150 DGE C irradiation crosslinking low-smoke halogen-free antiflaming polyolefin sheathing compound for locomotive thin-walled line as well as preparation and application thereof

A technology of polyolefin sheathing and irradiation, which is applied in the direction of conductors, electrical components, circuits, etc., and can solve the problems of no industrialization, difficult control of extrusion process, and inability to extrude with ordinary extrusion equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

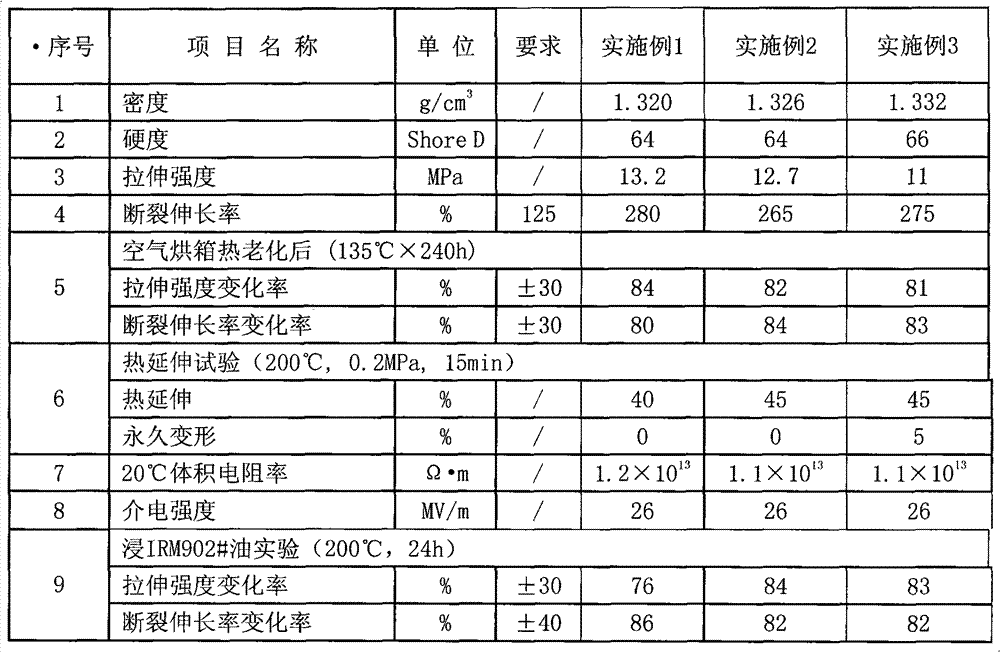

Examples

Embodiment 1

[0034] The raw material components are as follows:

[0035] Ingredient parts by mass

[0036] HDPE density is 0.954 80 parts

[0037] POE5062 graft melt index 0.620 parts

[0038] Methyl silicone rubber compound 10 parts

[0039] Magnesium hydroxide 80 parts

[0040] Antimony trioxide 10 parts

[0041] Antioxidant 1010 4 parts

[0042] 1 part magnesium stearate

[0043] Polyethylene wax 0.2 parts

[0044] Triallyl isocyanurate 3 parts

[0045] A17 23 copies

[0046] Preparation method: The above raw material components are mixed by a plastic high mixer, plasticized and granulated by a twin-screw extrusion granulator and dried to obtain the product.

Embodiment 2

[0048] The raw material components are as follows:

[0049] Ingredient parts by mass

[0050] HDPE density is 0.958 85 parts

[0051] POE5062 graft melt index 0.6 15 parts

[0052] Methyl silicone rubber compound 8 parts

[0053] Magnesium hydroxide 85 parts

[0054] Antimony trioxide 10 parts

[0055] Antioxidant 1010 4 parts

[0056] 1 part magnesium stearate

[0057] Polyethylene wax 0.2 parts

[0058] Triallyl isocyanurate 3 parts

[0059] A172 3 copies

[0060] The preparation method is the same as in Example 1.

Embodiment 3

[0062] The raw material components are as follows:

[0063] Ingredient parts by mass

[0064] HDPE density is 0.958 90 parts

[0065]POE5061 graft melt index 0.6 10 parts

[0066] Methyl silicone rubber compound 10 parts

[0067] Magnesium hydroxide 90 parts

[0068] Antimony trioxide 10 parts

[0069] Antioxidant 1010 4 parts

[0070] 1 part magnesium stearate

[0071] Polyethylene wax 0.2 parts

[0072] Triallyl isocyanurate 3 parts

[0073] A172 3 copies

[0074] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com