Circular mold granulator

A ring die granulator and rack technology, applied in the direction of die extrusion granulation, etc., can solve the problems of uneven material entry, low production efficiency, materials concentrated on the top or falling to the bottom, etc., to avoid the lack of close coordination , to ensure the quality of molding, the effect of ensuring the quality of ceramsite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

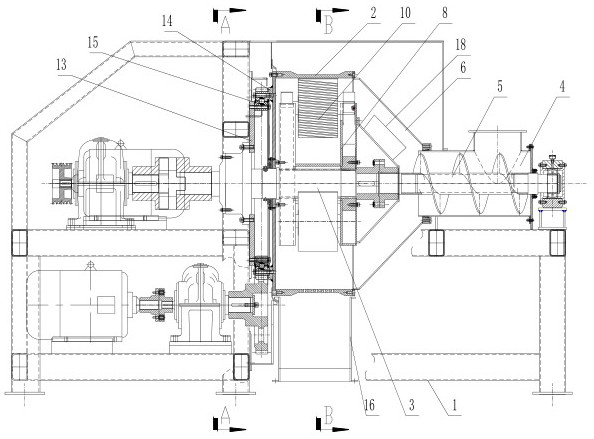

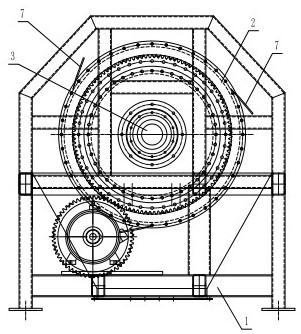

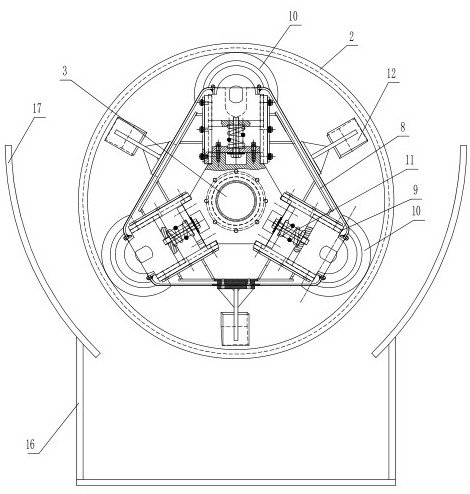

[0024] refer to Figure 1 to Figure 4 As shown, the present invention provides a ring die granulator, for the convenience of description, with figure 1 The left side of the left side is the front side of the machine, which includes a frame 1 and a forming drum 2 connected to the frame 1. The frame 1 is also equipped with a drum power device that drives the forming drum 2 to rotate, and the drum power device is a power machine. Forming drum 2 is densely covered with forming holes through the inside and outside. The frame 1 is connected with the pressure roller main shaft 3 which is powered by the pressure roller driving device and can extend into the forming drum 2. The pressure roller main shaft passes through the forming drum, and the pressure roller drives The device is a power machine, and the above two power machines can adopt a set of power, that is, a power machine is set, and the power output main shaft of the power machine can be connected to the pressure roller main s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com