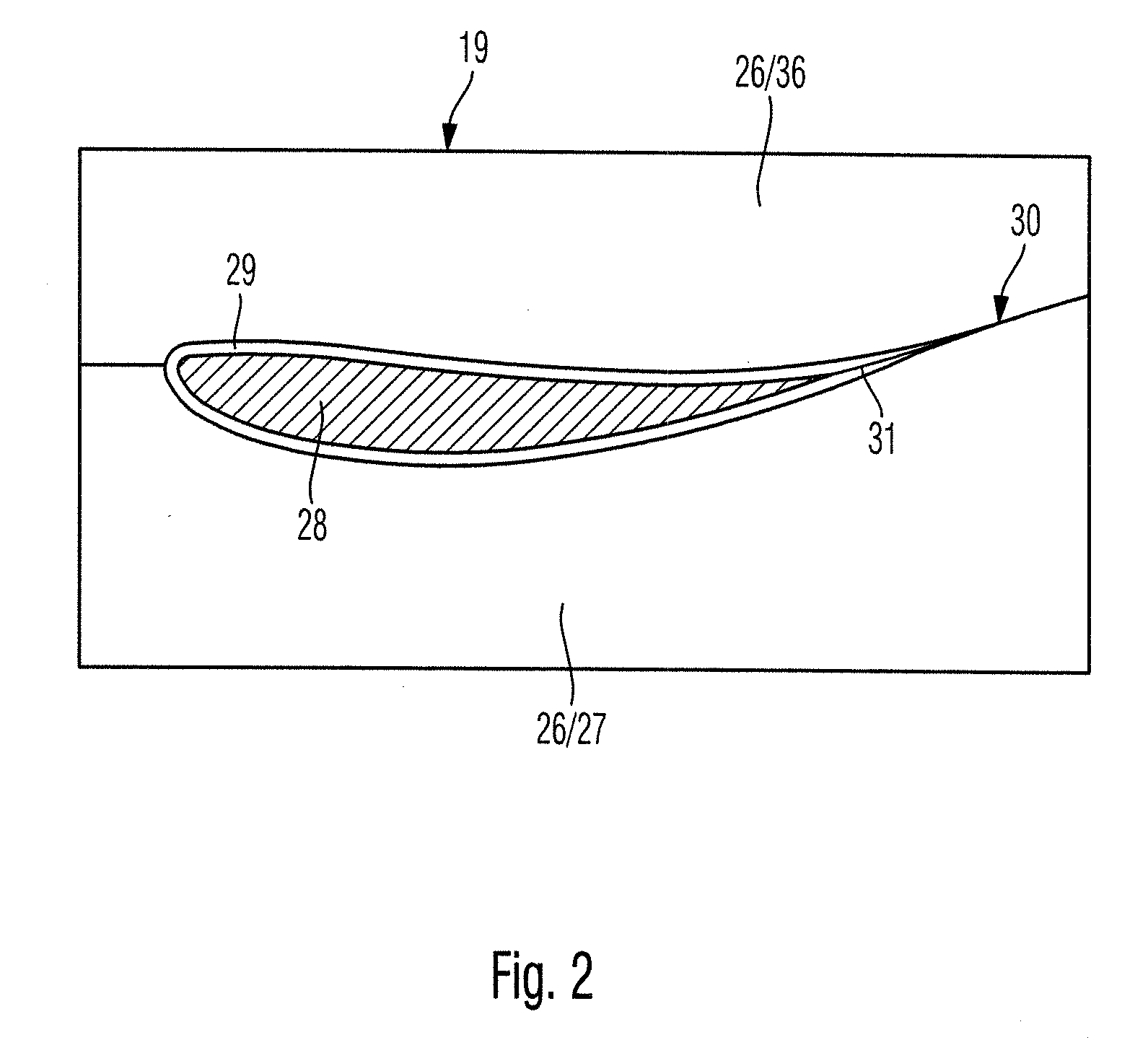

Process for producing components

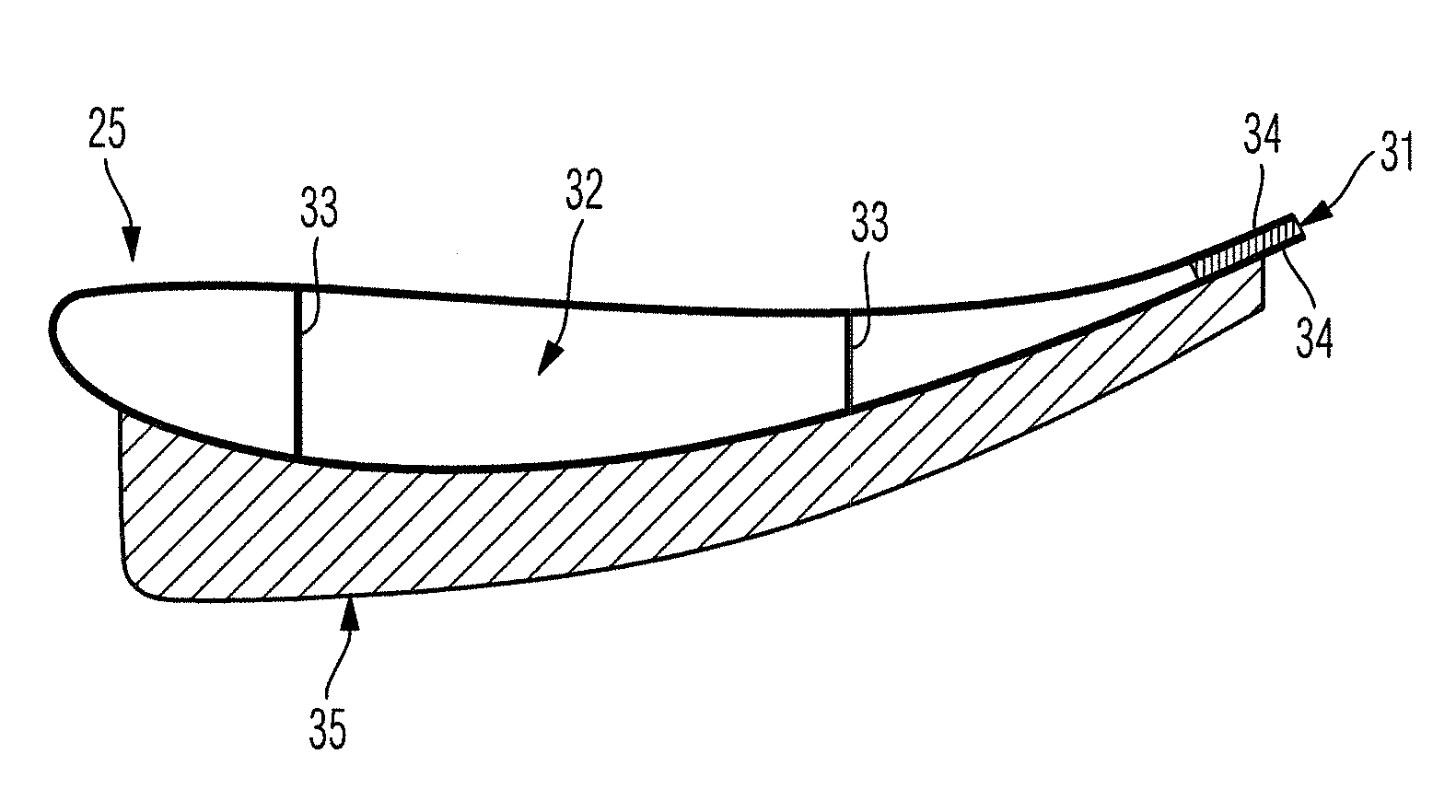

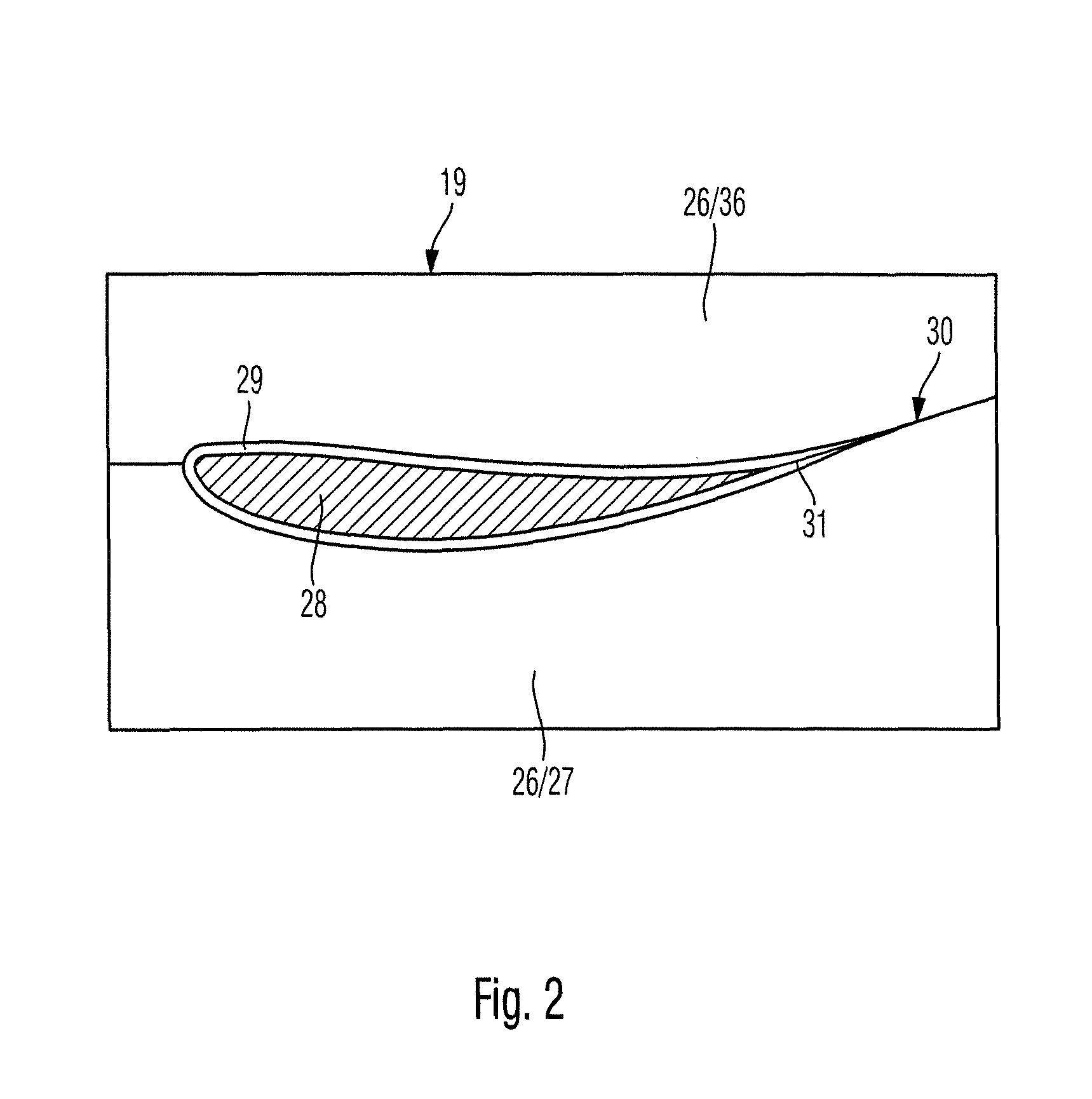

A process for producing hollow fiber-reinforced components includes impregnating fibers with an impregnating material, preorienting the impregnated fibers, passing the pre-oriented fibers through a heated extrusion die to cure the impregnating material and to form a hollow profile and detaching segments from the hollow profile. The process further includes placing a separating film between the impregnated fibers at one position of the hollow profile prior to curing. The separating film prevents the fibers from bonding as the impregnating material is cured. A segment produced in this way is swung open at the position of the separating film. A subassembly is positioned inside the swung-open segment and then adjacent portions of the segment are permanently bonded together.

