Flax blended spinning preparation process

A production process and technology of blended yarn, applied in the direction of yarn, bleached products, textiles and papermaking, etc., can solve the problems of no smoothness, hard hand, no luster, etc., and achieve good appearance gloss, simple production process and smooth hand. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

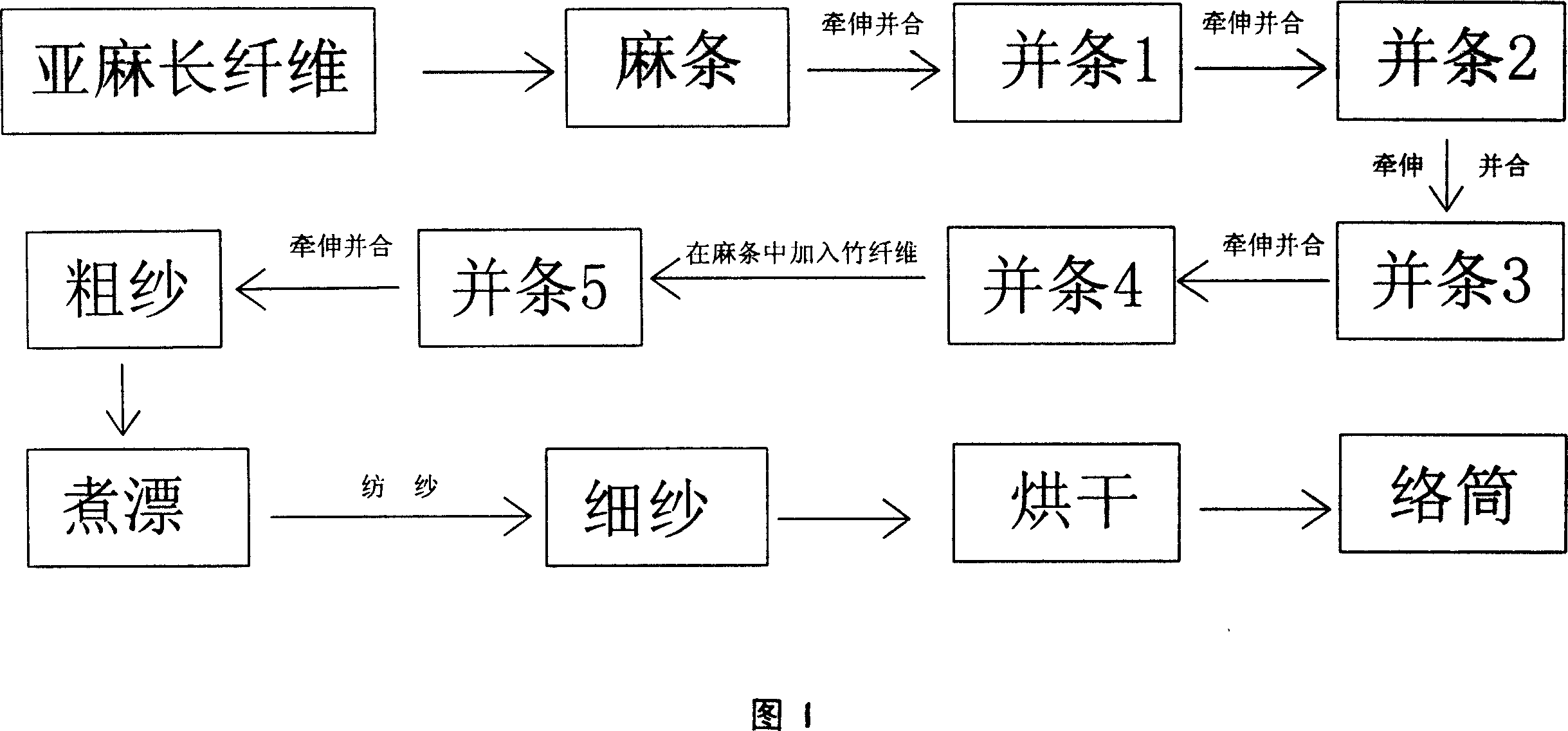

[0009] Referring to Fig. 1, the flax long fibers are combed into slivers of about 18cm, and the slivers are passed through multiple drawing frames: in the first drawing, the second drawing, the third drawing, the fourth In the drawing frame, the flax fiber is continuously drawn and merged, and the bamboo fiber is mixed in the fifth drawing frame. The bamboo fiber is uniform in length, accounting for 8% of the blended yarn mass, and the bamboo fiber and the flax are drawn. Stretched and combined into roving. The roving is scoured and bleached, and the scoured and bleached process includes two processes of sub-bleaching and oxygen bleaching, and the sodium chlorite NaCLO of 1.5g / L is added in water earlier. 2 , the pH value is 2.5, the initial temperature is 30°C, it takes 30 minutes to raise the temperature to 50°C, keep warm for 30 minutes, wash with water, then carry out oxygen bleaching, add 3.5g / L hydrogen peroxide H 2 o 2 , pH value 10, initial temperature: 50°C, take 30...

Embodiment 2

[0011] Referring to Fig. 1, the flax long fibers are combed into slivers of about 18cm, and the slivers are passed through multiple drawing frames: in the first drawing, the second drawing, the third drawing, the fourth In the drawing frame, the flax fiber is continuously drawn and merged, and the bamboo fiber is mixed in the fifth drawing frame. The bamboo fiber is uniform in length and accounts for 40% of the blended yarn mass. Stretched and combined into roving. The roving is scoured and bleached, and the scoured and bleached process includes two processes of sub-bleaching and oxygen bleaching, and the sodium chlorite NaCLO of 1.5g / L is added in water earlier. 2 , the pH value is 3, the initial temperature is 30°C, it takes 30 minutes to raise the temperature to 50°C, keep warm for 40 minutes, wash with water, then carry out oxygen bleaching, add 3.5g / L hydrogen peroxide H 2 o 2 , pH value 10, initial temperature: 50°C, take 30 minutes to raise the temperature to 95°C, ke...

Embodiment 3

[0013] Referring to Fig. 1, the flax long fibers are combed into slivers of about 18cm, and the slivers are passed through multiple drawing frames: in the first drawing, the second drawing, the third drawing, the fourth The flax fiber is continuously drawn and merged in the drawing frame of the first pass, and the bamboo fiber is mixed in the drawing process of the fifth pass. The length of the bamboo fiber is uniform, accounting for 75% of the blended yarn mass percentage. Stretched and combined into roving. The roving is scoured and bleached, and the scoured and bleached process includes two processes of sub-bleaching and oxygen bleaching, and the sodium chlorite NaCLO of 1.5g / L is added in water earlier. 2 , the pH value is 3.5, the initial temperature is 30°C, it takes 30 minutes to raise the temperature to 50°C, keep warm for 25 minutes, wash with water, then carry out oxygen bleaching, add 3.5g / L hydrogen peroxide H 2 o 2 , pH value 10.5, initial temperature: 50°C, tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com