A fluid circuit system suitable for multi-cabin spacecraft

A technology of fluid circuit system and spacecraft, which is applied in space navigation equipment, space vehicle, space vehicle docking device, etc. It can solve the problem of difficult layout, inability to eliminate the influence of satellite attitude, leakage of working fluid into space and Other problems on the cabin body, to solve the effect of excessive insertion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the accompanying drawings and examples.

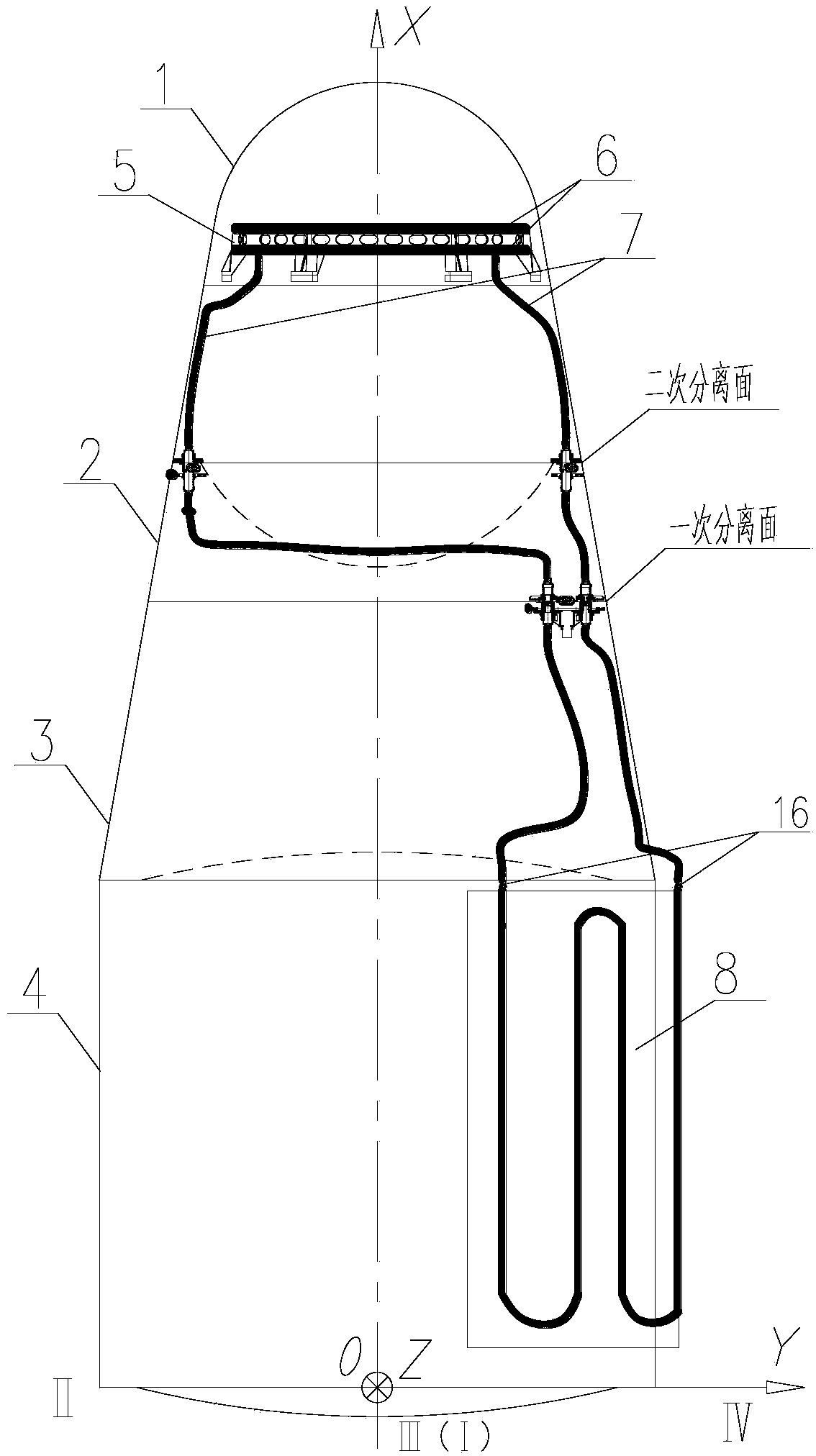

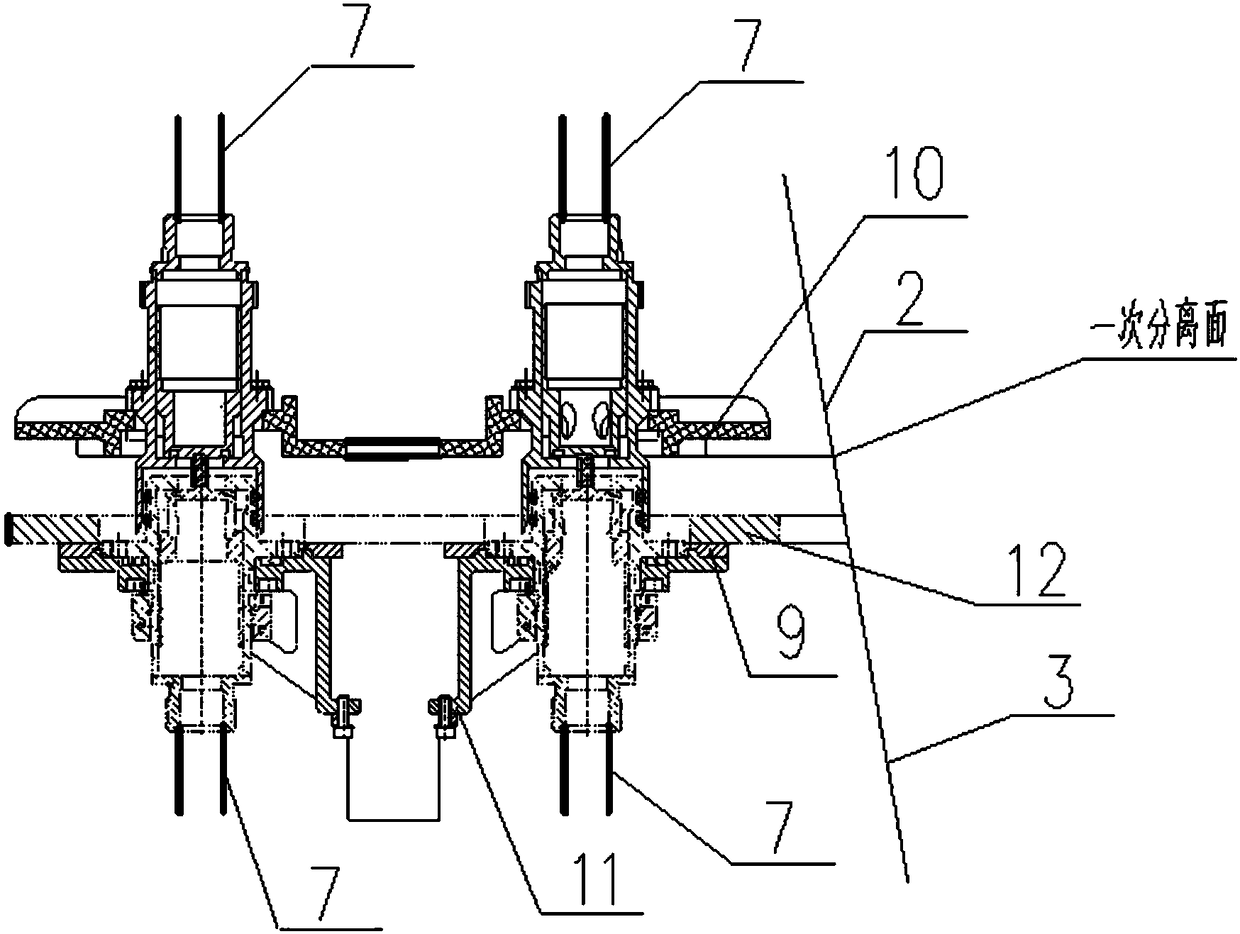

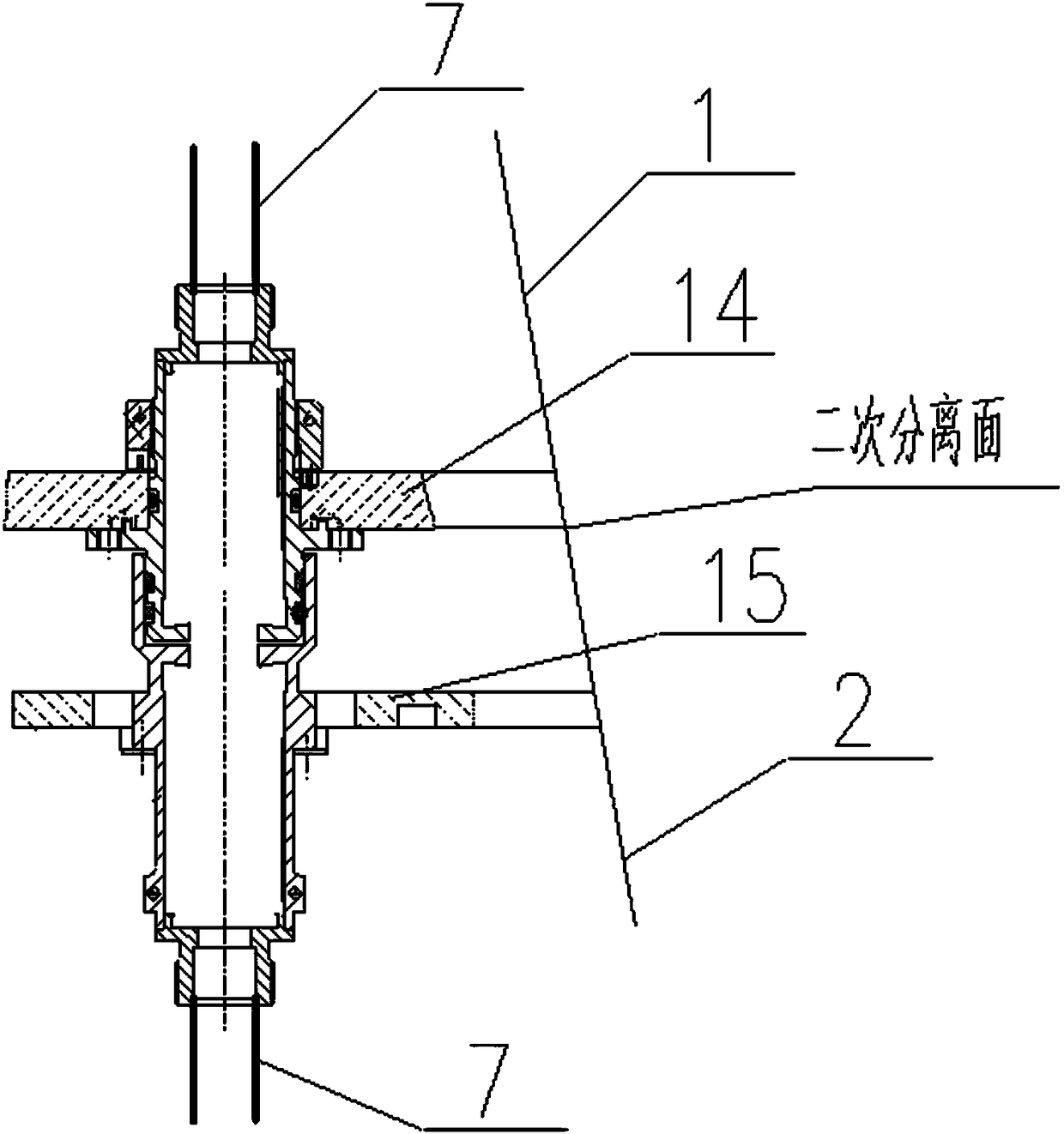

[0038] The present invention provides a fluid circuit system suitable for multi-chamber spacecraft, see attached Figure 1-4 , including: cold plate 6, fluid pipeline 7, radiator 8, four fluid circuit breakers, separation device 11 and detachable joint 16;

[0039] Its peripheral equipment is: recovery module 1, braking module 2, service module 3, sealing module 4 and instrument panel 5; the recovery module 1, braking module 2, service module 3 and sealing module 4 are docked in sequence to form the spacecraft External structure; the instrument panel 5 is installed in the recovery cabin 1, and its upper and lower surfaces are equipped with equipment in the cabin;

[0040] More than two circles of coaxial annular holes are processed in the cold plate 6, and more than two circles of annular holes communicate with each other;

[0041] The liquid circuit bre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com