Carrier for sheet wafer processing

A flake crystal and carrier technology, used in manufacturing tools, metal processing equipment, stone processing equipment, etc., can solve problems such as increased processing costs, fragmentation of functional wafers, unfavorable production and operation, and improved processing accuracy and efficiency. The effect of improving and avoiding additional labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

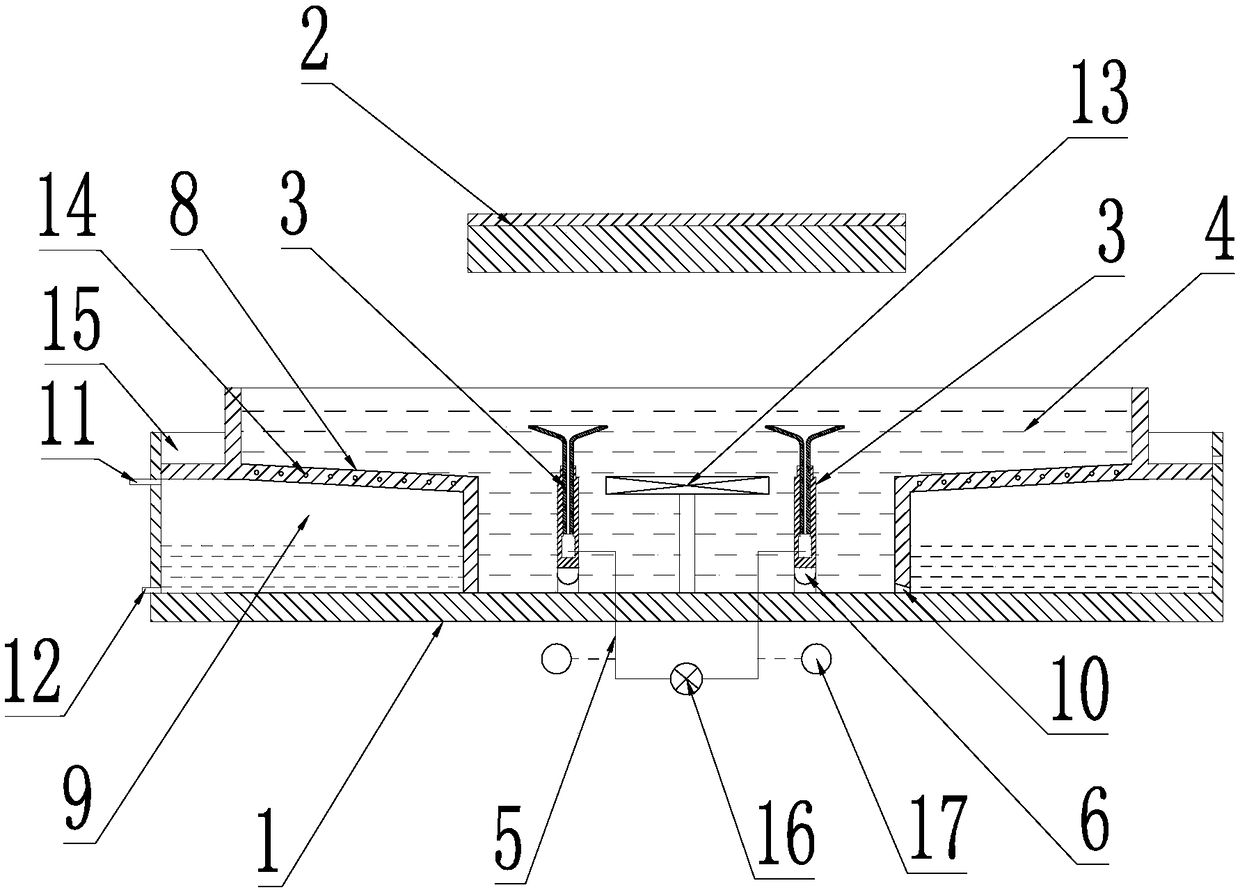

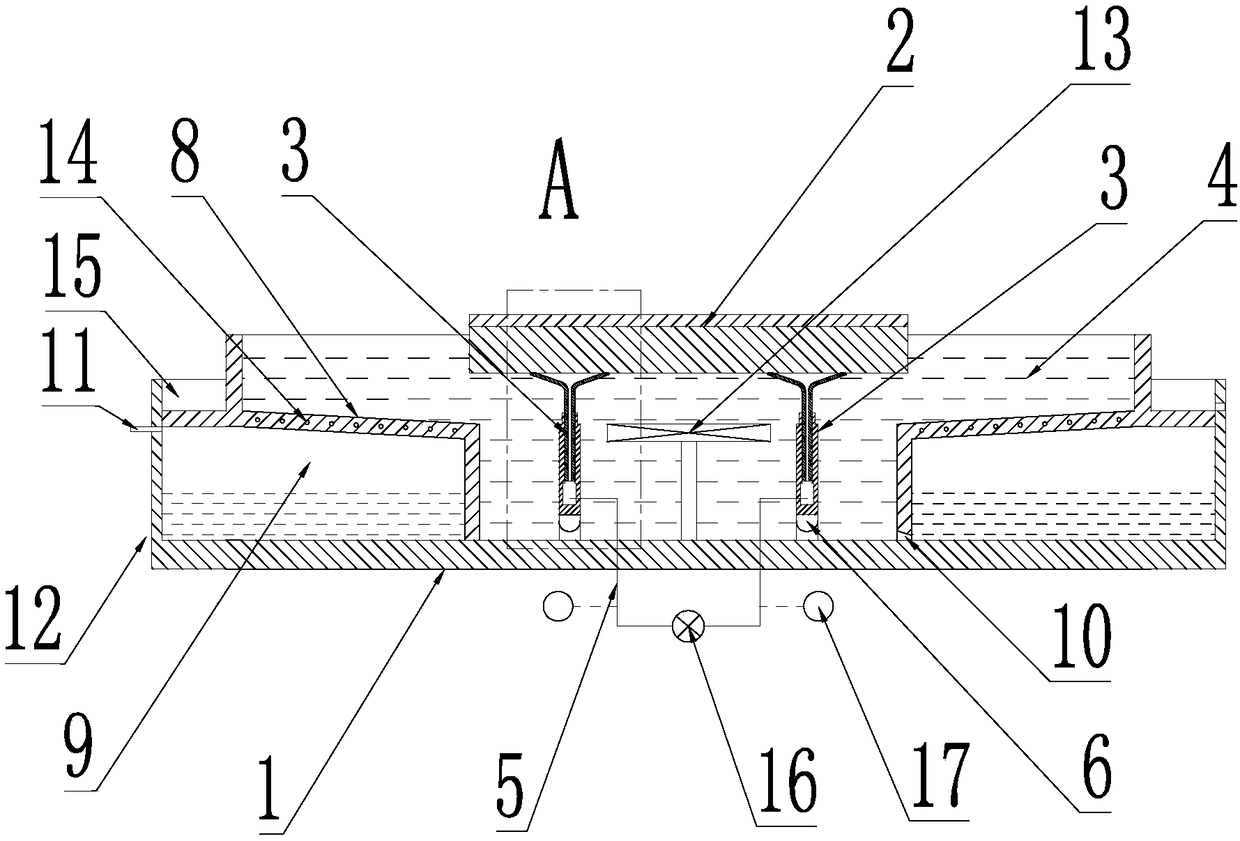

[0026] The invention provides a carrier for sheet wafer processing, which includes such as figure 1 The housing 1 shown with the opening direction upwards is provided with an adjustment mechanism 3 for adjusting the horizontal inclination of the product 2 inside the housing 1, and the magneto-rheological fluid 4 is poured into the housing 1, so that the adjustment mechanism 3 Immersed in the magnetorheological fluid 4, when the lower part of the product 2 is connected to the adjustment mechanism 3, the adjustment mechanism 3 drives the product 2 to swing to the set position and then rests, and the part to be processed of the product 2 is located in the magnetic flow Above the liquid level of the variable fluid 4 , the housing 1 is provided with a magnetic field generator for driving the magnetorheological fluid 4 in the housing 1 to solidify or return to a fluid state.

[0027] The above-mentioned setting position refers to the position of the product to be processed on the ma...

