Production process for airflow-spinning stocking yarns

A production process and technology of open-end spinning, applied in knitting, spinning machine, weft knitting and other directions, can solve the problems of rigid feel of open-end spinning and the inability of open-end spinning to be widely recognized by the knitting industry. Processing requirements, the effect of less hairiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

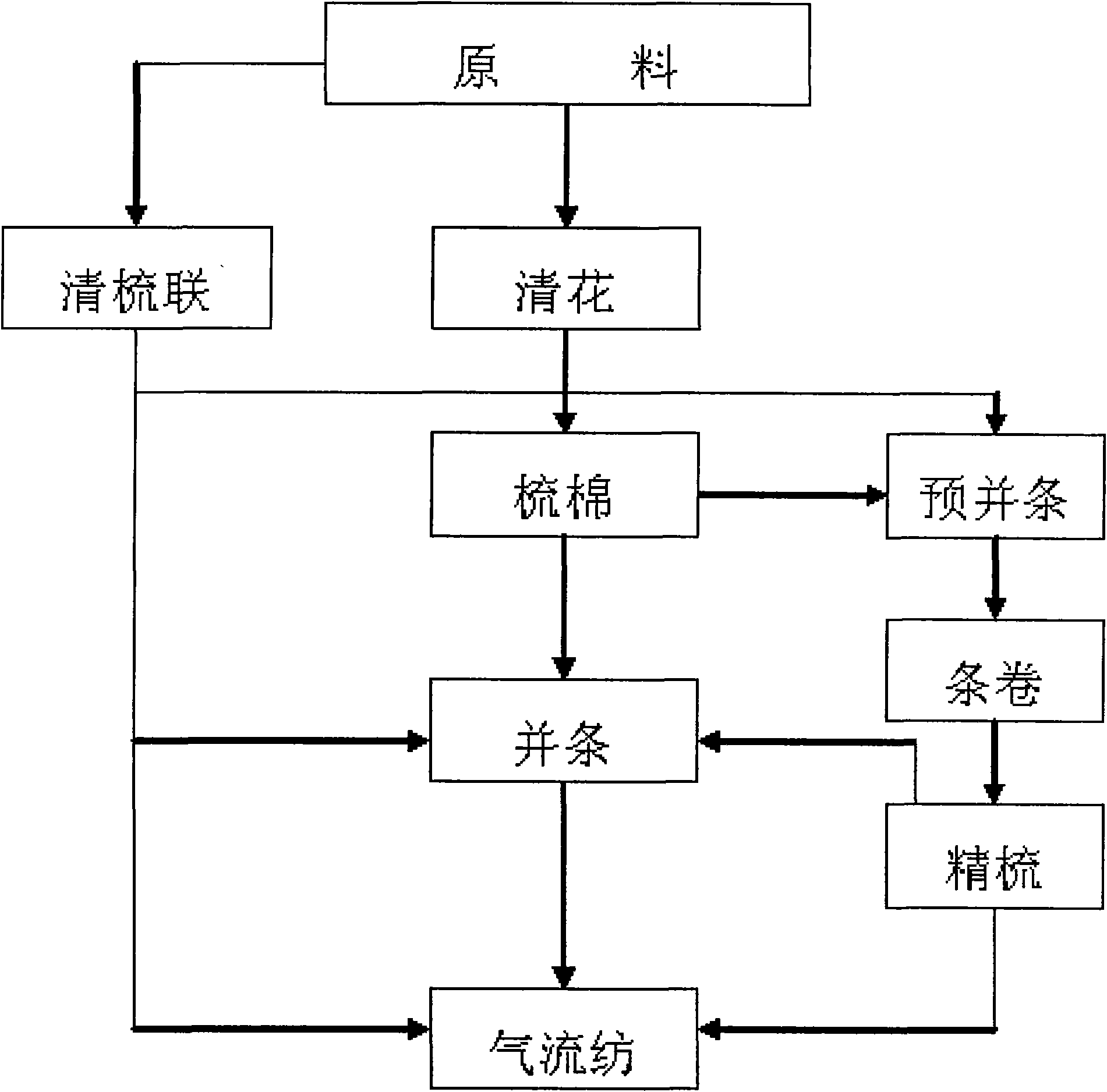

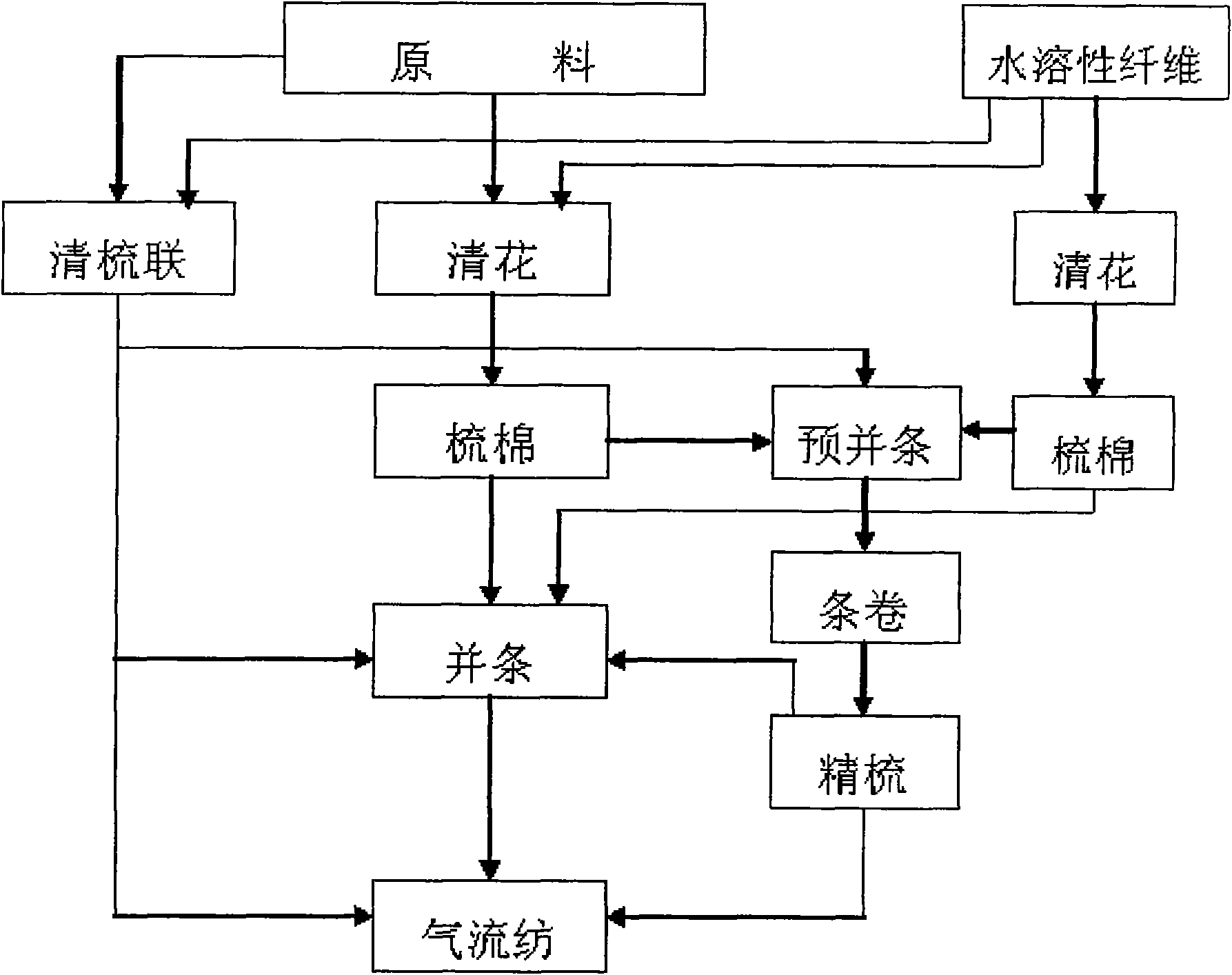

[0018] figure 2 It is a flow chart of the production process of the air spinning knitting yarn described in the present invention.

[0019] Such as figure 2 Shown:

Embodiment 1

[0021] A kind of production technology of air spinning knitting yarn, comprises the following steps:

[0022] In the processing step of cleaning and carding the main fiber, namely cotton, water-soluble fiber, namely water-soluble polyvinyl alcohol (PVA), is added, mixed and processed for cleaning and carding, air spinning, and then knitting to form knitted fabrics. Dissolve the water-soluble fiber therein with hot water, and then dry to obtain a very soft and smooth air-spun knitting yarn, and the dry weight percentage of the above-mentioned water-soluble polyvinyl alcohol in the air-spun knitting yarn is 2.5%.

Embodiment 2

[0024] A kind of production technology of air spinning knitting yarn, comprises the following steps:

[0025] In the cleaning process of the main fiber, that is, hemp, water-soluble fiber, that is, water-soluble polyvinyl alcohol (PVA), is added, and after mixing, it is cleaned, carded, drawn, and then air-spun, and finally formed by knitting. After knitting, hot water is used to dissolve the water-soluble fiber therein, and after drying, a very soft and smooth air-spun knitting yarn is obtained, and the dry weight percentage of the above-mentioned water-soluble polyvinyl alcohol in the air-spun knitting yarn is 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com