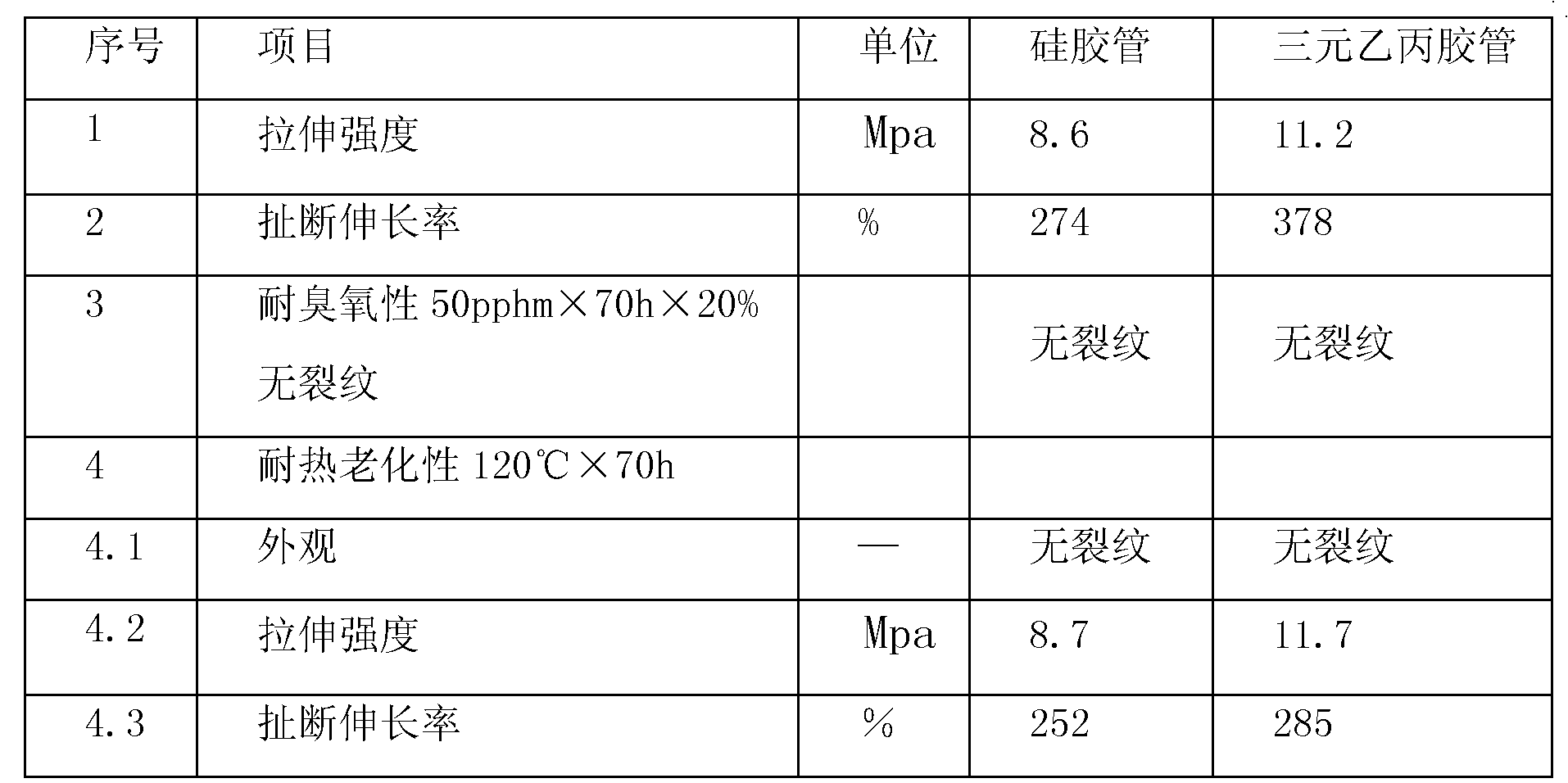

Ethylene propylene diene rubber composition for air outlet pipe of intercooler and preparation method thereof

A technology of EPDM rubber and composition, applied in the direction of hoses, pipes, mechanical equipment, etc., can solve the problems of rising automobile manufacturing costs and excess performance, and achieve suitable performance, low price, and good heat aging resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