Owner:DR ING H C F PORSCHE AG

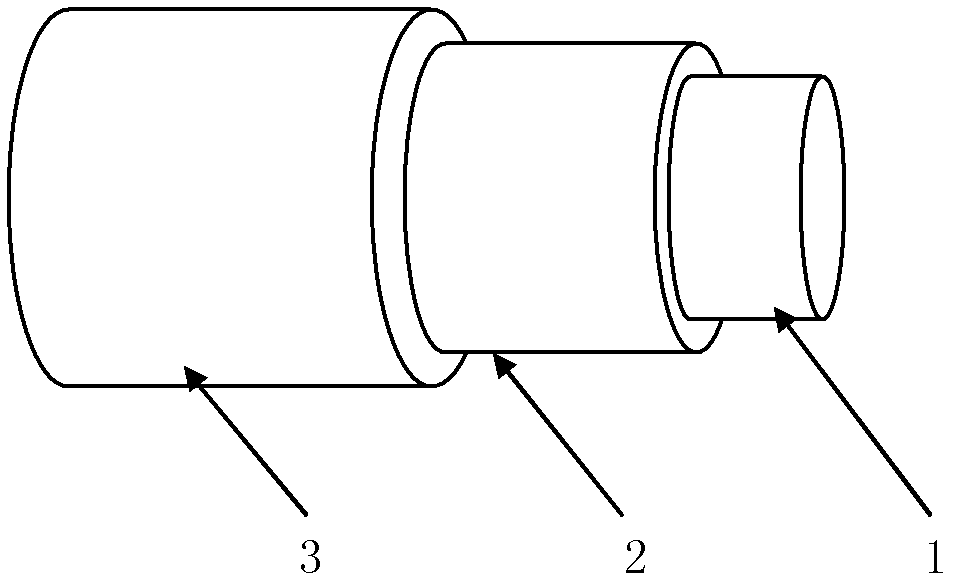

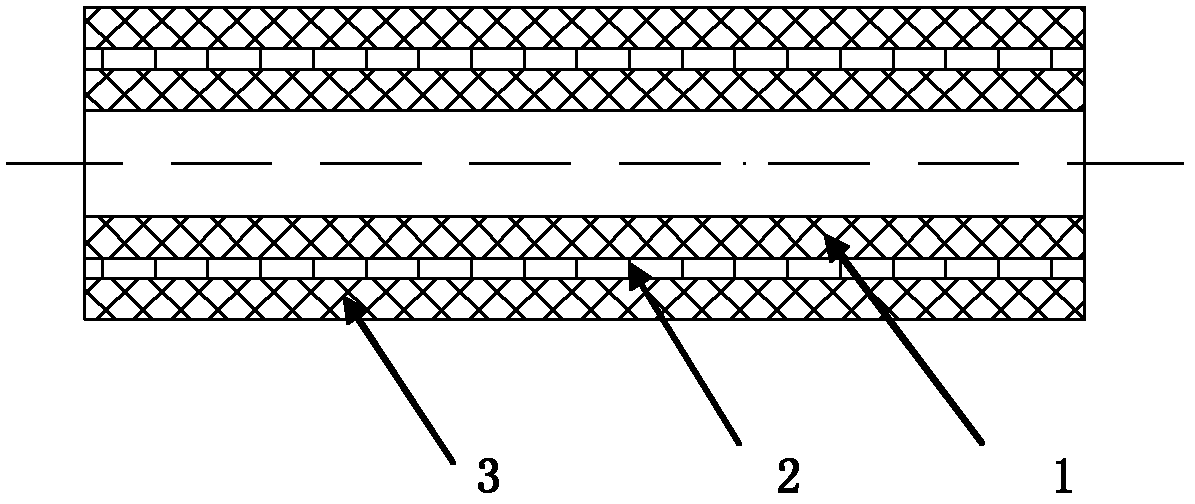

High-property polyurethane nanometer composite flexible pipe and preparation method thereof

InactiveCN106977906AHigh peel strengthHigh compressive strengthLayered productsTubular articlesEpoxyCarbon fibers

The invention provides a high-property polyurethane nanometer composite flexible pipe and a preparation method thereof. The high-property polyurethane nanometer composite flexible pipe is prepared by the following steps of using a composite fiber strip with diameter of 40 to 60cm as a reinforcing layer, using a thermoplastic polyurethane monomer, a modified silicon and cerium nanometer material, rosin resin and epoxy resin as an inner layer and an outer layer, and performing the primary extrusion and forming. The high-property polyurethane nanometer composite flexible pipe has the advantages that a sandwich structure is formed; the composite fiber strip blank is weaved and modified by a circular weaving machine through using aramid fiber as warp yarns, and using aramid fiber and carbon fiber as weft yarns, the modified silicon and cerium nanometer material is prepared by using gamma-glycidoxy propyl trimethoxy silane to activate the surface of the silicon and cerium nanometer material, the silicon and cerium nanometer material has a three-layer core and shell structure, the inner core is of nanometer silicon dioxide, the middle layer is of nanometer cerium dioxide, and the outermost shell is of nanometer titanium dioxide; the compressive strength is 5.2 to 6.4MPa, the stripping strength is 130 to 155N / 25mm, and the change rate of stripping strength is 2% to 5%; the compressive strength is high, the anti-aging property is excellent, the stripping strength is high, and the like; the processing technology is simple and convenient; the composite flexible pipe is mainly used for the transportation of marine petroleum, natural gas and industrial water and the supply of ocean oil.

Owner:SOUTHEAST UNIV

Environment-friendly antibacterial plastic floor and manufacturing process thereof

The invention discloses an environment-friendly antibacterial plastic floor and a manufacturing process thereof. The environment-friendly antibacterial plastic floor is prepared from, by weight, 80-90 parts of waste plastic, 60-80 parts of activated Calcium carbonate, 4-7 parts of chlorinated polyethylene, 2-4 parts of wood powder fibers, 8-14 parts of calcium stearate, 6-12 parts of inorganic nanoparticles, 0.7-2.5 parts of basic amino acid, 0.14-0.28 part of inorganic antibacterial active substances, 1.5-4.5 parts of tetrasodium pyrophosphate decahydrate, 0.15-0.3 part of lauryl phosphate and 12-18 parts of a plasticizer DPO. The plastic floor makes full use of solid waste, so that environment protection is realized while plastic floor manufacturing cost is reduced; in addition, a rate of inhibition and killing of Escherichia coli, staphylococcus aureus and the like is up to 99.5% or above, so that evident antibacterial effects are achieved.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

150 DGE C irradiation crosslinking low-smoke halogen-free antiflaming polyolefin sheathing compound for locomotive thin-walled line as well as preparation and application thereof

The invention relates to a 150 DGE C irradiation crosslinking low-smoke halogen-free antiflaming polyolefin sheathing compound for a locomotive thin-walled line. The sheathing compound is prepared from the following raw material components in parts by weight: 60-90 parts of substrate, 10-40 parts of compatilizer, 50-100 parts of halogen-free flame retardant, 5-30 parts of halogen-free antiflamingauxiliary, 2-4 parts of antioxidant, 0.5-2 parts of lubricant, 1-4 parts of crosslinking sensitizing agent and 1-5 parts of powder dispersing agent. The 150 DGE C irradiation crosslinking low-smoke halogen-free antiflaming polyolefin sheathing compound has the advantages that the cost is relatively low, the whole system dose not contain halogen, and the sheathing compound has scraping resistance,oil resistance, low fuming amount in burning and the like and completely meets the requirement of a cable for the 150 DGE C locomotive thin-walled line.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

