Extrusion-grade fluororubber premix with low fuel oil permeability and preparation method thereof

A technology for fuel permeability and fluororubber raw rubber, applied in the field of fluororubber materials, can solve the problems of poor smoothness and flatness of the inner and outer walls of the hose, poor extrusion flow performance, poor composite bonding performance, etc., to meet environmental emissions. Standard, the effect of reducing extrusion expansion ratio, improving extrusion processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1.1 Preparation of fluororubber premix:

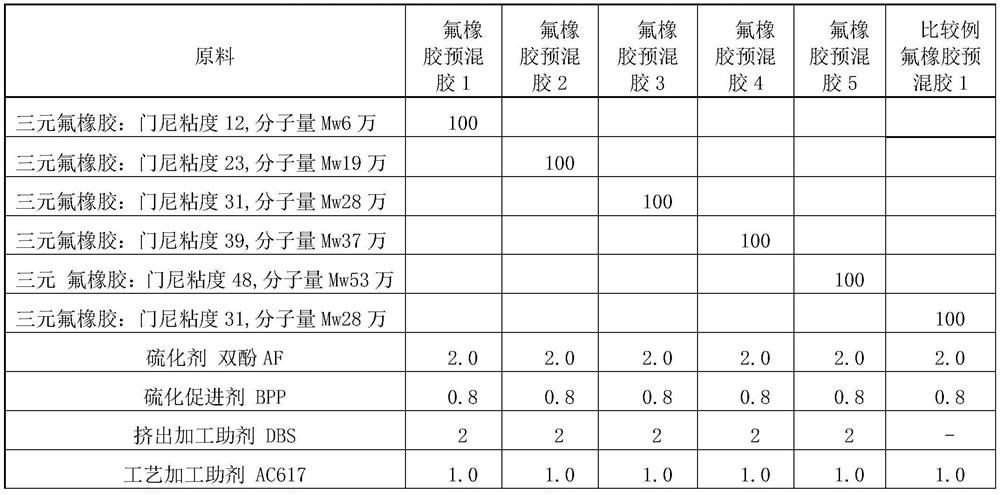

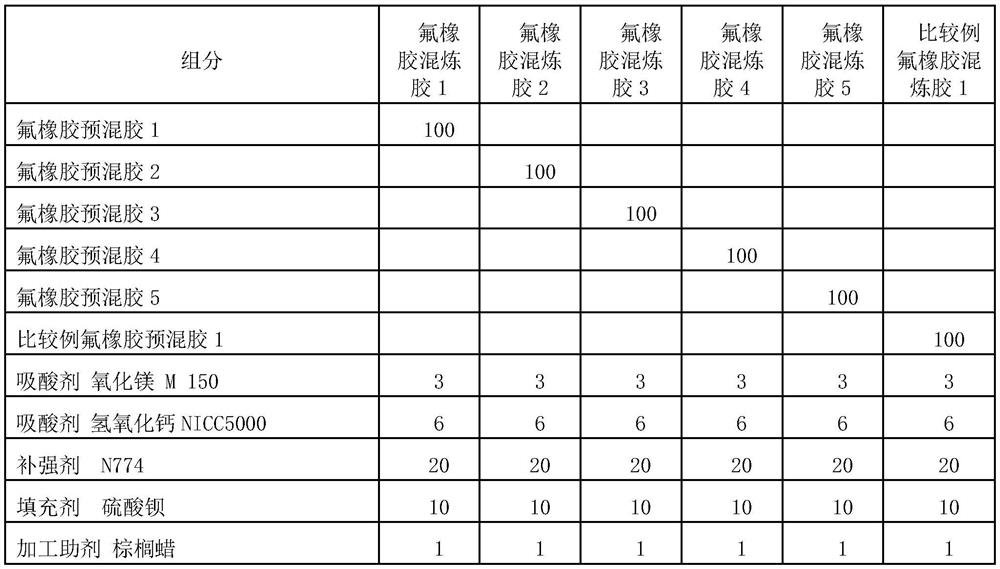

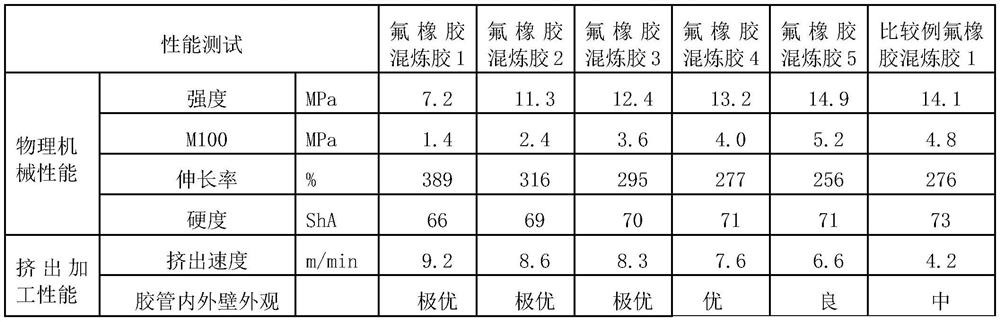

[0042] The fluorine content is 69%, the molecular weight distribution is wide, Mw / Mn≧5, the molecular weight Mw is 60,000, 190,000, 280,000, 370,000, and 530,000, respectively, and the corresponding Mooney viscosity ML121°C (1+10) is 12, 23, 31, 39, 48, each 30kg of ternary fluororubber raw rubber of five different Mooney viscosities; according to the formula table of fluororubber premixed rubber in the following table 1 (each raw material is calculated by weight) and ready for use . Prepare fluororubber premixed rubber 1, fluororubber premixed rubber 2, fluororubber premixed rubber 3, fluororubber premixed rubber 4, and fluororubber premixed rubber 5 according to the following preparation methods:

[0043] Table 1 Fluorine rubber premix formula table (embodiment 1 and comparative example 1)

[0044]

[0045] Preparation:

[0046]A1. According to the ratio, put 30kg of corresponding raw rubber into a 20L internal mixer for...

Embodiment 2

[0066] 2.1 Preparation of fluororubber premix:

