Synthesis gas liquification catalyst and catalyzing method thereof, beds and preparation method

A catalyst and synthesis gas technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems such as complex reactor structure, difficult maintenance, increased process costs, etc., to reduce equipment investment and production costs As well as the demand for external energy input, improving mass transfer and heat transfer efficiency, and simplifying the effect of separation and purification steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

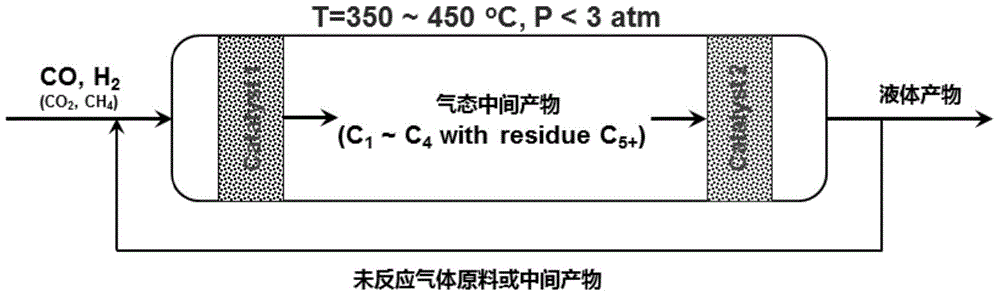

Method used

Image

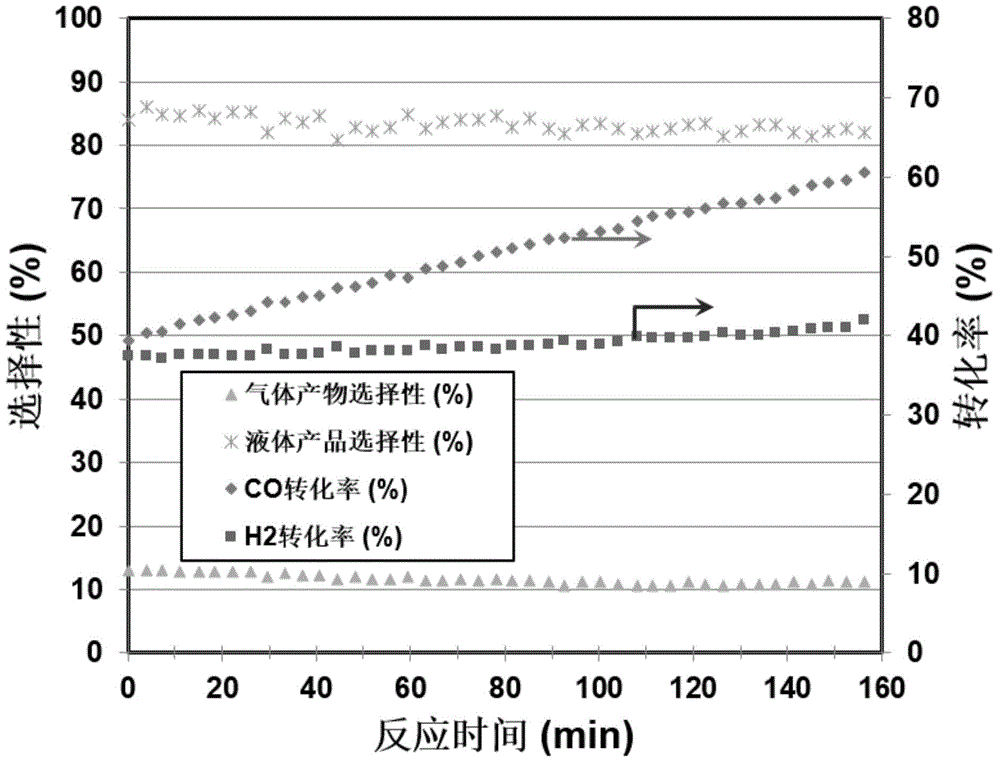

Examples

Embodiment 1

[0030] 1, synthetic by 5wt.%K / 52wt.%MnO 2 -48wt.% Fe 2 o 3 Primary catalyst composed of:

[0031] 1) Weigh 6.175g manganese nitrate (Mn 2 (NO 3 ) 3 ·xH 2 O) and 13.94g iron nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O), and it is dissolved in 100mL deionized water to make A solution;

