Tunnel chamber for drying

A drying room and tunnel-type technology, which is applied in local agitation dryers, static material dryers, drying, etc., can solve the problems that are not conducive to the evaporation and drying of materials, the inability of continuous in and out of materials, and the decline in material quality. Drying time, shortened drying time, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

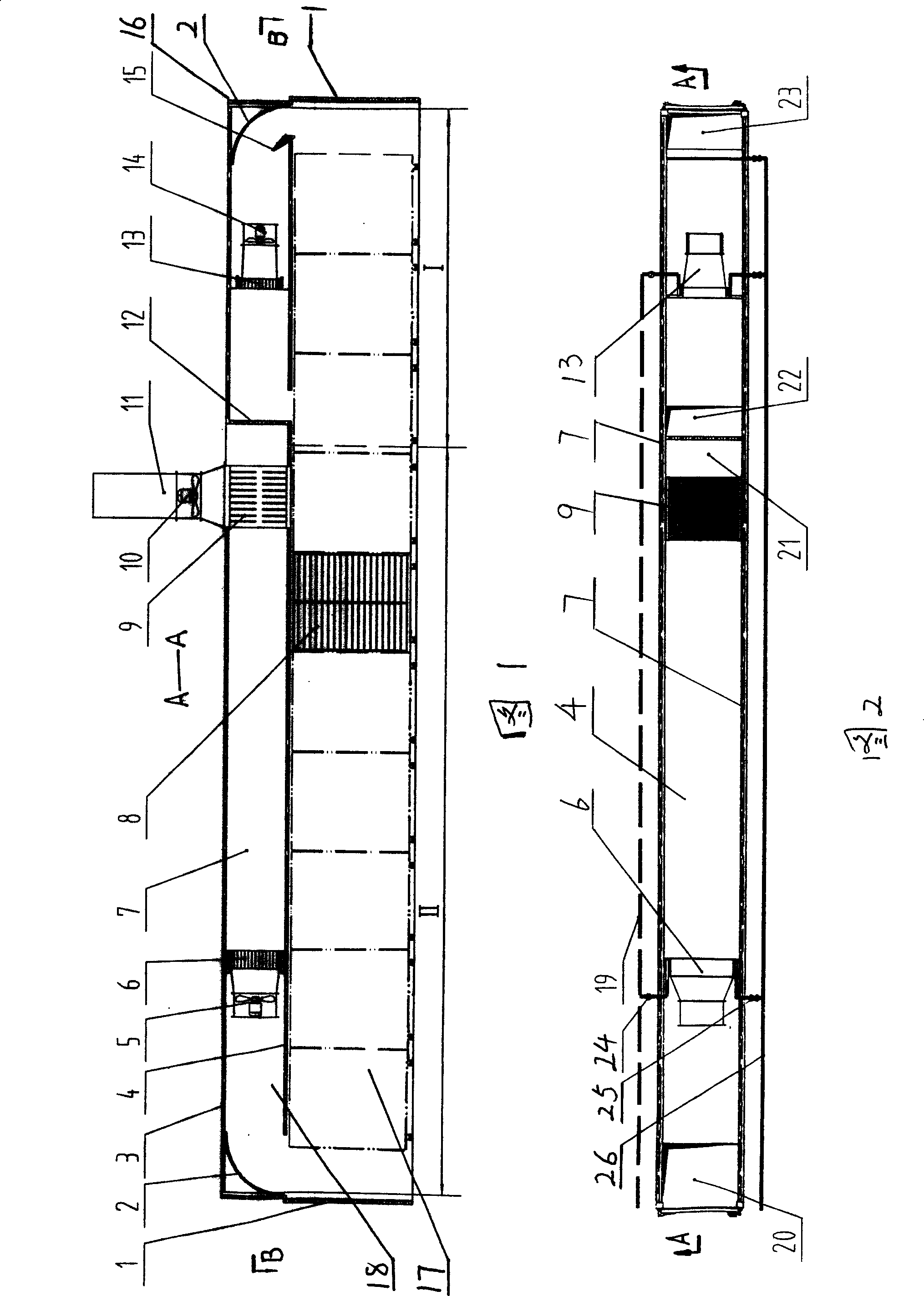

[0011] The present invention will be further described in detail below in conjunction with specific implementation examples.

[0012] The present invention is in the drying chamber 16 that is made up of drying chamber door 1, drying chamber top board 3, drying chamber side plate 7, and middle board 4 is housed, and middle board 4 divides drying chamber 16 into drying chamber 17 (middle board 4 and the ground) and the air duct 18 (between the top plate 3 and the middle plate 4 of the drying chamber). A partition 12 is installed in the air duct 18, and the partition 12 divides the air duct 18 into two parts, front and rear. An air preheater 9, a main heat exchanger 6 and a main fan 5 are provided, and an auxiliary heat exchanger 13, an auxiliary fan 14 and a steam nozzle 15 are arranged in the rear air duct. The middle plate is provided with a dry hot air outlet 20, a heating return air outlet 22, and a heating air outlet 23. The partition 12 is located in the air duct 18 close ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com