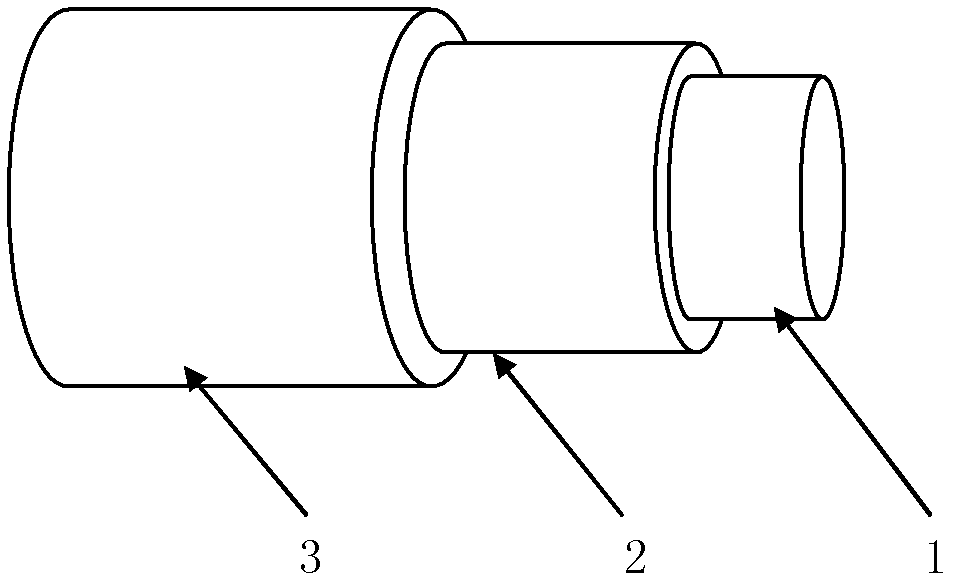

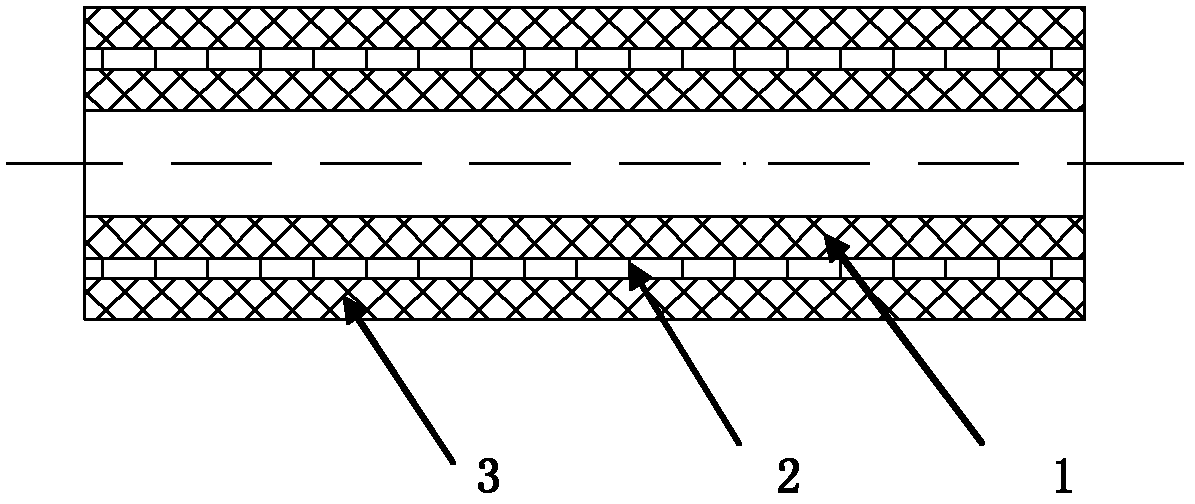

[0028] To produce an intercooler outlet hose with a size of 41±0.5mm×51±0.5mm×630±3mm, the steps are as follows:

[0029] 1. Tube embryo manufacturing process

[0030] A pin-barrel cold-feed extruder with an aspect ratio of 11 was selected.

[0031] Extrusion inner rubber: head temperature: 60°C, extrusion section temperature: 50°C, plasticizing section temperature: 50°C, feeding section temperature: 50°C.

[0032] The reinforcement layer is made of aramid thread and has a knitted structure.

[0033] Extrusion cover: head temperature: 60°C, extrusion section temperature: 50°C, plasticizing section temperature: 50°C, feeding section temperature: 50°C. And choose a 41mm needle and a 48mm mouth shape to ensure the size of the hose.

[0034] 2. Cooling

[0035] After the rubber is extruded from the machine head, the temperature is high, and it is cooled. The temperature of the circulating water is controlled at 15±5°C, cooled and shaped, the cutting length is 230mm, and...

Embodiment 2

[0045] To produce an intercooler outlet hose with a size of 50±0.5mm×60±0.5mm×520±3mm, the steps are as follows:

[0046] 1. Tube embryo manufacturing process

[0047] A pin-barrel cold-feed extruder with a length-to-diameter ratio of 12 was selected.

[0048] Extrusion inner rubber: head temperature: 80°C, extrusion section temperature: 70°C, plasticizing section temperature: 70°C, feeding section temperature: 60°C.

[0049] The reinforcement layer is made of aramid thread and has a knitted structure.

[0050] Extrusion cover: head temperature: 80°C, extrusion section temperature: 70°C, plasticizing section temperature: 70°C, feeding section temperature: 60°C. And choose a 51mm needle and a 57mm mouth shape to ensure the size of the hose.

[0051] 2. Cooling

[0052] After the rubber is extruded from the machine head, the temperature is high, and it is cooled. The temperature of the circulating water is controlled at 15±5°C, cooled and shaped, the cutting length is...

Embodiment 3

0

[0064] To produce an intercooler outlet hose with a size of 48±0.5mm×57±0.5mm×745±3mm, the steps are as follows:

[0065] 1. Tube embryo manufacturing process

[0066] A pin-barrel cold-feed extruder with an aspect ratio of 15 was selected.

[0067] Extrusion inner rubber: head temperature: 70°C, extrusion section temperature: 60°C, plasticizing section temperature: 60°C, feeding section temperature: 55°C.

[0068] The reinforcement layer is made of aramid thread and has a knitted structure.

[0069]Extrusion cover: head temperature: 70°C, extrusion section temperature: 60°C, plasticizing section temperature: 60°C, feeding section temperature: 55°C. And choose a 49mm needle and a 55mm mouth shape to ensure the size of the hose.

[0070] 2. Cooling

[0071] After the rubber is extruded from the machine head, the temperature is high, and it is cooled. The temperature of the circulating water is controlled at 15±5°C, cooled and shaped, the cutting length is 745...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com