Ultraviolet light crosslinking low-smoke zero-halogen flame-retardant cable material and preparation method thereof

A flame retardant cable material and ultraviolet light technology, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of harsh protection conditions, high product rejection rate, complex process flow, etc., and achieve comprehensive mechanical properties. Cost-effective, simple extrusion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0093] The present invention also provides a preparation method of a cable product, the method comprising:

[0094] (1) Preparation of UV cross-linked halogen-free flame retardant cable material: including polyolefin, compatibilizer, inorganic flame retardant, organic phosphorus nitrogen flame retardant, flame retardant synergist, photoinitiator, auxiliary crosslinking agent Agents, surface modifiers, antioxidants and lubricants are mixed, and then extruded and granulated;

[0095](2) coating: the ultraviolet light cross-linked halogen-free flame retardant cable material prepared in step (1) is melted and extruded on the cable conductive wire core, so that the cable conductive wire core is coated with the flame-retardant fuel to form an insulating layer or jacket layer; and

[0096] (3) Ultraviolet light irradiation: ultraviolet light irradiation is performed on the conductive wire core of the cable obtained in step (2) and coated with the resistance fuel.

[0097] In a spec...

Embodiment 1

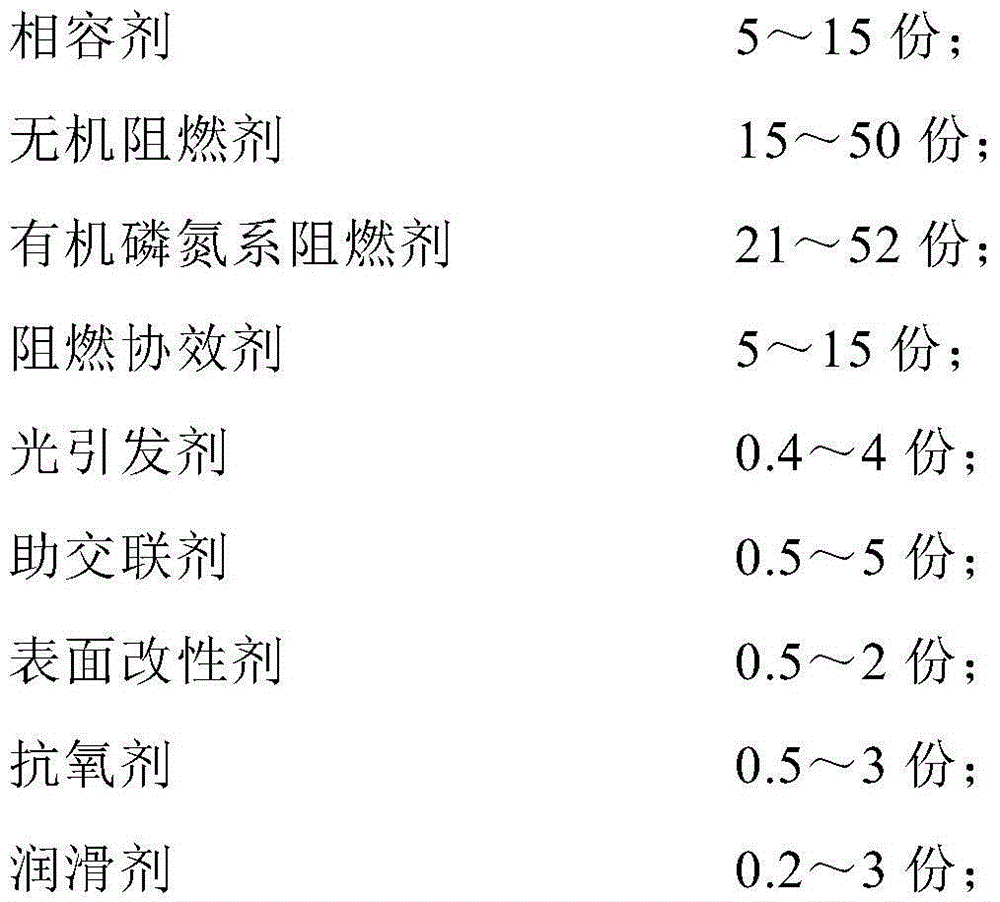