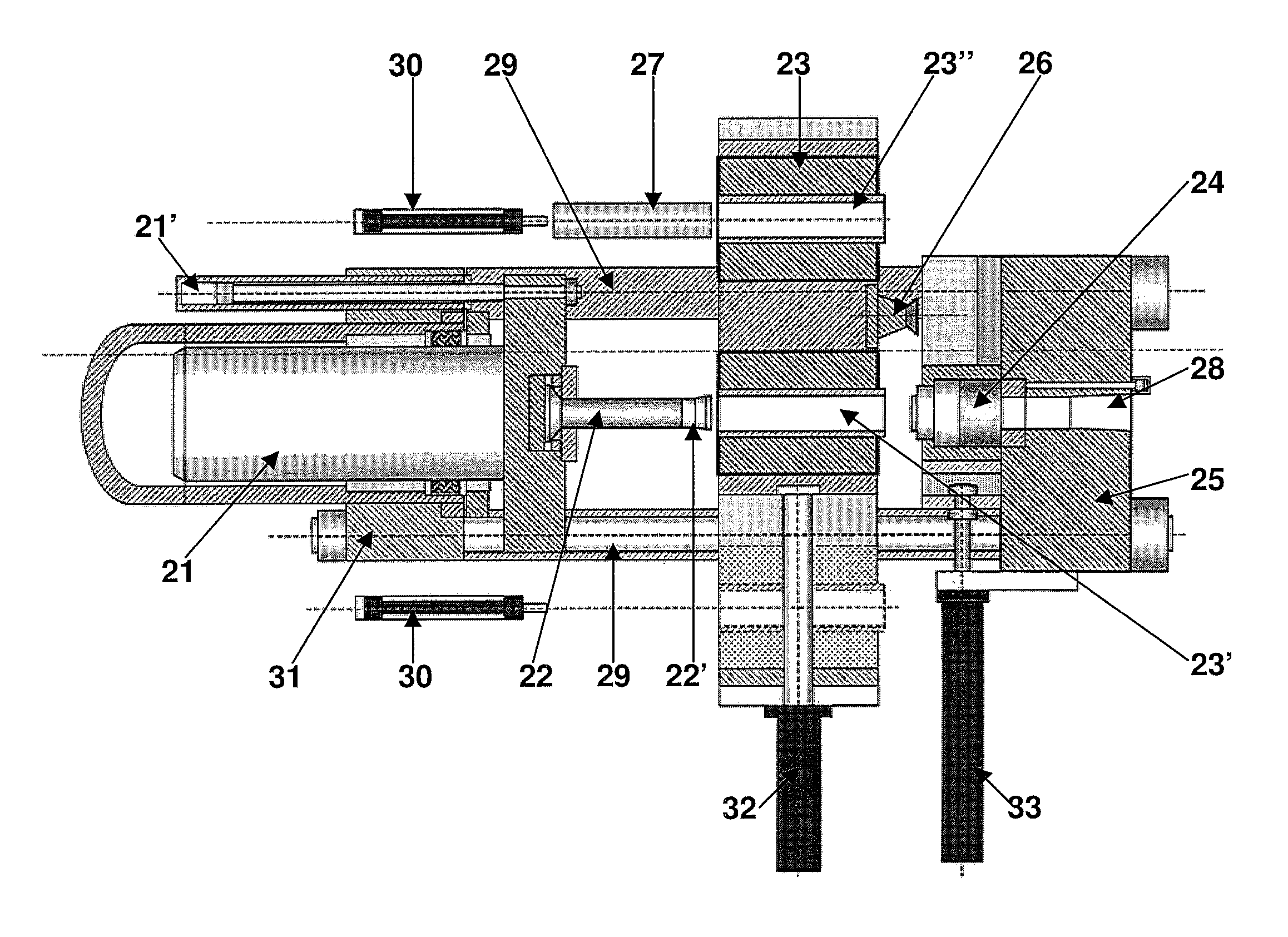

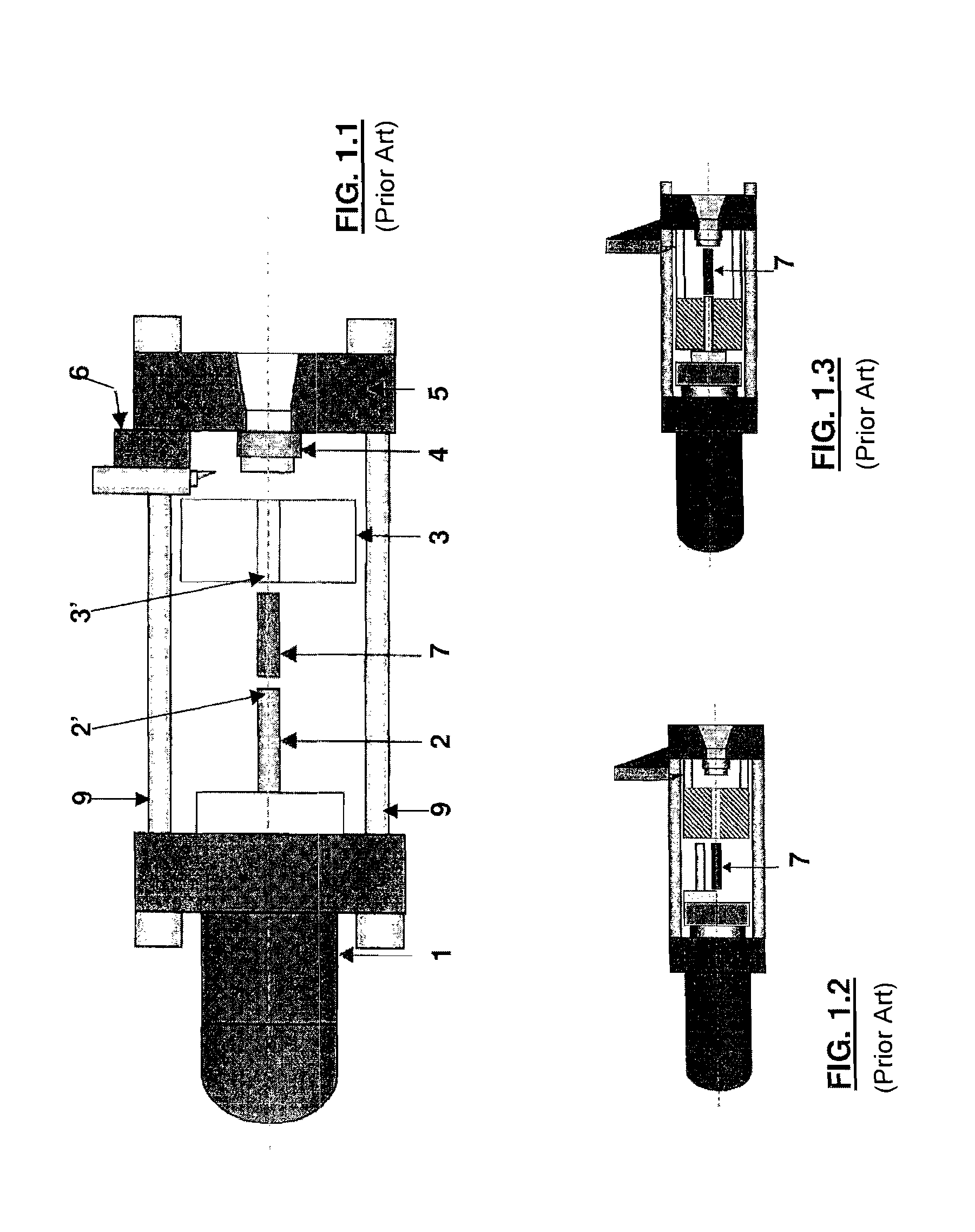

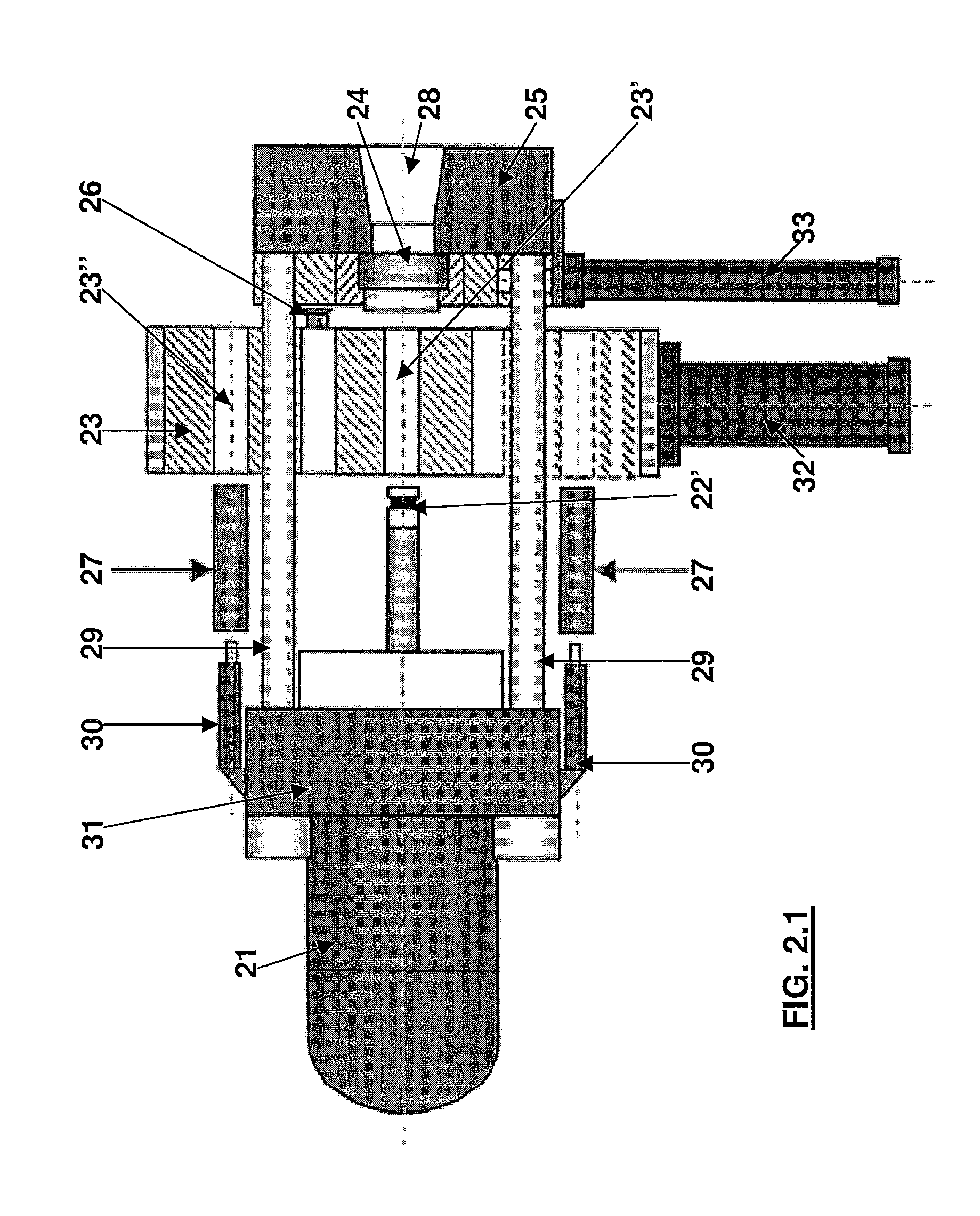

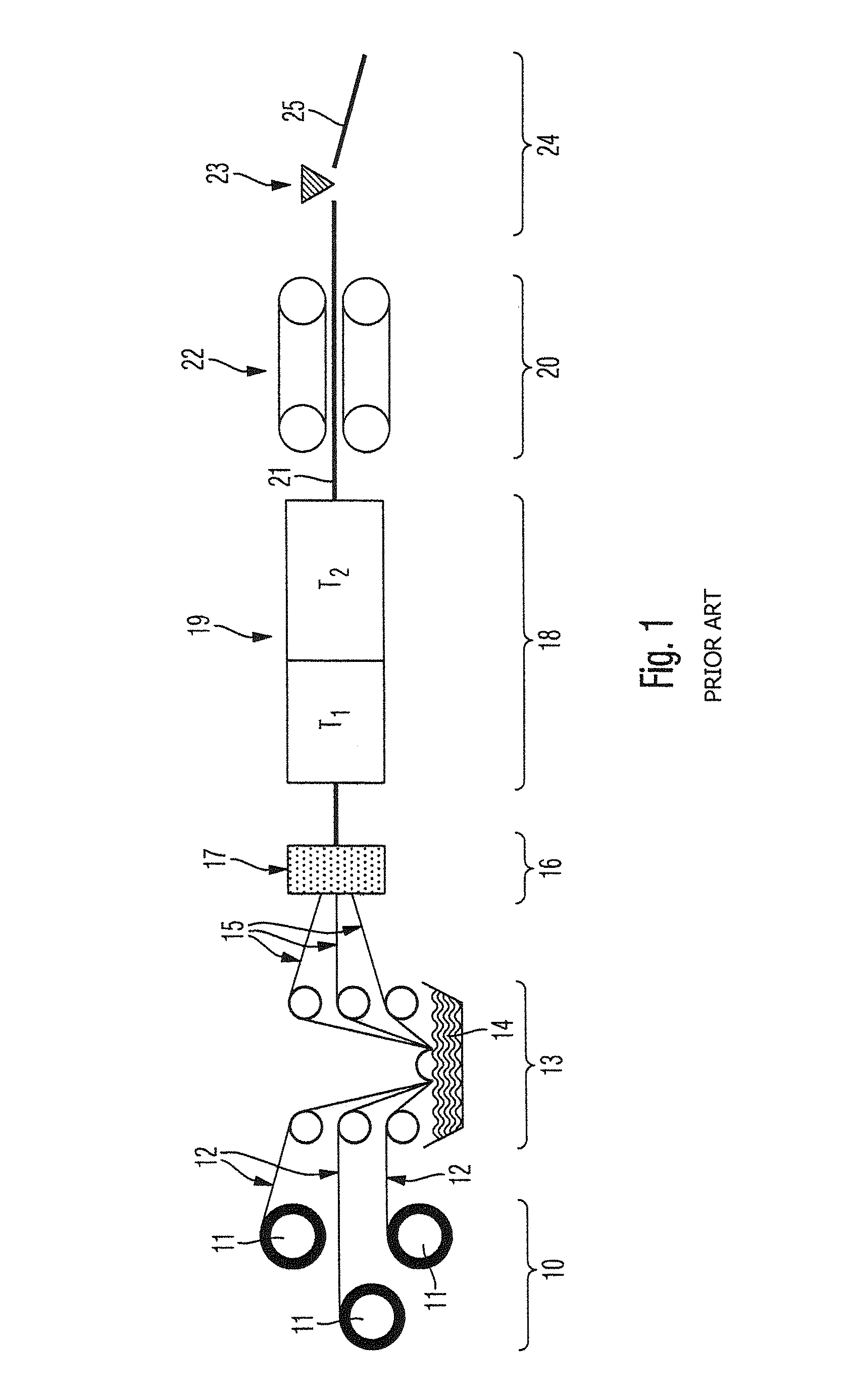

Multifunctional extruding press with multiple equipment and extrusion method thereof

InactiveUS8613212B2Reduce dead timeExtended production timeExtrusion containersPressesComing outEngineering

An extruding press comprising: a die platen element (25) with an extrusion matrix (24) from which an extruded product comes out; a main cylinder (21); longitudinal columns (29) connecting the die platen element (25) to the main cylinder (21); a multiple equipment provided with at least two containers (23′, 23″) for housing the billets, and comprising an external, longitudinally moving, cross element and a transversally moving ram inside said cross element which comprises the containers; means for longitudinally moving the cross element and means