Power cable erecting device

A technology for power cables and equipment, applied in the field of cable erection, which can solve problems such as inconsistent soil density, uneven settlement of soil foundation, and tipping of erecting poles, so as to speed up the progress, improve the efficiency of compaction work, and reduce the quality of compaction. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

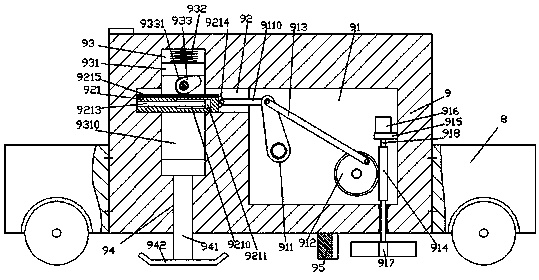

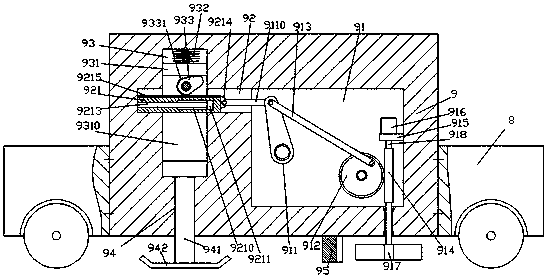

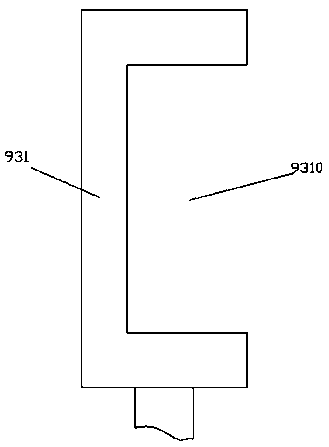

[0015] Such as Figure 1-Figure 4 As shown, a power cable erection device of the present invention includes a base body 8 and a compacting machine 9 fixed in the base body 8, and a chamber 91 is arranged in the compacting machine 9, and the left side of the chamber 91 The inner wall of the side top is connected with a guide groove 92 extending to the left, and the left extension of the guide groove 92 is provided with a guide cavity 93 extending up and down. The guide hole 94 extends downward and passes through the bottom surface of the base body 8. The lift-off slide block 931 is slid and connected in the guide cavity 93, and a recessed groove 9310 is provided in the front side of the lift-off slide block 931. The inlet groove 9310 communicates with the guide groove 92, and a guide block 921 is slid and connected in the guide groove 92, and the guide block 921 is connected with the recessed groove 9310 with clearance fit, and the top surface of the guide block 921 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com