Preparation method of agarose immune magnetic microspheres and applications thereof

A magnetic microsphere and agarose technology, which is applied in the preparation method of peptide, microsphere preparation, anti-animal/human immunoglobulin, etc., can solve the complex process of monoclonal antibody, highly toxic coupling agent, high cost, etc. problems, achieve the effects of reduced pretreatment time, mild separation and purification conditions, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

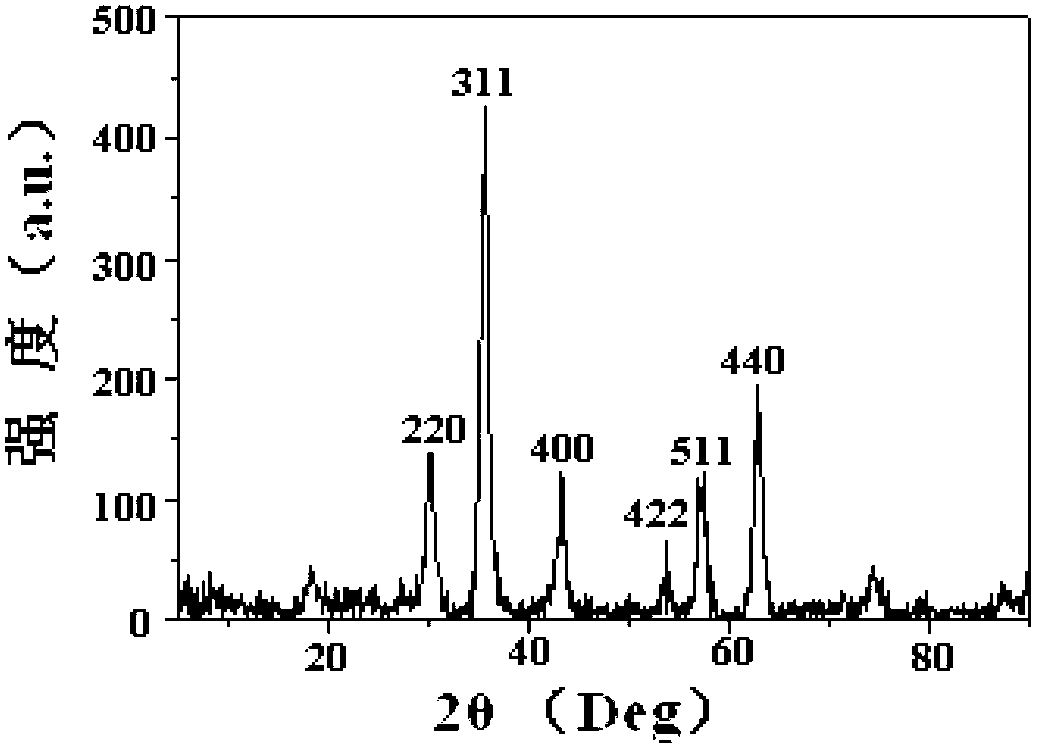

Image

Examples

specific Embodiment approach 1

[0028] Specific embodiment one: the preparation method of a kind of agarose immunomagnetic microsphere of the present embodiment is to carry out according to the following steps:

[0029] 1. Take 10-15g of FeCl3·6H 2 O and 30-50g of sodium oleate are dissolved in a mixed solvent, heated to 60-80°C, and kept for 4-6 hours. After the reaction is completed, take the upper organic solvent and wash it with distilled water three times, and remove the organic solvent by rotary evaporation to obtain ferric oleate. Precursor; wherein, the mixed solvent is formed by mixing ethanol, distilled water and n-hexane in a volume ratio of 60-80:40-60:120-140;

[0030] 2. At room temperature, mix 30-40g of oleic acid, 5-8g of the iron oleate precursor obtained in step 1, and 100-200g of octadecene, and then heat it to 320°C at a rate of 3-5°C per minute. ~340℃, keep warm for 20~50min, then naturally cool to room temperature, add 400~600mL of absolute ethanol, and centrifuge at 3000~5000rpm for ...

specific Embodiment approach 2

[0041] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, heat to 70° C. and keep warm for 4 hours. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0042] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that: in step 1, the mixed solvent is formed by mixing ethanol, distilled water and n-hexane in a volume ratio of 80:60:140. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com