Robot for detecting cotter pin of control rod guide tube and locating method

A cotter pin and guide cylinder technology, which is applied in nuclear reactor monitoring, reactors, nuclear power generation, etc., can solve the problems of difficulty in observing and locating the end face of cotter pins, and achieve the effects of repeatability, precise positioning, and overcoming the influence of visual space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

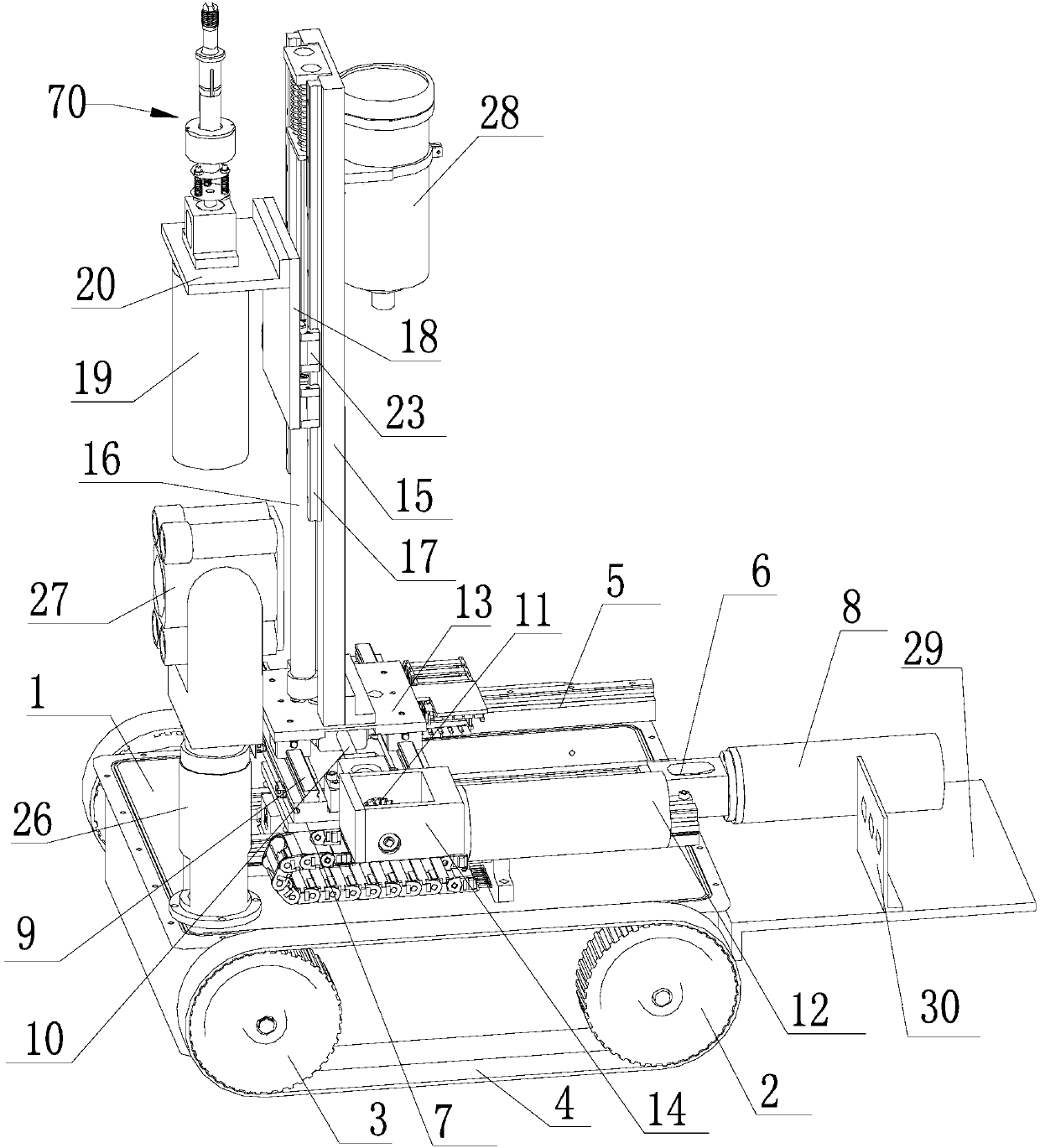

[0027] The present invention will be described in detail below in conjunction with the embodiments shown in the drawings:

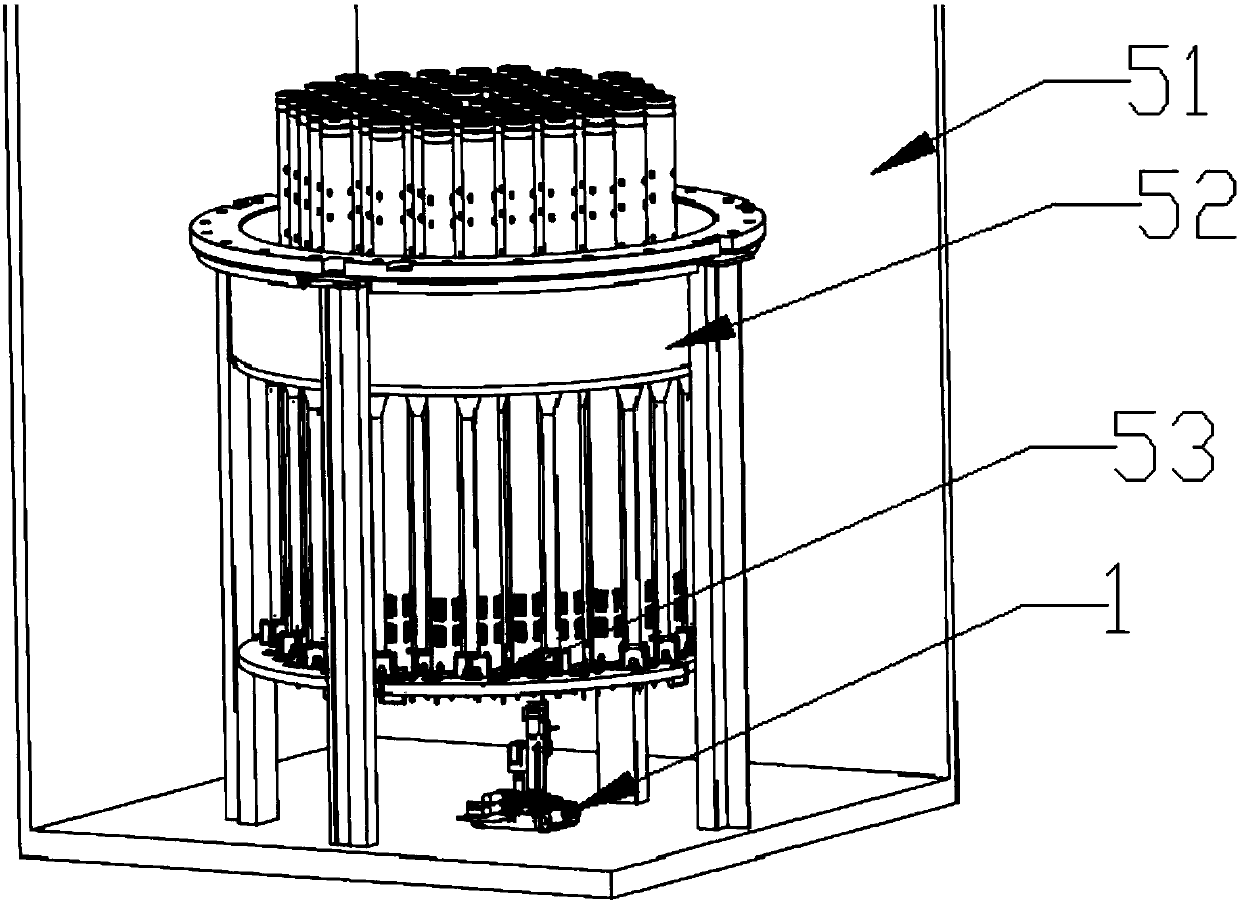

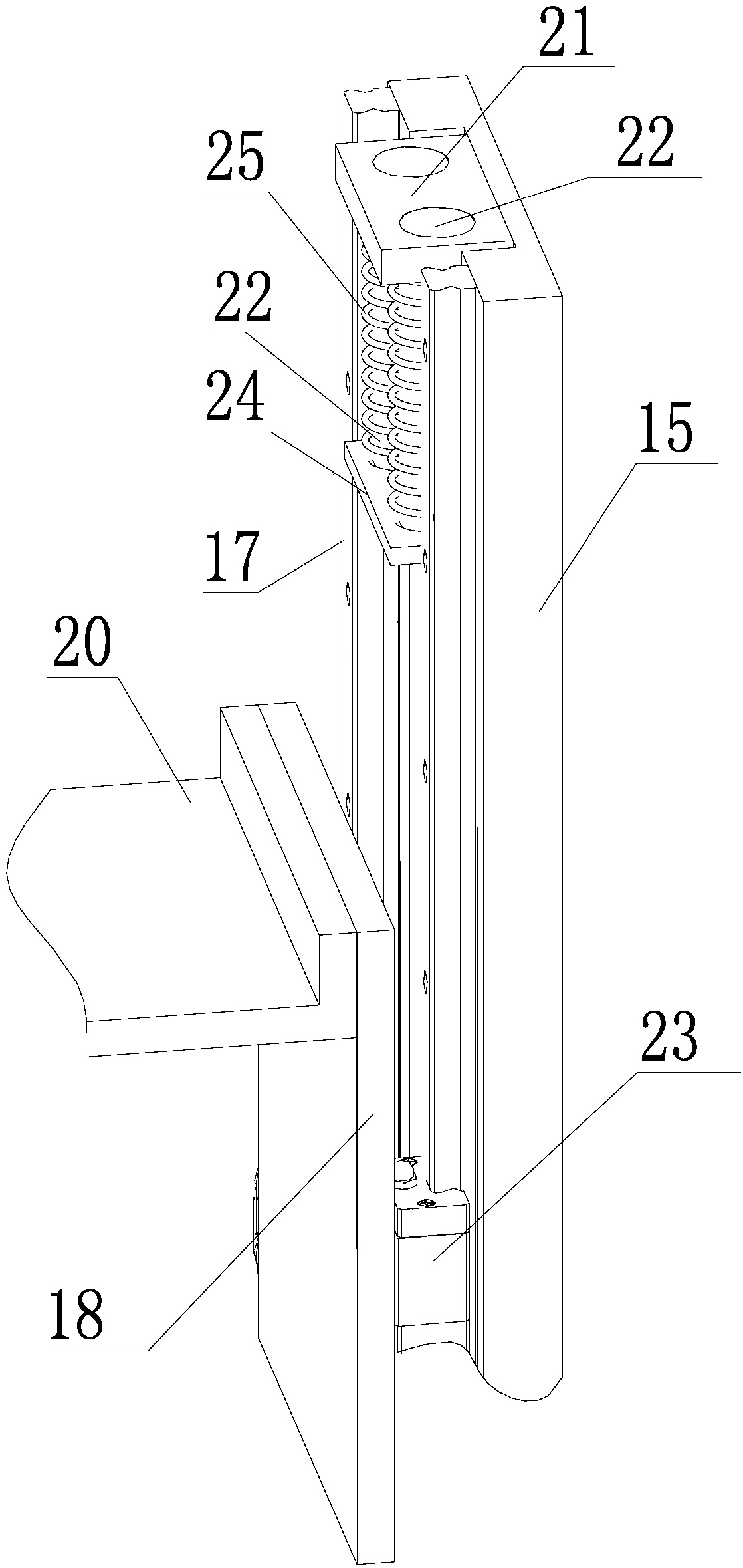

[0028] Such as figure 2 As shown, the cotter pin detection robot of the control rod guide cylinder includes a vehicle body 1, a vertical lifting mechanism, a probe assembly, a video positioning mechanism, and a three-degree-of-freedom positioning mechanism installed on the vehicle body 1. The three-degree-of-freedom positioning mechanism includes θ-axis drive mechanism, Y-axis drive mechanism mounted on the vehicle body 1, and X-axis drive mechanism mounted on the Y-axis drive mechanism, the vertical lifting mechanism is mounted on the X-axis drive mechanism, so The θ-axis driving mechanism is installed on the vertical lifting mechanism, the probe assembly is installed on the θ-axis driving mechanism, and the driving direction of the X-axis driving mechanism is perpendicular to the Y-axis driving direction and both are perpendicular to the vehicle. The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com