Sword blank hot-rolling former and hot-rolling manufacturing method using same

A technology of hot rolling and forming machine, applied in the application, sickle, cutting knife and other directions, can solve the problems of high hardness requirements of mechanical equipment, low production efficiency, difficult to control the quality of sword products, etc., to achieve high continuous production efficiency and degree of automation Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

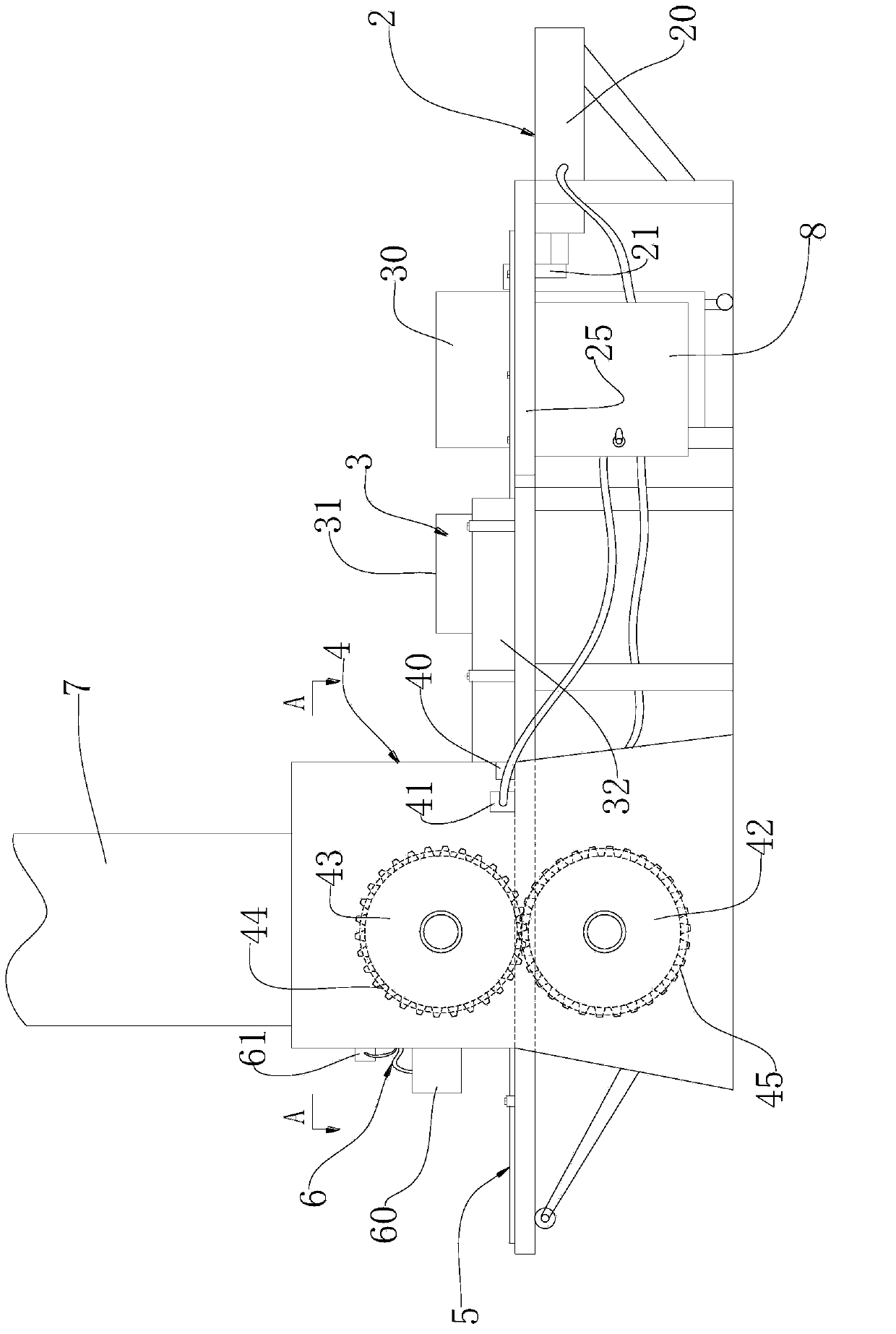

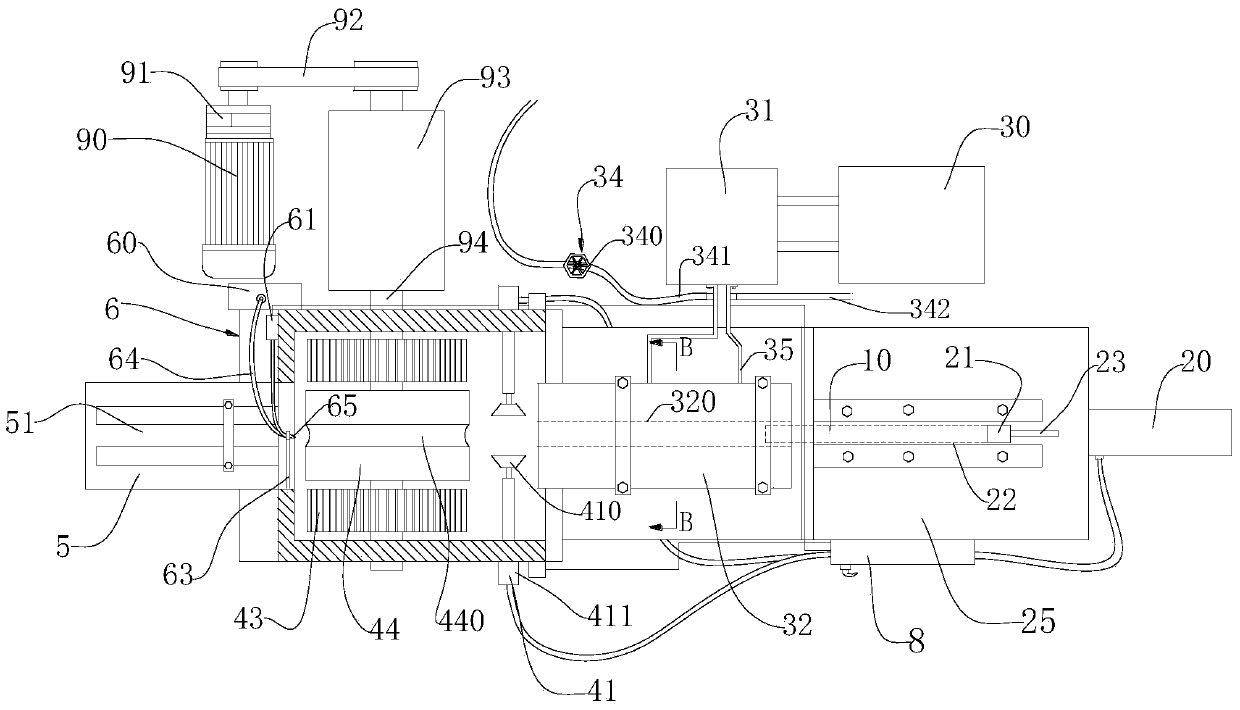

[0032] Such as figure 1 , figure 2 and image 3As shown, a hot rolling forming machine for a sword blank, the hot rolling forming machine for a sword blank includes a feeding mechanism 2, a high-frequency heating system 3, a rolling machine 4, a discharge platform 5, and a demoulding oil cooling liquid Spray device 6, suction pipe 7 and controller 8. Both the feeding mechanism 2 and the high-frequency heating system 3 are on one side of the rolling machine 4, the discharge platform 5 is on the opposite side of the rolling machine 4, and the high-frequency heating system 3 is on the feeding mechanism 2 and the rolling machine. between presses 4. Rolling machine 4 top is provided with opening, and suction pipe 7 is connected on rolling machine 4 tops, and suction pipe 7 lower ends are correspondingly connected on the opening.

