Sole manufacturing equipment with automatic die taking and die sinking capability

A kind of manufacturing equipment and automatic technology, which is applied in the direction of household components, household appliances, and other household appliances, can solve the problems of high labor intensity, increased production cost, and burns of workers, so as to reduce labor, labor costs, and labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

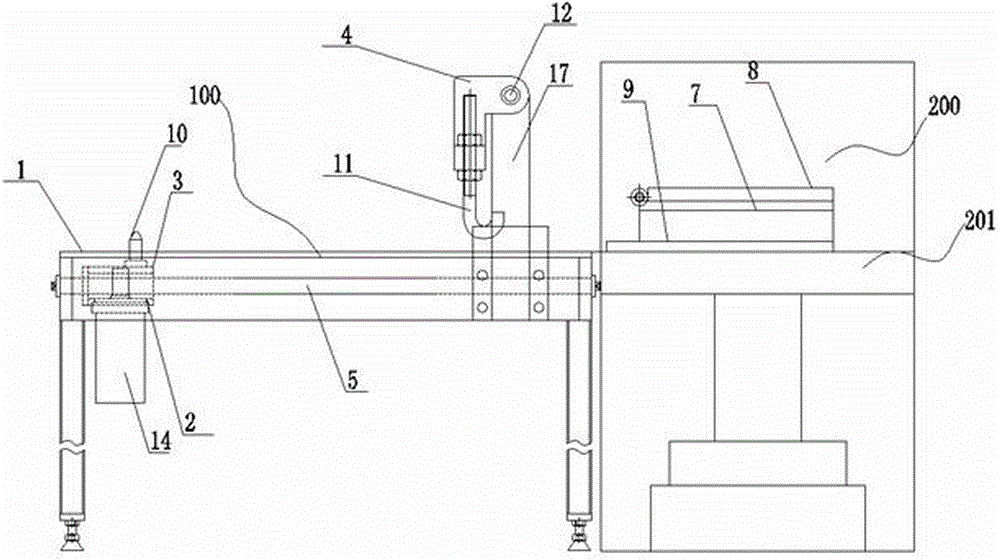

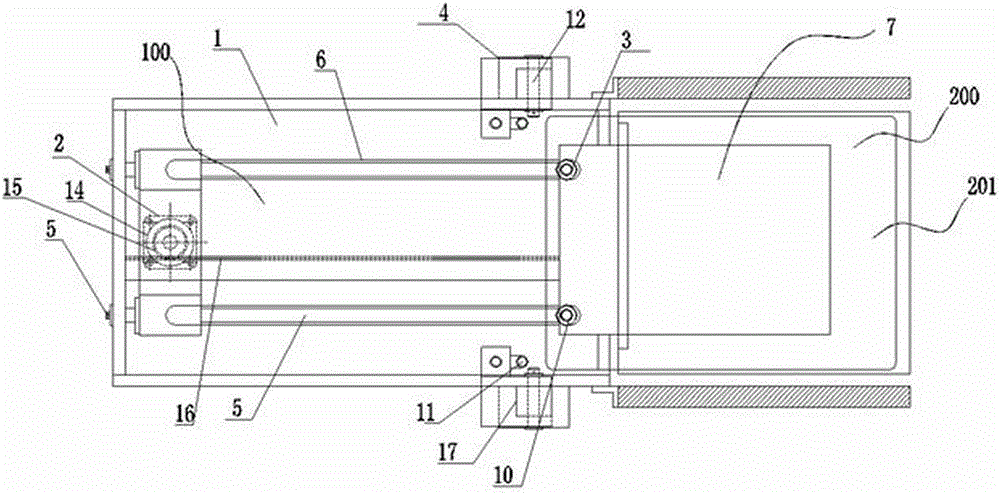

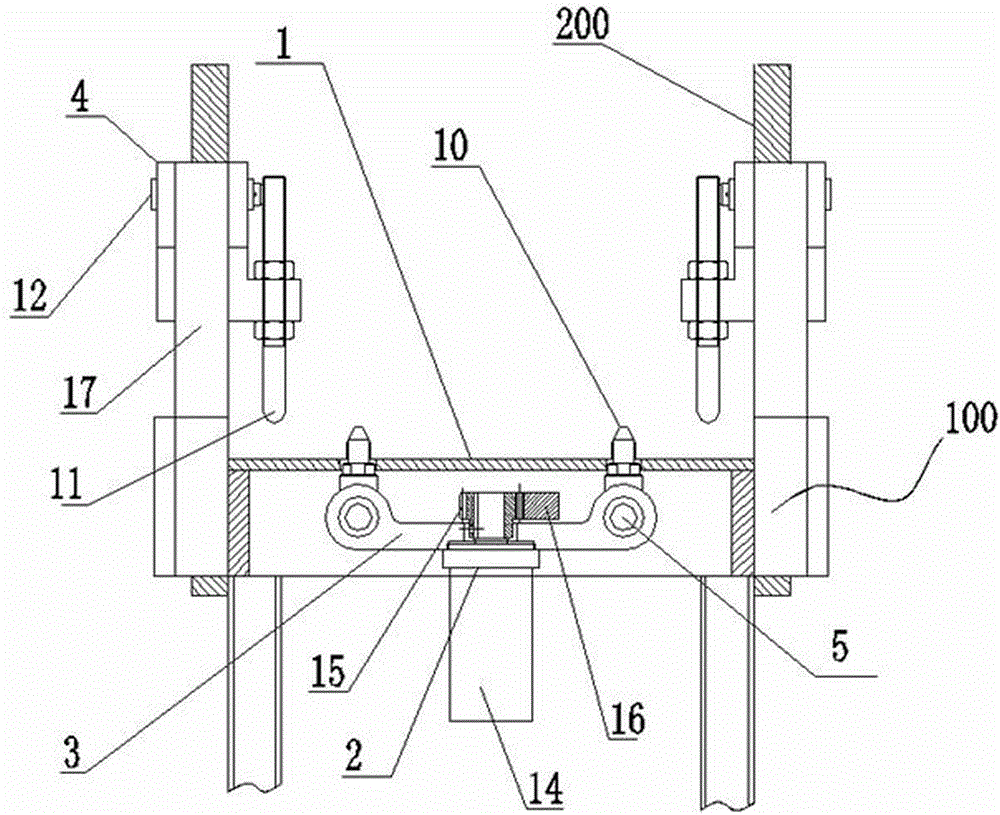

[0023] As a preferred embodiment of the present invention, with reference to the attached Figure 1-4 , this example discloses:

[0024] The shoe sole manufacturing equipment for automatic mold taking and mold opening includes a shoe sole thermocompression forming device 200 and a shoe mold conveying device 100, and the shoe mold conveying device 100 includes an operating table 1, a driving mechanism 2, a mold taking part 3 and a mold opening part 4, The operating table 1 is on the same horizontal plane as the hot-pressing material plate 201 of the shoe sole thermoforming device 200; a guide shaft 5 is arranged below the operating table 1, and the mold-taking part 3 is arranged on the guide shaft 5, and Driven by the driving mechanism 2, it reciprocates along the guide shaft 5, and is used to send the shoe mold 7 onto the thermocompression joining plate 201 of the thermocompression forming device; the operating table 1 is provided with a through groove 6, and the mold parts ar...

Embodiment 2

[0026] As another preferred embodiment of the present invention, with reference to the attached Figure 1-4 , this example discloses:

[0027] The shoe sole manufacturing equipment for automatic mold taking and mold opening includes a shoe sole thermocompression forming device 200 and a shoe mold conveying device 100, and the shoe mold conveying device 100 includes an operating table 1, a driving mechanism 2, a mold taking part 3 and a mold opening part 4, The operating table 1 is on the same horizontal plane as the hot-pressing material plate 201 of the shoe sole thermoforming device 200; a guide shaft 5 is arranged below the operating table 1, and the mold-taking part 3 is arranged on the guide shaft 5, and Driven by the driving mechanism 2, it reciprocates along the guide shaft 5, and is used to send the shoe mold 7 onto the thermocompression joining plate 201 of the thermocompression forming device; the operating table 1 is provided with a through groove 6, and the mold pa...

Embodiment 3

[0030] As another preferred embodiment of the present invention, with reference to the attached Figure 1-4 , this example discloses:

[0031]The shoe sole manufacturing equipment for automatic mold taking and mold opening includes a shoe sole thermocompression forming device 200 and a shoe mold conveying device 100, and the shoe mold conveying device 100 includes an operating table 1, a driving mechanism 2, a mold taking part 3 and a mold opening part 4, The operating table 1 is on the same horizontal plane as the hot-pressing material plate 201 of the shoe sole thermoforming device 200; a guide shaft 5 is arranged below the operating table 1, and the mold-taking part 3 is arranged on the guide shaft 5, and Driven by the driving mechanism 2, it reciprocates along the guide shaft 5, and is used to send the shoe mold 7 onto the thermocompression joining plate 201 of the thermocompression forming device; the operating table 1 is provided with a through groove 6, and the mold par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com