Peanut planting device

A peanut planting and inner tube technology, which is applied in botany equipment and methods, container cultivation, horticulture, etc., can solve the problem that the planting basket cannot be easily pulled out, and achieve the goal of saving labor, reducing resistance, and saving labor costs when collecting the inner tube Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

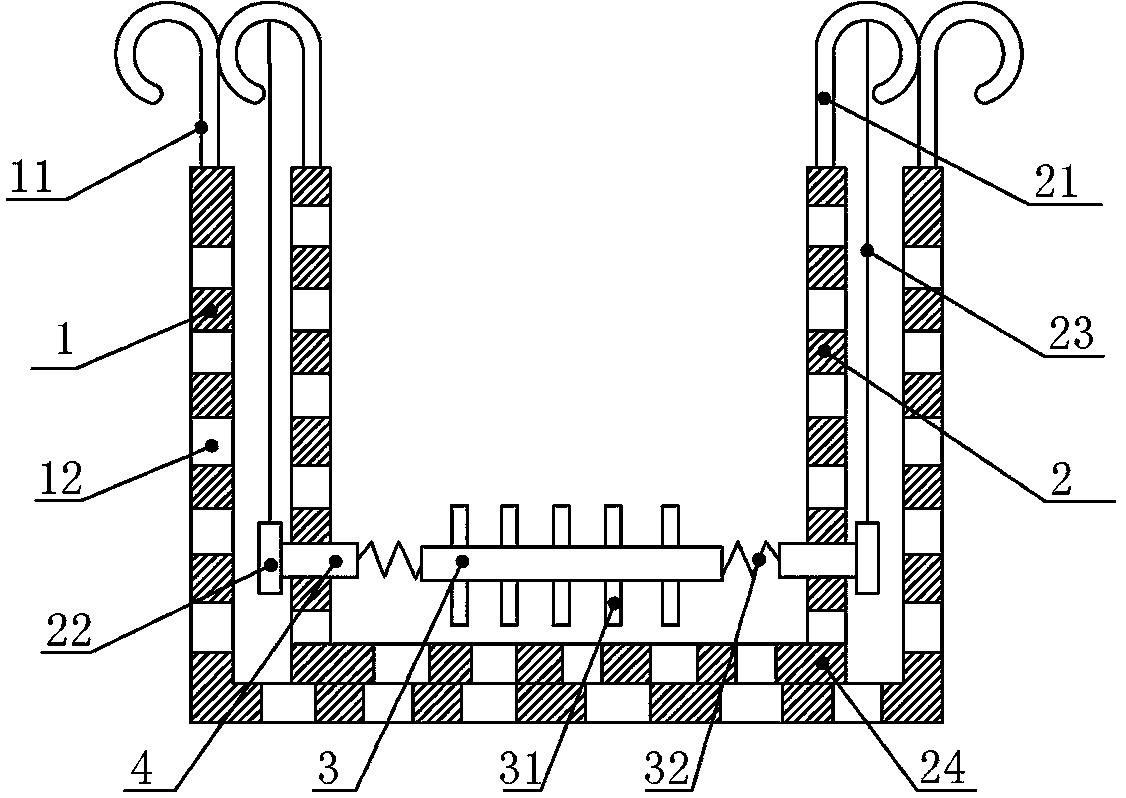

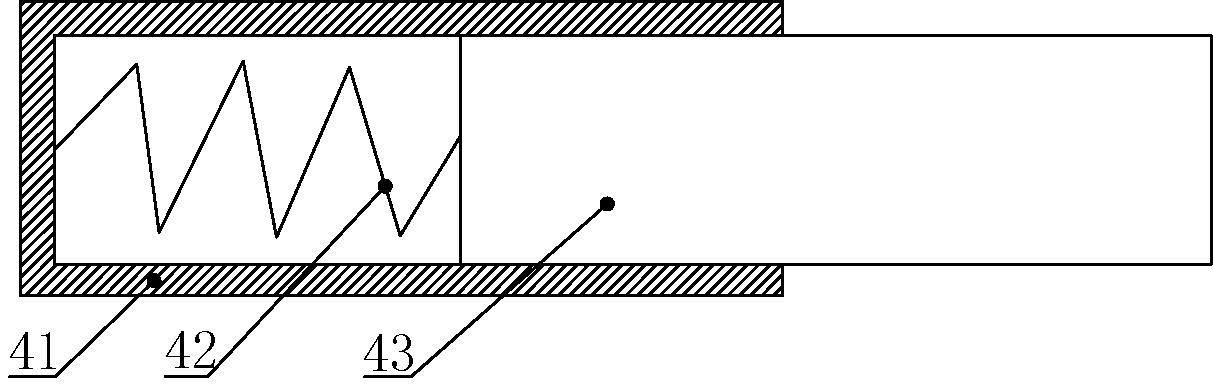

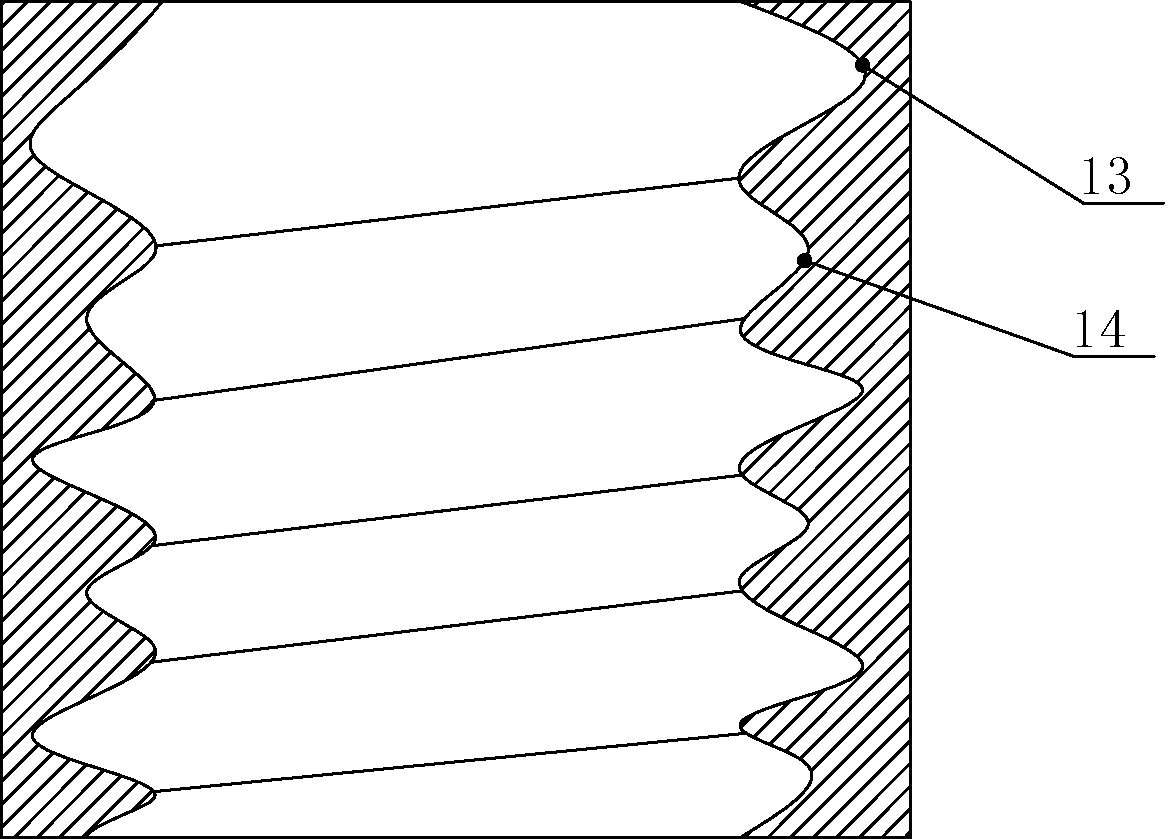

[0032] Such as figure 1 As shown, a peanut planting device includes an inner cylinder and an outer cylinder 1, the outer cylinder 1 is sleeved outside the inner cylinder, and the inner cylinder and the outer cylinder 1 are provided with several through holes 12, such as Figure 4 As shown, an annular cutter 15 is welded on the edge of the through hole 12 . The top of the inner cylinder is welded with two first handles 21, the inner cylinder includes an inner cylinder wall 2 and an inner cylinder bottom 24, the inner cylinder wall 2 is slidably connected to the inner cylinder bottom 24 and a limit card is welded on the inner cylinder bottom 24; A stirring shaft 3 is installed inside the cylinder, and ten stirring blades 31 are welded on the stirring shaft 3, and each stirring blade 31 is covered with a rubber sleeve; a first spring 32 is connected between the right end of the stirring shaft 3 and the inner cylinder wall 2 , the left end of the stirring shaft 3 is connected wit...

Embodiment 2

[0039] Such as Figure 5 As shown, the difference between this embodiment and the first embodiment is that the cutting knife 15 provided on the through hole 12 in the first embodiment is replaced by cutting teeth 16 . Embodiment 2 can also achieve the effect achieved by Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com