a sand making machine

A sand making machine and casing technology, which is applied in the direction of grain processing, etc., can solve the problems of reducing the working efficiency of the sand making machine, exposing the river bottom full of holes, destroying the natural environment, etc., and achieving simple structure, reliable structure, and convenient dredging The effect of blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

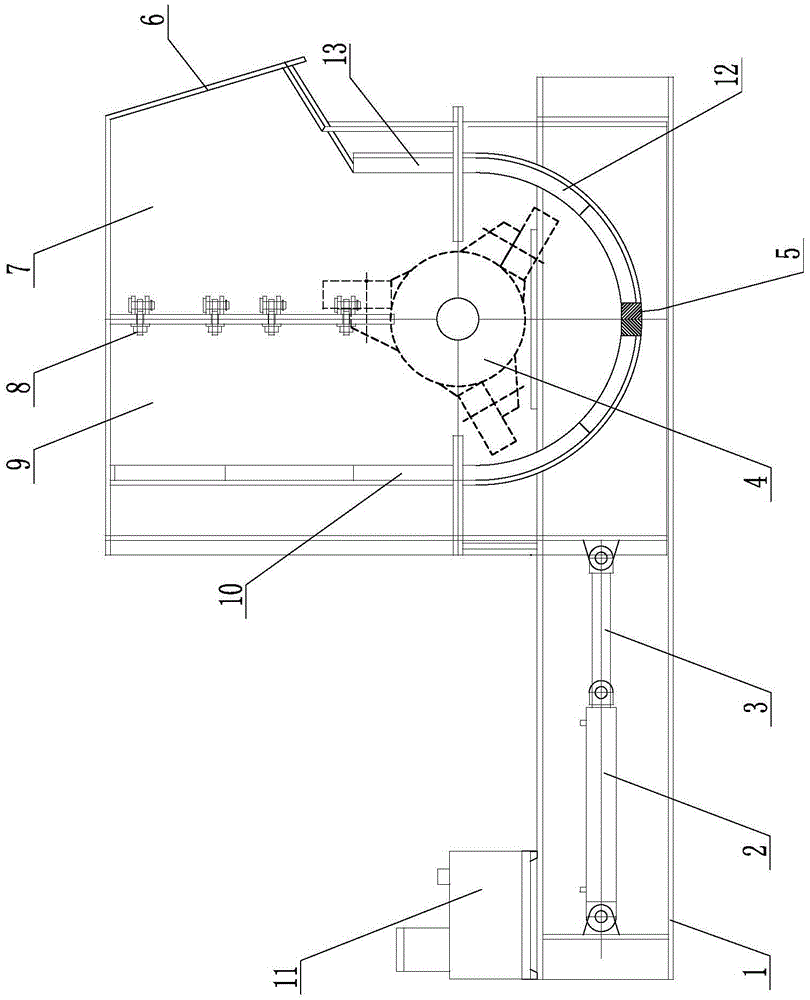

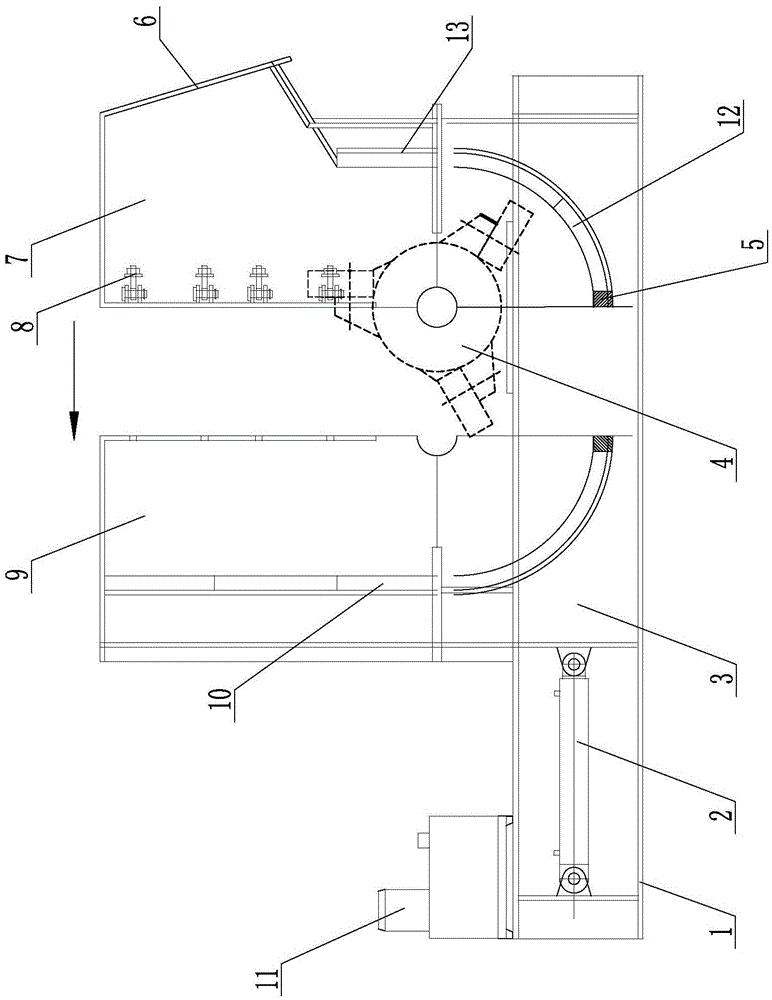

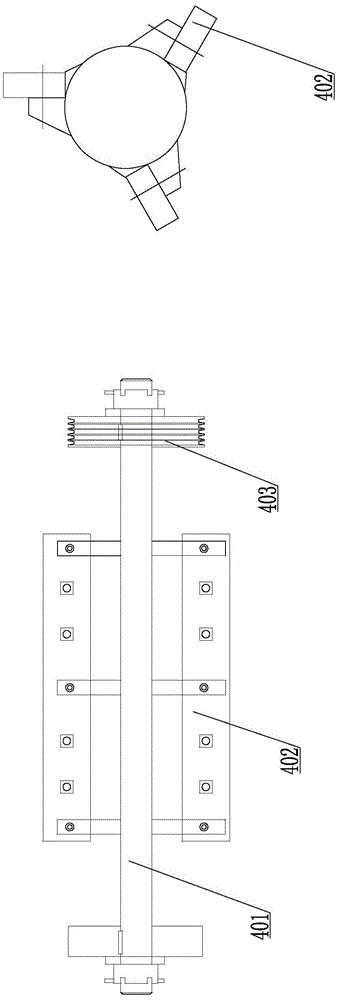

[0017] like Figure 1-Figure 5 As shown, the sand making machine of this embodiment includes a base 1 and a casing, the casing is provided with a feeding port 6, the casing is provided with a rotor body 4, and the rotor body 4 includes a rotating shaft 401 and a At one end of the rotating shaft 401 is a pulley 403 driven by a motor for driving the rotating shaft 401 to rotate. Several plate hammers 402 are evenly distributed on the rotor body 4. The casing includes a first casing 9 and a second casing 7. The first shell 7 and the second shell 9 are opposite to each other, and a lower grate plate 12 is fixed to the bottom of the first shell 9 and the second shell 7 , and the outer sides of the two lower grate plates 12 are fixed. A front grate plate 13 and a rear grate plate 10 are fixedly connected respectively, the front grate plate 13 is arranged below the feed port 6, and the lower grate plate 12 and the rear grate plate 10 are evenly distributed with a number of grate hole...

Embodiment 2

[0024] In the sand making machine of this embodiment, the mandrel 3 is connected to the second casing 7, and other structures and usages are the same as those of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com