Thermoplastic polyurethane/fiber composite soft cloth and preparation method thereof

A thermoplastic polyurethane and fiber composite technology, applied in chemical instruments and methods, synthetic resin layered products, lamination auxiliary operations, etc., can solve the problems of increasing the cost of use, reducing the environmental performance of the composite cloth, increasing the process, etc., to achieve clear lines , Elegant appearance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

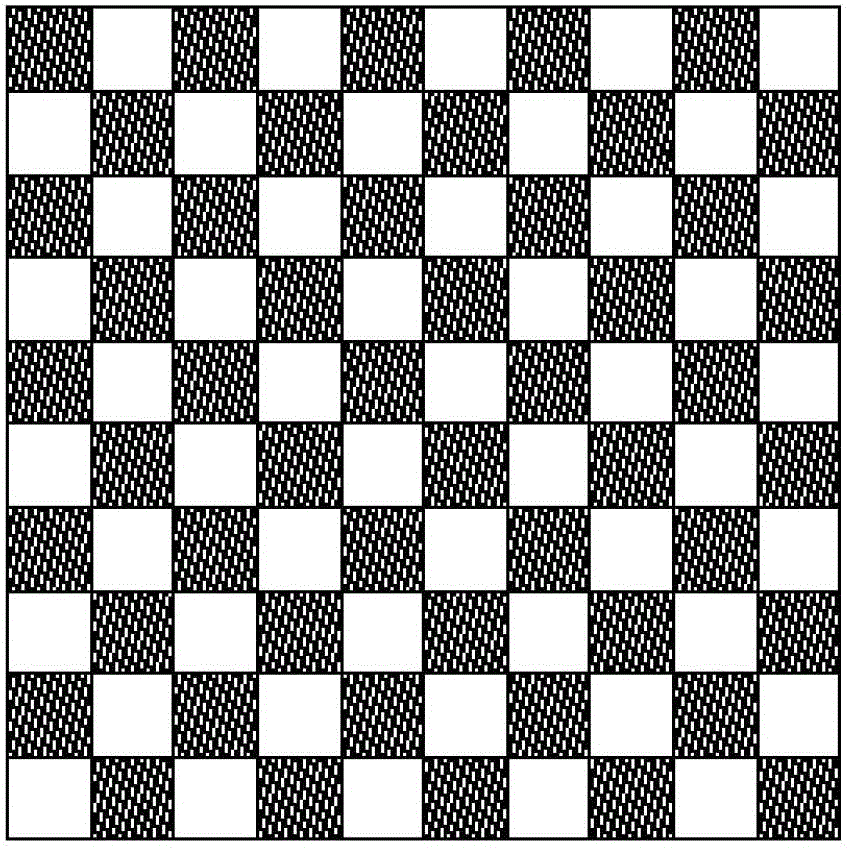

[0076] Install the black continuous glass fiber 3K twill fabric 2 (Shanghai Zhengxingfa International Trade Co., Ltd., thickness 0.25mm) on the creel 1, lead it out in parallel and evenly, and pass it through the tension roller 3 to ensure smoothness, and then pass through the static elimination device 4 Eliminate the static electricity of the glass fiber, and then the continuous fiber enters the preheating oven 5, where the temperature set in the oven (ie heat paste and temperature) is 200°C.

[0077] At the composite part, the screw extruder 6 extrudes a thermoplastic polyurethane film 8 (thickness 0.05 mm) as the upper surface layer, and the screw extruder 7 extrudes a thermoplastic polyurethane film 9 (thickness 0.05 mm) as the lower surface layer, and The continuous 3K twill cloth used as the middle layer is compounded and bonded under the action of a pair of pressing rollers 10 and 11 (with a distance of 0.35mm). The obtained continuous glass fiber 3K twill cloth and the...

Embodiment 2

[0079] Install the single-sided silver continuous glass fiber 1K twill fabric 2 (Shanghai Zhengxingfa International Trade Co., Ltd., thickness 0.18mm) on the creel 1, draw it out in parallel and evenly, and pass it through the tension roller 3 to ensure smoothness, and then pass it through static electricity. The elimination device 4 eliminates the static electricity of the glass fiber, and then the continuous fiber enters the preheating oven 5, where the temperature (ie heat paste and temperature) set in the oven is 170°C.