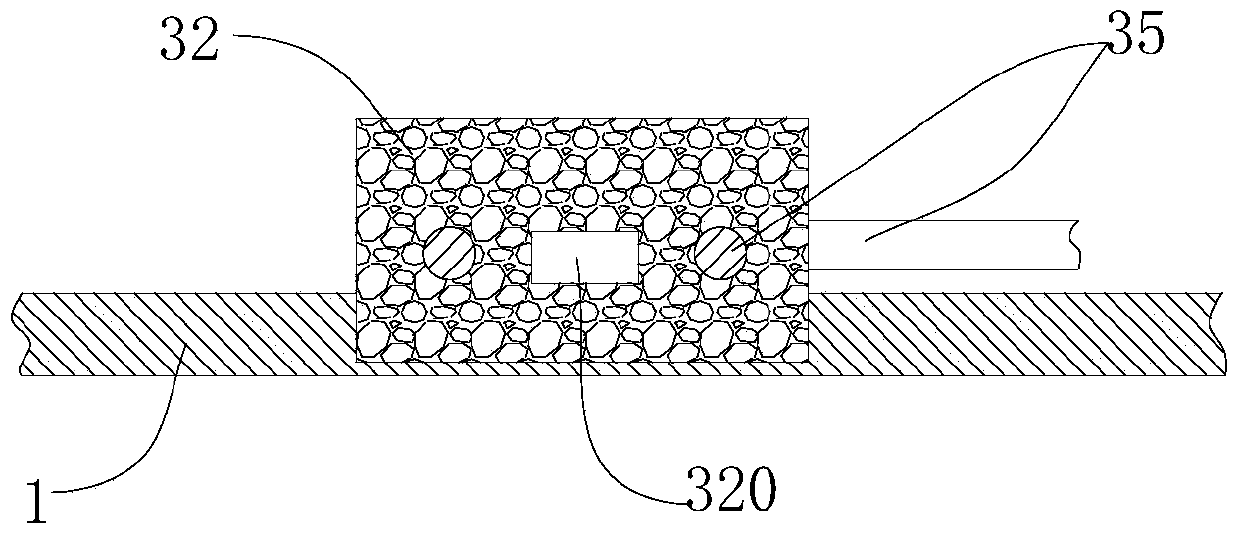

[0033] Such as figure 2 , image 3 and Figure 4 As shown, the above-mentioned high-frequency heating system 3 includes an induction coil tube 3...

Embodiment 2

[0051] The only difference from Example 1 is that the high-temperature cement material in the high-temperature cement block 32 is made of the following components and proportions according to the raw materials in parts by weight: 100 parts of cement, 43 parts of water, 26 parts of tricalcium aluminate, poly 9 parts of ester fiber, 7 parts of retarder, 24 parts of polypropylene fiber. All the other repeat Example 1.

Embodiment 3

[0053] The only difference from Example 1 is that the high-temperature cement material in the high-temperature cement block 32 is made of the following components and proportions according to the raw materials in parts by weight: 100 parts of cement, 41 parts of water, 21 parts of tricalcium aluminate, poly 6 parts of ester fiber, 7 parts of retarder, 21 parts of polypropylene fiber. All the other repeat Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com