for transversally moving the internal ram to make one of the containers (23′, 23″) face the extrusion matrix (24) and make one or more of the other containers be in front of the billet introducing means (30) at the same time as said extrusion of the billet.

Owner:DANIELI & C OFF MEC SPA

150DEG C irradiation crosslinking low-smoke halogen-free flame retardant polyolefin material for locomotive wires and its preparation

ActiveCN102898716BHigh temperature resistanceGood oil resistancePlastic/resin/waxes insulatorsPolyolefinAntioxidant

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

Automobile electric wire with fire-resistant and flame-retardant performance

InactiveCN103497404ASimple extrusion processLow costInsulated cablesInsulatorsAging resistanceEngineering

The invention discloses an automobile electric wire with fire-resistant and flame-retardant performance. The automobile electric wire is characterized by consisting of the following components in parts by weight: 60 to 70 parts of polyethylene rubber, 5 to 10 parts of a peroxide crosslinking agent, 3 to 5 parts of flame-retardant oil, 3 to 8 parts of silicon dioxide, 2 to 5 parts of kaolin, 6 to 8 parts of fossil meal and 5 to 10 parts of an anti-ageing agent. A high-temperature-resistant flame-retardant insulating material provided by the invention can work for a long time at 125 DEG C, even 150 DEG C, has high ageing resistance, can resist the low temperature of -40 DEG C, and has excellent wear resistance, flame resistance, oil resistance and mildew resistance. A product can meet the T3 and T4 standard requirements in DINISO6722 after being manufactured into an automobile wire, thereby being a novel automobile wire material. In addition, the electric wire disclosed by the invention is simple in extrusion process and low in cost.

