Black masterbatch, nylon 6 fiber and preparation method of black masterbatch and nylon 6 fiber

A black masterbatch, nylon technology, applied in the field of chemical fiber, can solve the problems of affecting the production continuity and yarn quality, many yarns and broken ends, and rising component pressure, so as to achieve excellent appearance and color, save dyeing costs, and avoid environmental problems. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

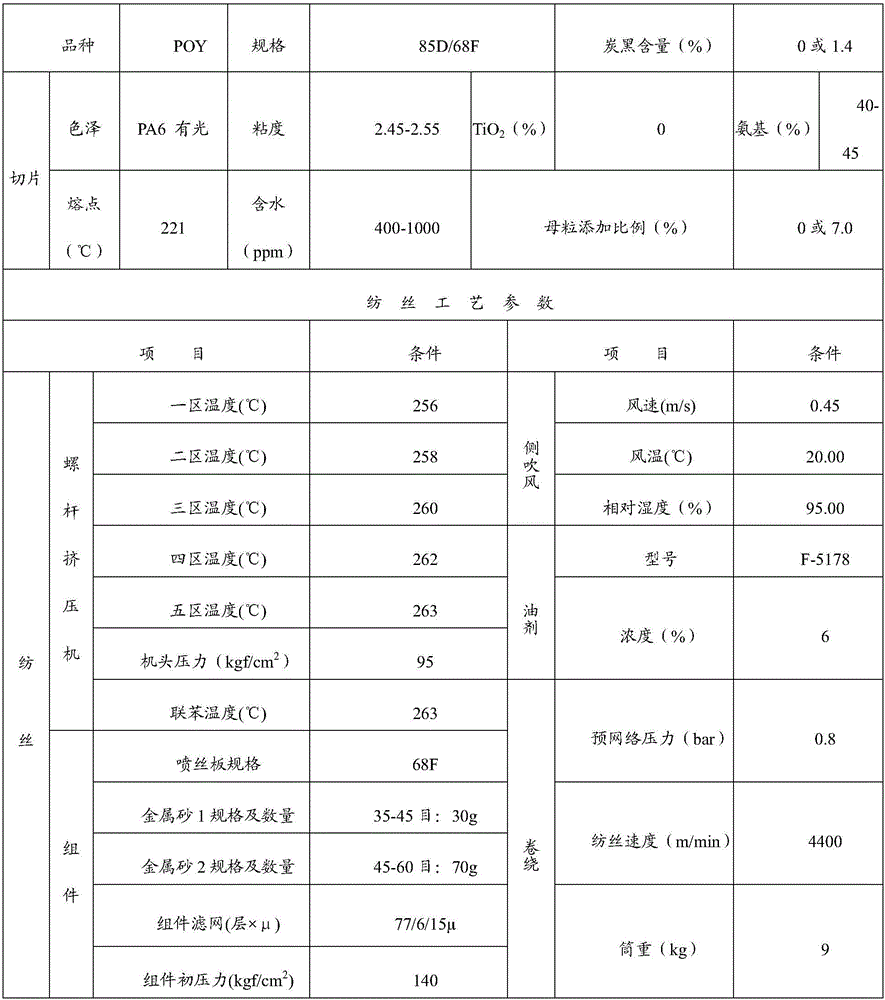

[0022] A method for preparing porous fine denier dope-colored nylon 6 fiber, comprising 20-30 parts by weight of carbon black, 5-15 parts by weight of dispersant, 0.05-0.15 parts by weight of antioxidant and 53-75 parts by weight of polyamide Amide 6 chips are mixed to prepare black masterbatch; then 7-10 parts by weight of black masterbatch and 90-93 parts by weight of polyamide 6 chips are melted, and then mixed and extruded, and the mixed and extruded raw materials are spun The porous fine denier dope-colored nylon 6 pre-oriented yarn is prepared; the porous fine denier dope-colored nylon 6 pre-oriented yarn is drawn and false-twisted to obtain the porous fine-denier dope-colored nylon 6 fiber.

[0023] As can be seen from the foregoing description, the beneficial effects of the present invention are:

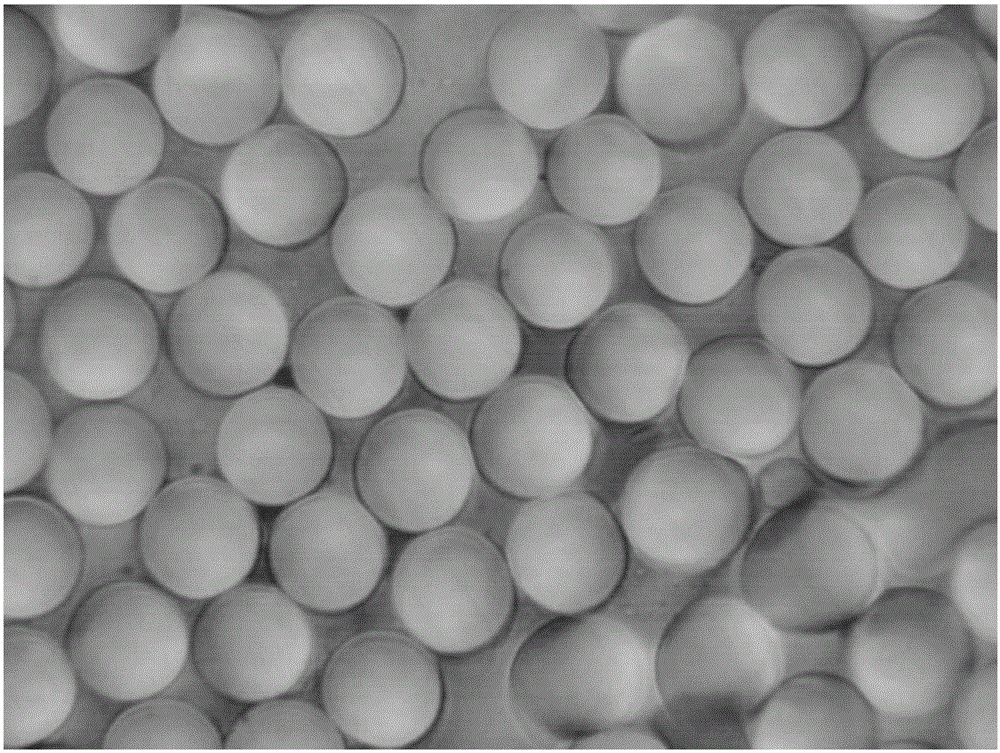

[0024] (1) Through the grinding and filtering of carbon black and the proportioning design of the black masterbatch, the carbon black in the overall black masterbatch is uni...

Embodiment 1

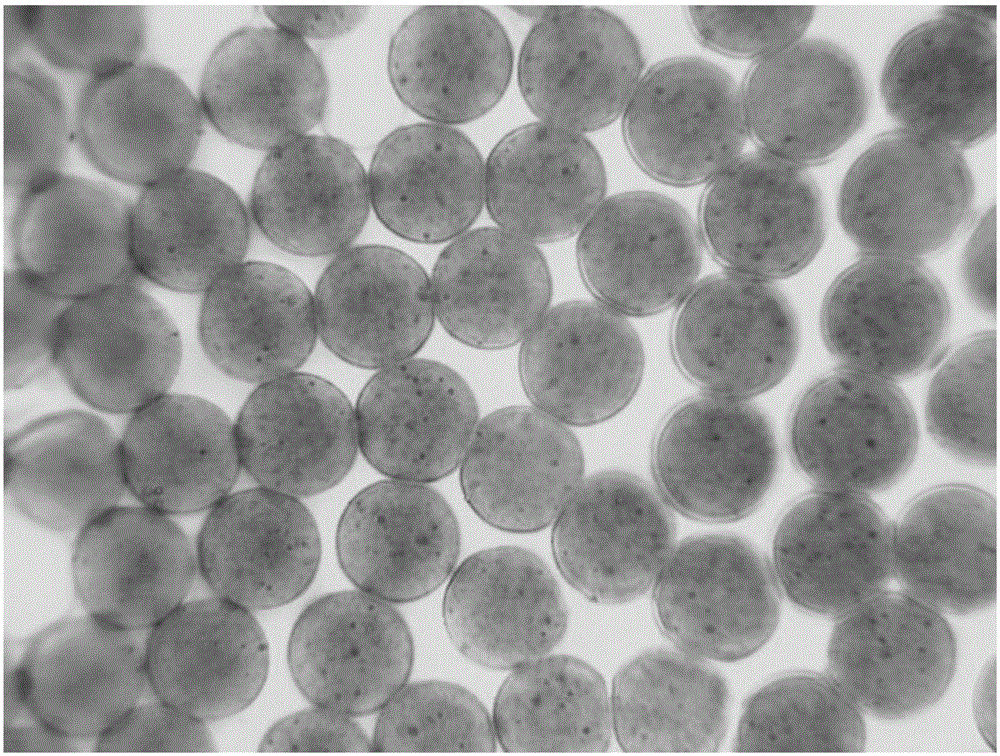

[0049] Please refer to figure 2 , Embodiment 1 of the present invention is:

[0050] A kind of black masterbatch of the present embodiment is prepared from the following raw materials by weight: 20 parts of carbon black, 5 parts of dispersant, 0.05 parts of antioxidant and 74.95 parts of polyamide 6 slices; wherein, the average particle size of carbon black The diameter is 20nm.

[0051] A kind of porous fine denier stock solution colored nylon 6 fiber of the present embodiment is prepared from the following raw materials by weight: 7 parts of black masterbatch and 93 parts of polyamide 6 slices; the black masterbatch is prepared from the following raw materials by weight Components: 20 parts of carbon black, 5 parts of stearic acid dispersant, 0.05 part of pentaerythritol tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate and 74.95 parts of polyamide 6 chips. The average particle size of the carbon black is 20nm. The fineness of the porous fine denier stock solutio...

Embodiment 2

[0053] Please refer to figure 2 , the second embodiment of the present invention is:

[0054] A kind of black masterbatch of the present embodiment is prepared from the following raw materials by weight: 30 parts of carbon black, 15 parts of dispersant, 0.15 parts of antioxidant and 54.85 parts of polyamide 6 chips; wherein, the average particle size of carbon black The diameter is 80nm.

[0055] A kind of porous fine denier stock solution colored nylon 6 fiber of the present embodiment is prepared from the following raw materials by weight: 10 parts of black masterbatch and 90 parts of polyamide 6 slices; the black masterbatch is prepared from the following raw materials by weight Components: 30 parts of carbon black, 15 parts of stearic acid dispersant, 0.15 parts of pentaerythritol tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate and 54.85 parts of polyamide 6 slices. The average particle size of the carbon black is 80nm. The fineness of the porous fine denier ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com