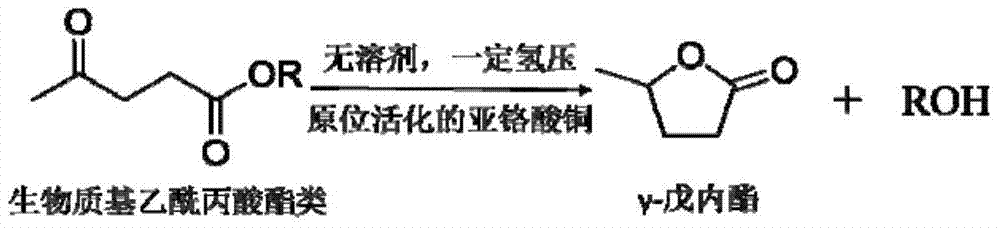

Method for preparing gamma-valerolactone by levulinic acid ester without solvents

A technology of levulinic acid ester and valerolactone, applied in the direction of organic chemistry, etc., can solve the problem of high energy consumption, and achieve the effects of simplified separation and purification steps, excellent cycle performance, and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 0.1 g of copper chromite without hydrogenation pretreatment to 20 g of ethyl levulinate raw material liquid as a catalyst, reduce in situ at 225 °C and 4 MPa hydrogen pressure and react for 4 h, then filter under reduced pressure to obtain colorless Clear liquid. After the ethanol was distilled off under reduced pressure, the crude product of γ-valerolactone was obtained with a yield of 57.5%.

Embodiment 2

[0023] Add 0.2 g of copper chromite without hydrogenation pretreatment to 20 g of butyl levulinate raw material liquid as a catalyst, reduce in situ at 250 °C and 2 MPa hydrogen pressure and react for 4 h, then filter under reduced pressure to obtain colorless Clear liquid. After the ethanol was distilled off under reduced pressure, the crude product of γ-valerolactone was obtained with a yield of 46.9%.

Embodiment 3

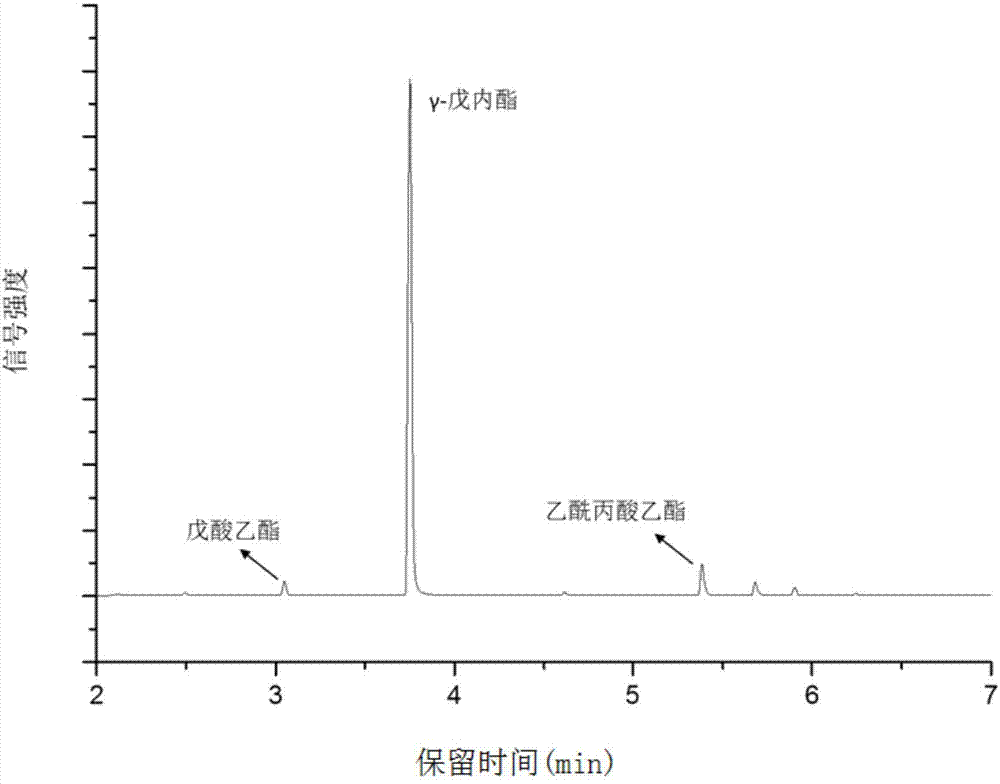

[0025] Add 0.2 g of copper chromite without hydrogenation pretreatment to 20 g of methyl levulinate raw material liquid as a catalyst, reduce in situ at 275 °C and 4 MPa hydrogen pressure and react for 4 h, then filter under reduced pressure to obtain colorless Clear liquid. After the ethanol was removed by distillation under reduced pressure, the crude product of gamma-valerolactone was obtained, and the productive rate was 85.6% (as figure 1 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com