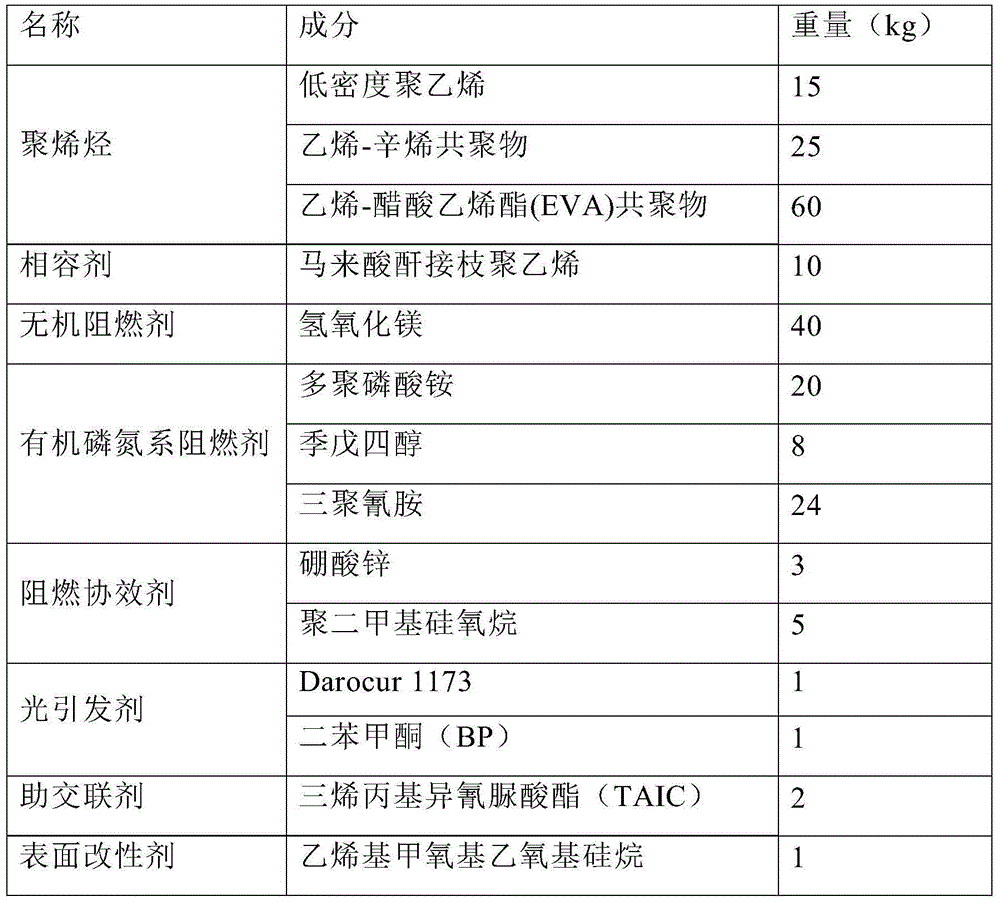

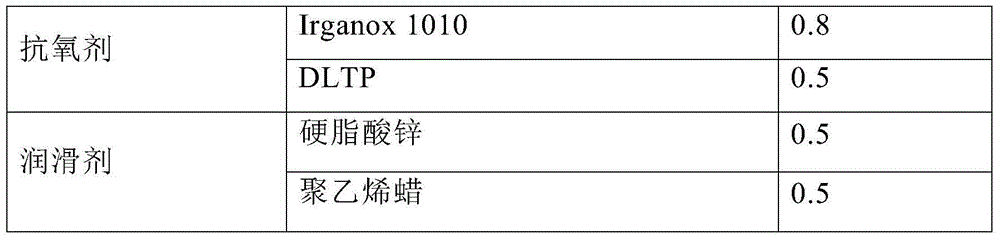

[0112] The name of each component of the formula of Example 1 and the parts by weight of each component are shown in Table 1:

[0113] Table 1

[0114]

[0115]

[0116] Fully mix amine polyphosphate (APP), pentaerythritol (PT) and melamine (M) in a high-speed mixing machine, and then mix with polyolefin, compatibilizer, magnesium hydroxide, flame retardant synergist, The photoinitiator, the auxiliary crosslinking agent, the surface modifier, the antioxidant and the lubricant are extruded and granulated according to the proportions to obtain the ultraviolet light cross-linked low-smoke halogen-free flame retardant cable material. The four temperature sections in the extrusion granulation process are: feeding section 105-115 ℃, conveying section 115-125 ℃, melting section 125-135 ℃, die head 130-140 ℃, screw speed is 50-400rpm.

[0117] Then, the obtained cable material is melted and extruded on the conductive wire core of the cable to coat the fuel-resistant fuel into a...

Embodiment 2

[0120] Each component name of embodiment 2 formula and each component parts by weight are as shown in Table 2:

[0121] Table 2

[0122]

[0123]

[0124] The preparation method of the above-mentioned cable material is the same as that of Example 1.

[0125] A performance test was performed on the product in Example 2, and the performance values are shown in Table 7 of Performance Example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com