Embodiment 2

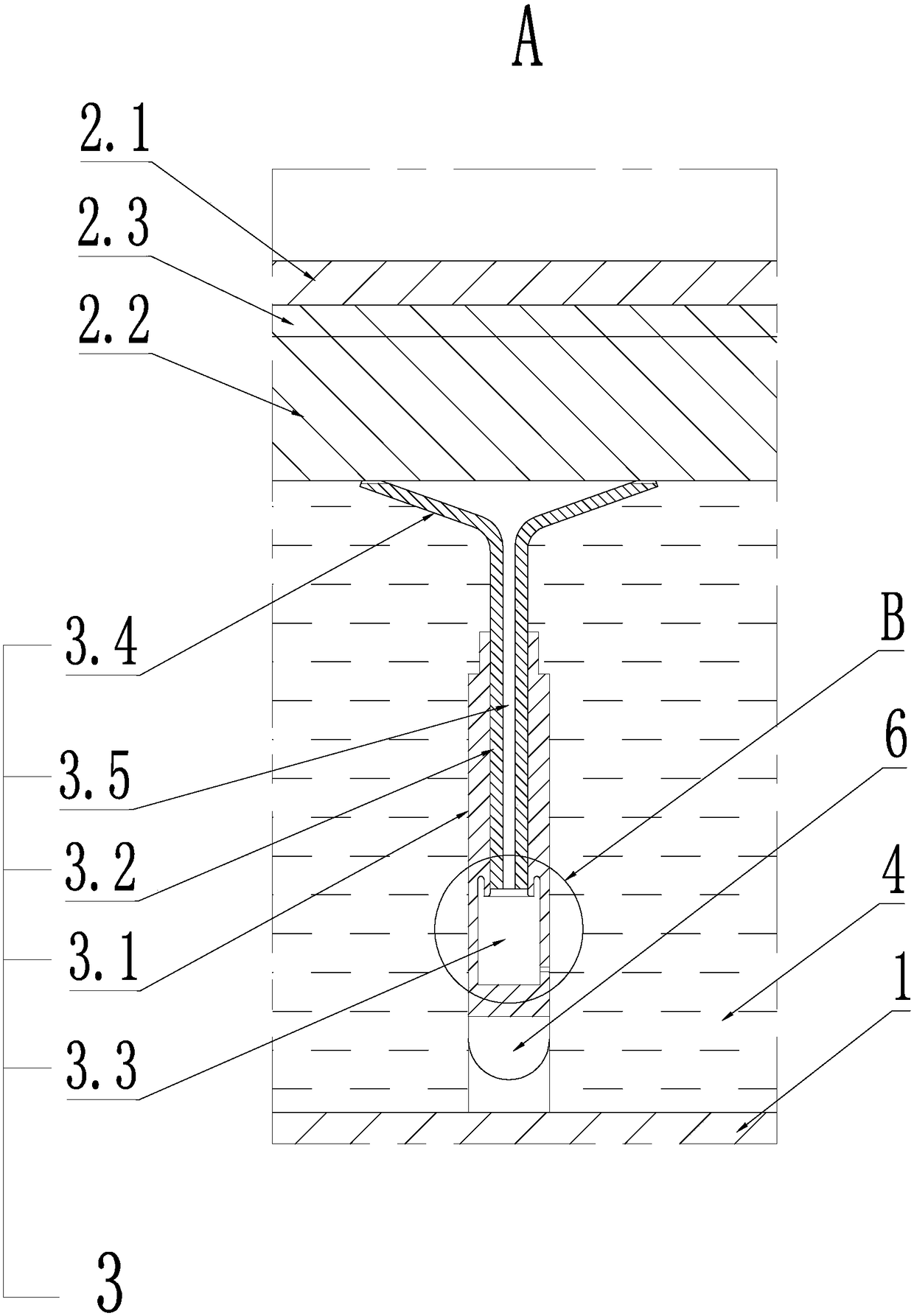

[0031] The general structure is the same as that of Embodiment 1, the difference is that: the adjustment mechanism 3 includes at least three cylinders 3.1, specifically preferably four cylinders 3.1, all cylinders 3.1 are arranged at intervals along the horizontal direction, and each cylinder 3.1 The lower ends are all connected to the housing 1, and a central channel is provided in the cylinder body 3.1, and a piston rod 3.2 is slidably fitted in the central channel, and the lower end surface of the piston rod 3.2 is surrounded by the inner surface of the central channel to form a control chamber 3.3, and the piston rod 3.2 The upper end of the piston rod 3.2 is exposed above the cylinder body 3.1 in the vertical direction, and the end of the piston rod 3.2 exposed above the cylinder body 3.1 is provided with a connecting piece for connecting or disconnecting the product 2.

[0032]The general structure is the same as that of Embodiment 1, the difference is that the adjustment...

Embodiment 3

[0036] The general structure is the same as that of the second embodiment, except that the connecting piece is a suction cup 3.4 with the opening facing upward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com