Owner:QINGDAO SANLI XINYUAN ELECTRICAL APPLIANCES

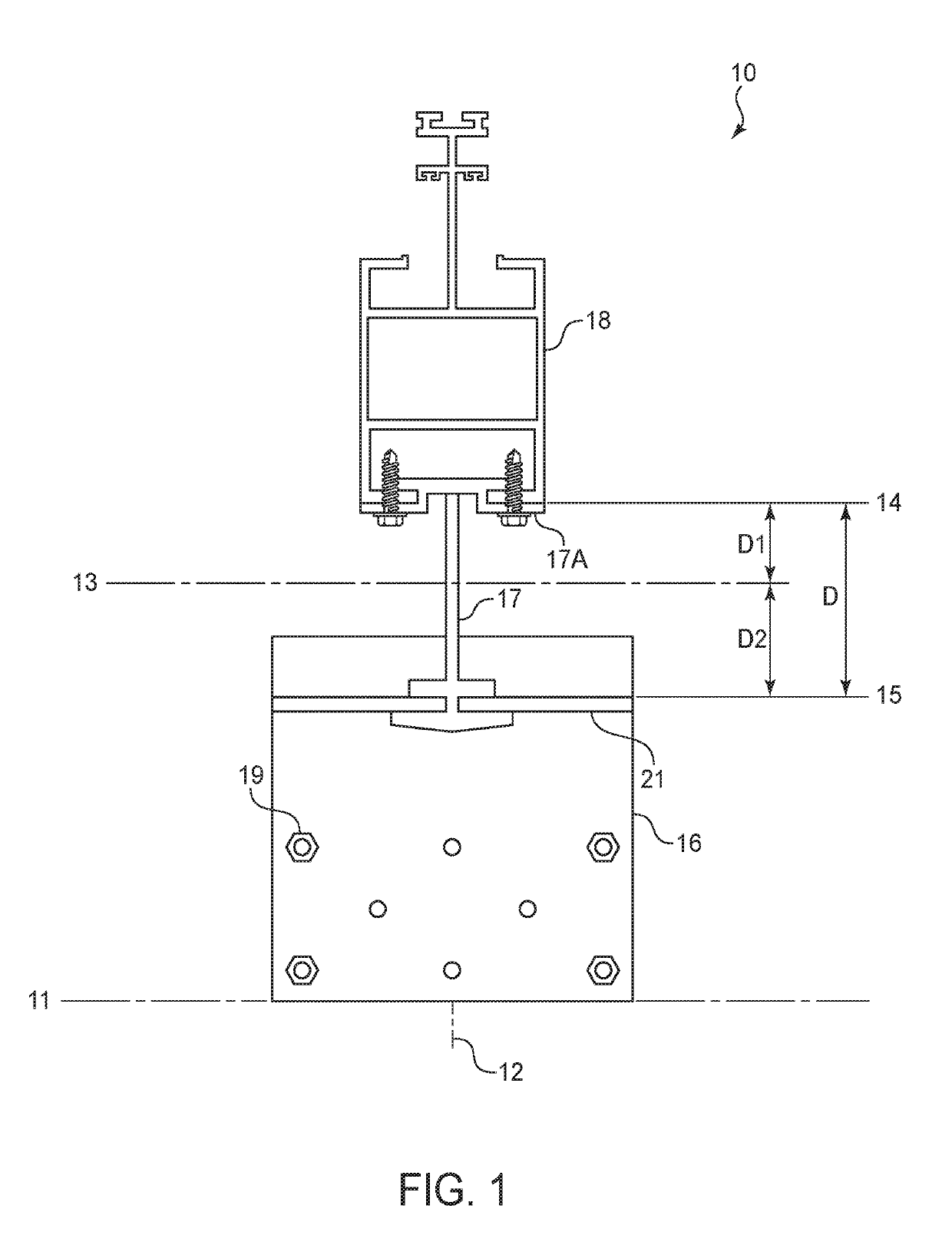

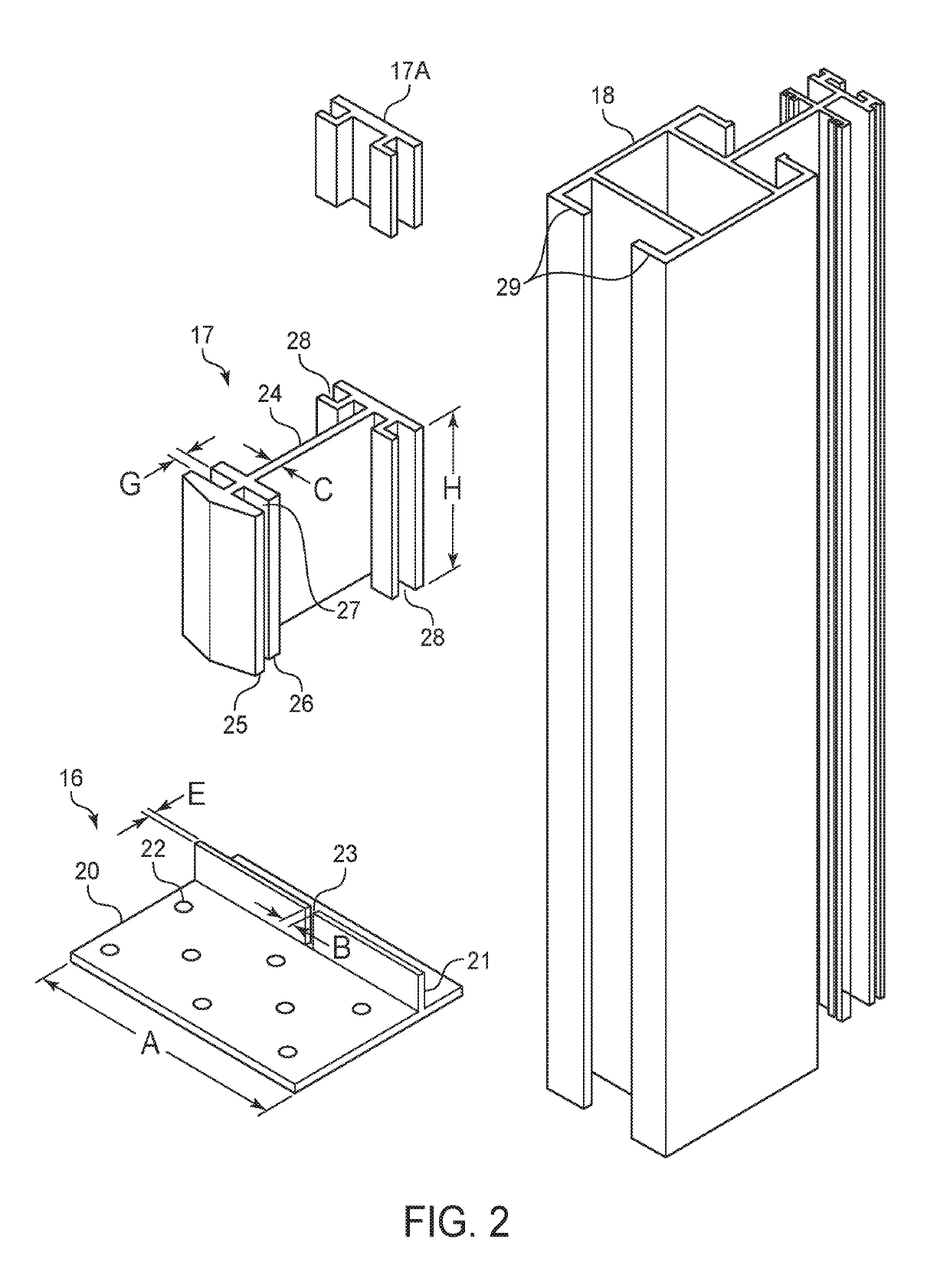

Advanced curtain wall mullion anchoring system

A curtain wall mullion anchoring system that does not require adjustability among the anchoring system components and the mullion to account for construction tolerance. The anchoring device can be accurately installed on a cured concrete floor slab at the proper in-and-out and left-and-right positions. A mullion connector is engaged with the anchoring device and the mullion to transfer reaction forces on the mullion to the building structure via the anchoring device. The mullion connector is slidably engaged with the mullion such that the mullion connector can slide along the length of the mullion and will be placed at the proper up-and-down position by simply sliding the mullion connector down the mullion to the anchoring device on the concrete floor slab.

Owner:TING RAYMOND M L

Electric wire capable of resisting high temperature of 1000 DEG C and preparation method thereof

