Method for automatically discharging and deblocking material from material barrel

A technology of automatic material discharge and barrel, which is applied in the direction of emptying containers, loading/unloading, and bottle filling. The effect of discharging efficiency and facilitating clutch operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

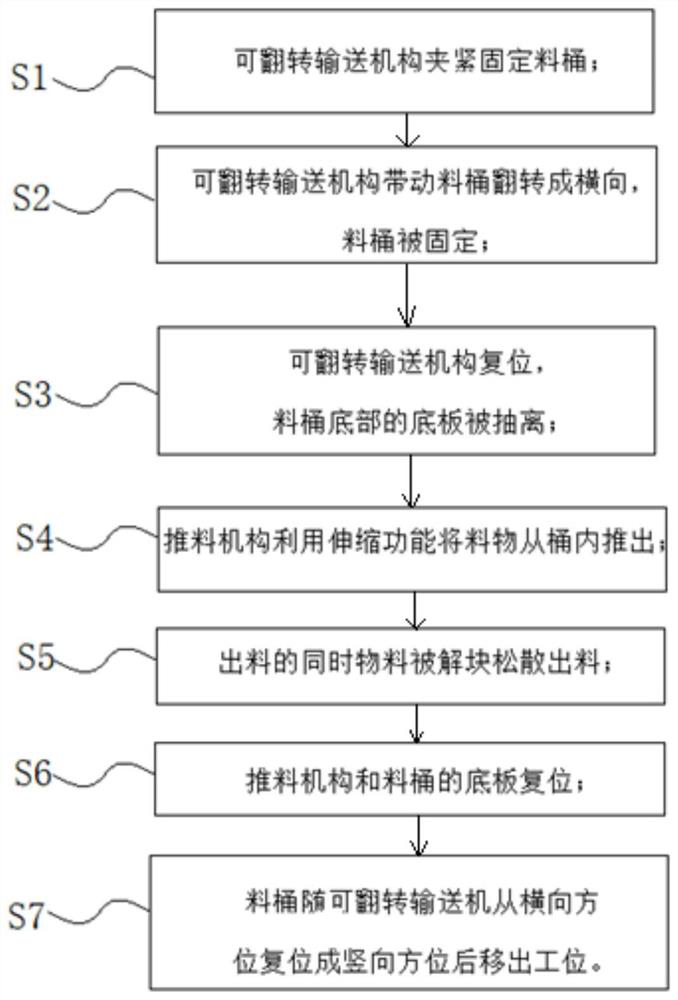

[0015] Embodiment 1: a method for automatically discharging and deblocking materials from a material barrel,

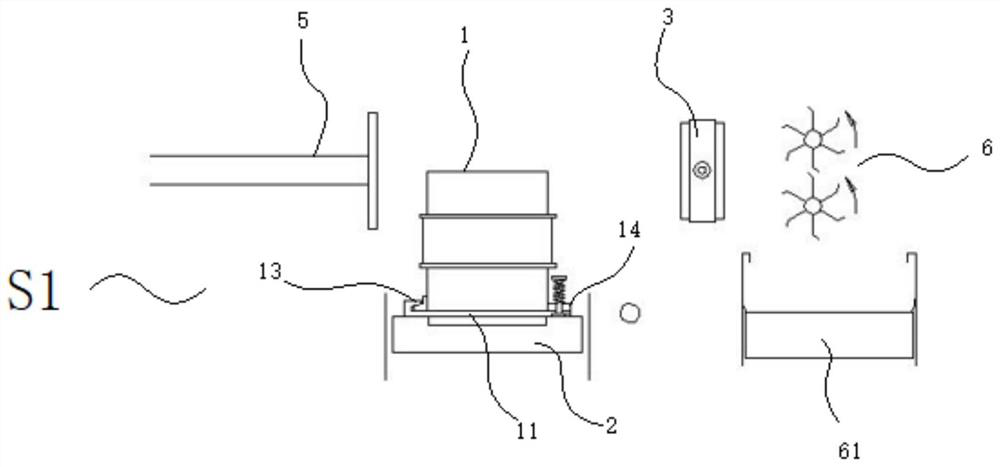

[0016] Step S1, the movable floor at the bottom of the barrel and the barrel body are kept in a fixed state for conveying, and after entering the station, drive into the reversible and reversible conveying mechanism to stop, and the reversible conveying mechanism clamps and fixes the barrel;

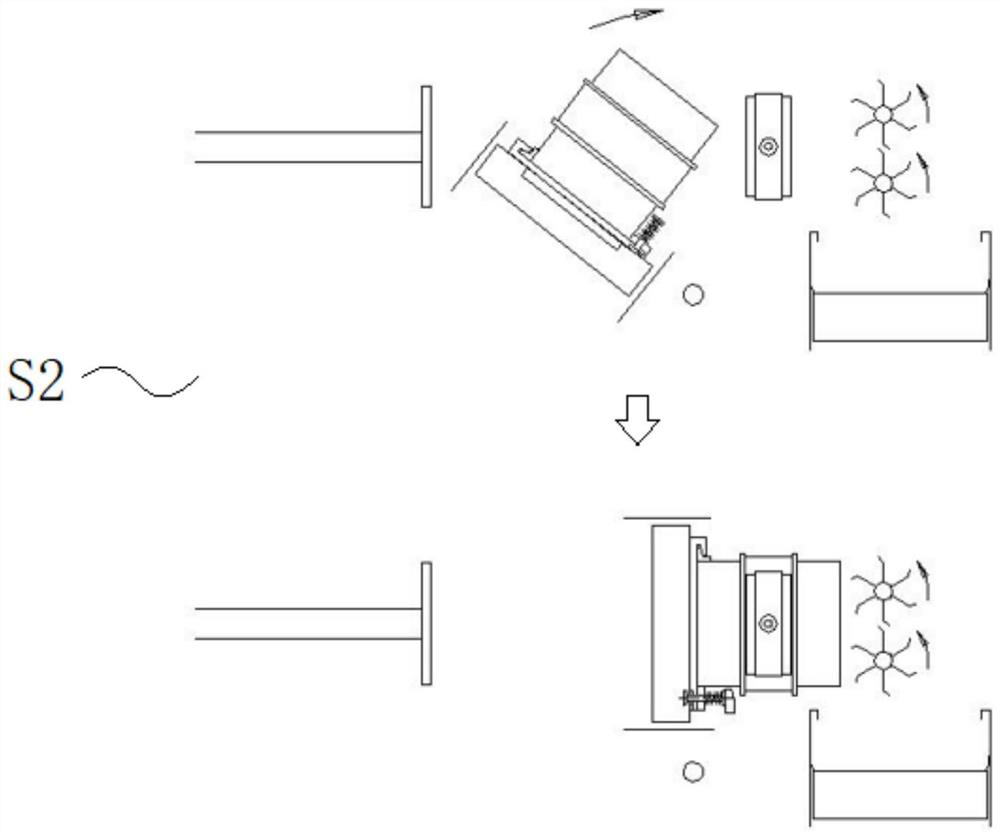

[0017] Step S2, the reversible conveying mechanism is turned over and rotated along the rotation axis, driving the material barrel to rotate in a horizontal direction, the material barrel is fixed by the clamping mechanism, and at the same time the movable bottom plate is released and the fixed state of the barrel body is a loose state;

[0018] Step S3, the reversible conveying mechanism loosens the clamping of the material barrel and rotates to reset, and the bottom plate pulling mechanism located above the material barrel clamps the movable bottom plate and pulls it upwards, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com