[0080] At the composite part, the screw extruder 6 extrudes a thermoplastic polyurethane film 8 (thickness 0.01 mm) as the upper surface layer, and the screw extruder 7 extrudes a thermoplastic polyurethane film 9 (thickness 0.01 mm) as the lower surface layer, and The passed continuous 1K twill fabric as the middle layer is compounded and bonded under the action of a pair of pressure rollers 10 and 11 (with a distance of 0.2mm). The obtained continuous g...

Embodiment 3

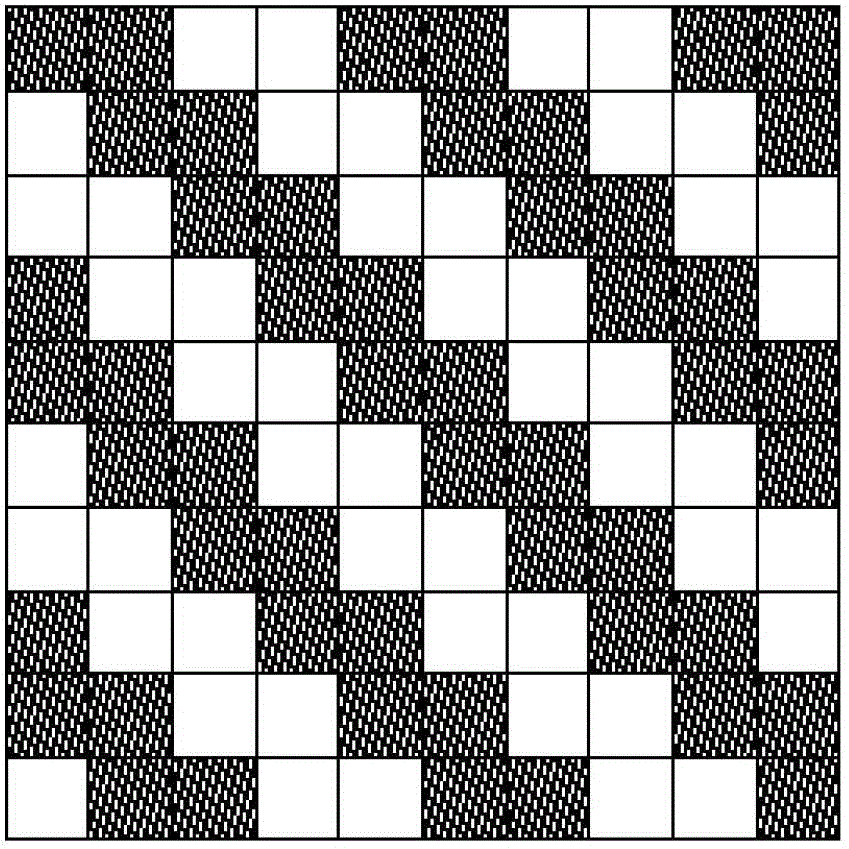

[0082] Install the mixed continuous aramid-carbon fiber mixed fabric 2 (Shanghai Zhengxingfa International Trade Co., Ltd., thickness 0.35mm) on the creel 1, draw it out in parallel and evenly, and pass it through the tension roller 3 to ensure smoothness, and then The static electricity of the glass fiber is eliminated by the static elimination device 4, and then the continuous fiber enters the preheating oven 5, where the temperature set in the oven (ie heat paste and temperature) is 180°C.

[0083] At the composite part, the screw extruder 6 extrudes a thermoplastic polyurethane film 8 (thickness 0.2 mm) as the upper surface layer, and the screw extruder 7 extrudes a thermoplastic polyurethane film 9 (thickness 0.15 mm) as the lower surface layer, and The continuous aramid fiber-carbon fiber blended cloth used as the middle layer is composited and bonded under the action of a pair of pressure rollers 10 and 11 (with a distance of 0.7mm). The obtained continuous aramid-carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com