[0067] Take 90 kg of ternary fluororubber raw rubber with a fluorine content of 69%, a wide molecular weight distribution, a molecular weight Mw of 260,000, and a Mooney viscosity of ML121°C (1+10) of 28, and use the fluororubber premixed rubber in Table 4 below The fluororubber premixed rubber 6-9 in the formula table (each raw material is calculated by weight) is ready for use; the fluorine content is 69%, the bimodal distribution, the molecular weight Mw is 330,000, and the Mooney viscosity ML is 121°C (1+10) 30 ternary fluororubber raw rubber 60kg, prepared by fluororubber premixed rubber 10-11 in the fluororubber premixed rubber formula table (each raw material is by weight) in the following table 4, ready for use, according to the following Preparation method Prepare fluororubber premix 6, fluororubber premix 7, fluororubber premix 8, fluororubber premix 9, fluororubber premix 10, fluororubber premix 11 in sequence:

[00...

Embodiment 3

[0091] 3.1 Preparation of fluororubber premix:

[0092] Take 180kg of ternary fluororubber raw rubber with a fluorine content of 69%, a molecular weight bimodal distribution, a molecular weight Mw of 330,000, and a Mooney viscosity of ML121°C (1+10) respectively being 30, and premix the fluororubber according to the following table 7. The fluororubber premixed rubber 12-17 in the rubber formula table (each raw material is calculated by weight) is ready for use. Prepare fluororubber premixed rubber 12, fluororubber premixed rubber 13, fluororubber premixed rubber 14, fluororubber premixed rubber 15, fluororubber premixed rubber 16, fluororubber premixed rubber 17 according to the following preparation method:

[0093] Table 7 Fluorine rubber premix formula table (embodiment 3 and comparative example 3)

[0094]

[0095] Preparation:

[0096] A1. According to the ratio, put 30kg of corresponding raw rubber into a 20L internal mixer for 4 minutes of masticating, and the mast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com