[0032] 2) Weigh a certain amount of sodium carbonate (Na 2 CO 3 ), and dissolve it into an appropriate amount of deionized water to obtain a concentration of B solution that is 0.5M;

[0033] 3) Add solution B to solution A drop by drop, and keep stirring until the pH is 10;

[0034] 4) stirring the slurry obtained in step 3) at the desired pH for an additional 0.5 hours;

[0035] 5) aging the liquid-solid mixture obtained in step 4) in a beaker;

[0036] 6) Add deionized water to the aged mixture, then perform vacuum filtration or centrifugation, and wash repeatedly to remove sodium ions until the filtrate is neutral (i.e. pH is 7);

[0037] 7) put the paste obtained in step 6) into a...

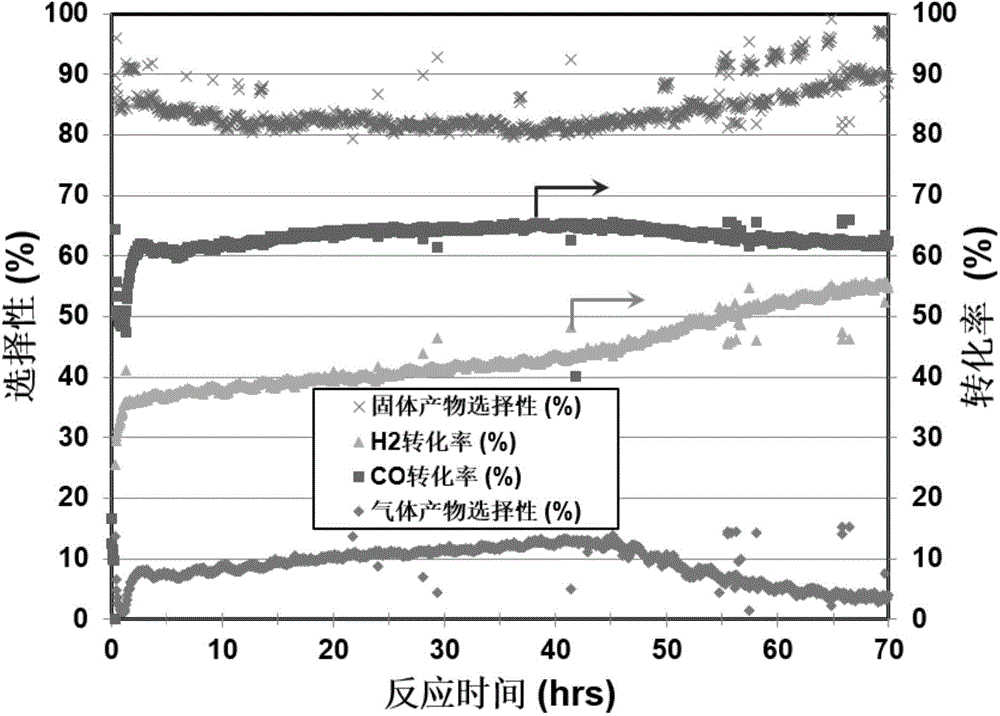

Embodiment 2

[0064] 1, synthetic by 5wt.%K / 52wt.%MnO 2 -48wt.% Fe 2 o 3 Primary catalyst composed of:

[0065] With embodiment 1.

[0066] II. Synthesis of a secondary catalyst consisting of 1wt.%Ag / ZSM-5:

[0067] 1) Weigh 0.09g silver nitrate (AgNO 3 ) and dissolved in 6mL deionized water to make a transparent B solution;

[0068] 2) Carefully dip solution B into 5gHZSM-5(SiO 2 with Al 2 o 3 The molar ratio is 280) the surface of the carrier (pay attention to the amount of B solution added each time, and ensure that the carrier is not over-wetted);

[0069] 3) Put the impregnated sample into a drying oven and set it at 110 degrees Celsius to dry for 12 hours;

[0070] 4) Repeat steps 13) and 14) until all B solutions are impregnated onto the surface of the carrier;

[0071] 5) The impregnated Ag / ZSM-5 catalyst was calcined in the air at 600 degrees Celsius for 2 hours, and then naturally cooled to room temperature to obtain the desired catalyst, which was collected for use.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com