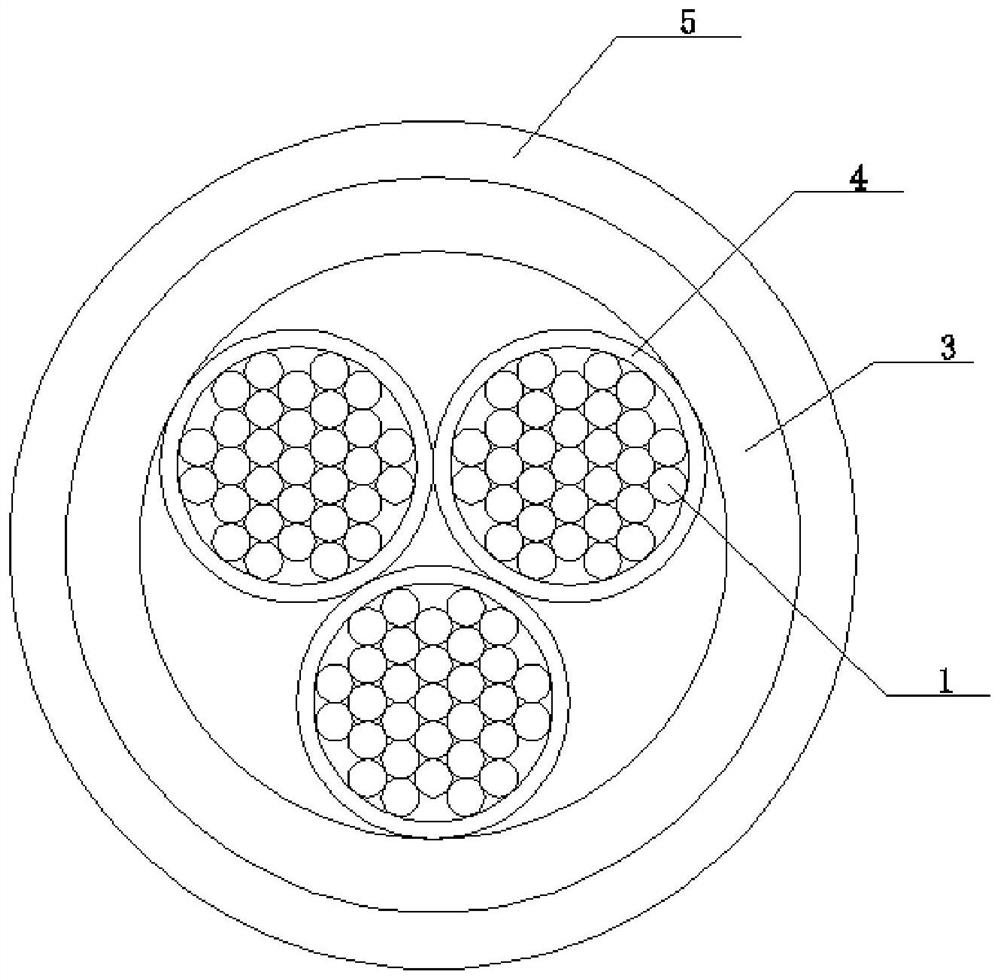

ActiveCN111755163AAnti aging catalysisGuaranteed service lifeRubber insulatorsClimate change adaptationElectrical conductorInsulation layer

The invention discloses an electric wire capable of resisting high temperature of 1000 DEG C, which comprises multiple sets of conductors, and further comprises a belting layer and a braided shieldinglayer, wherein the conductors are coated with insulating layers to form insulating wire cores, the three insulating wire cores are combined and are coated with the braided shielding layer, the braided shielding layer is sequentially coated with an elastic heat insulation layer and a loose tube from inside to outside to form main wire cores, a reinforcing core is arranged among the plurality of main wire cores, the plurality of main wire cores are all arranged in a belting layer, the belting layer is sequentially coated with a braided heat-resistant layer, an inner sheath, a braided armor layer and an outer sheath from inside to outside, and the belting layer is filled with heat insulation flame-retardant particles. The conductor is externally provided with a ceramic silicone rubber insulating layer, so that the fireproof performance of the conductor insulating layer can be effectively improved; compared with a transmission oxidized mineral insulating layer, the fireproof performance,the flame-retardant performance, the low-smoke performance, the non-toxic performance and other characteristics are excellent; and the belting tape layer is filled with the heat-insulation flame-retardant particles, the good heat-insulation flame-retardant effect can be achieved, and meanwhile, the structural stability and the weighing performance of the cable can be effectively improved.

Owner:TIANCHANG HUILING ELECTRIC APPLIANCE METER FACTORY

High-temperature-resistant silane-crosslinked flame-retardation insulating material for automobile wires and preparation method thereof

ActiveCN103059374BImprove aging resistanceImprove wear resistanceInsulated cablesCable/conductor manufactureLow-density polyethyleneElastomer

The invention relates to a high-temperature-resistant silane-crosslinked flame-retardation insulating material for automobile wires. The material comprises basic master batches, functional master batches and catalysis master batches with a weight ratio of 100 : 25-40 : 5-10, wherein the basic master batches comprise high-density polyethylene resin, polyester elastomer, hydrogenated nitrile rubber, maleic anhydride monomer, a silane cross-linking agent, a peroxide initiator, an anti-oxidant and a lubricant; the functional master batches comprise the high-density polyethylene resin, the polyester elastomer, a fire retardant, a wear-resistant agent, a lubricant and a bacteria-resistant agent; and the catalysis master batches comprise the high-density polyethylene resin, low-density polyethylene resin, a crosslinking catalyst and the anti-oxidant. The high-temperature-resistant silane-crosslinked flame-retardation insulating material meets requirements of T3 and T4 standards of DINISO6722 T1 to T4, can be used as novel materials for the automobile wires, and is free of irradiation and low in technology cost.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

Ceramic silica gel cable

InactiveCN108831597AImprove practicalityReduce manufacturing costClimate change adaptationInsulated cablesCombustionInsulation layer

The invention discloses a ceramic silica gel cable. The ceramic silica gel cable comprises a conductor; the conductor is sleeved with a shielding layer; the shielding layer is sleeved with a mica rewinding layer; the mica rewinding layer is sleeved with a core ceramic silica gel insulation layer; a ceramic silica gel protection sleeve is arranged outside the core ceramic silica gel insulation layer; and a filling layer is arranged between the core ceramic silica gel insulation layer and the ceramic silica gel protection sleeve. The core ceramic silica gel insulation layer in the scheme is theceramic silica gel insulation layer, the ceramic silica gel processing process is simple and has a higher production efficiency compared with the current fire resistant wire and cable production process, the production energy consumption can be reduced, the cost is saved, the practicability of the cable is improved, the ceramic silica gel has excellent fireproof, flame retardant, low-smoke, non-toxic and other characteristics, the extrusion molding process is simple, the residue after combustion is a hard ceramic shell, better fireproof effects can be achieved, arranged hollow hoses can reducethe weight of the cable, the cable can be used better, and the practicability of the cable is improved.

Owner:沪如科技南京有限公司

Process for producing components

A process for producing hollow fiber-reinforced components includes impregnating fibers with an impregnating material, preorienting the impregnated fibers, passing the pre-oriented fibers through a heated extrusion die to cure the impregnating material and to form a hollow profile and detaching segments from the hollow profile. The process further includes placing a separating film between the impregnated fibers at one position of the hollow profile prior to curing. The separating film prevents the fibers from bonding as the impregnating material is cured. A segment produced in this way is swung open at the position of the separating film. A subassembly is positioned inside the swung-open segment and then adjacent portions of the segment are permanently bonded together.

Owner:DR ING H C F PORSCHE AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com