Heating device for intermediate blank

A heating device and billet technology, which is applied to workpiece heating devices, metal processing equipment, workpiece surface treatment equipment, etc., can solve problems such as temperature drop, and achieve the effect of solving billet temperature drop and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

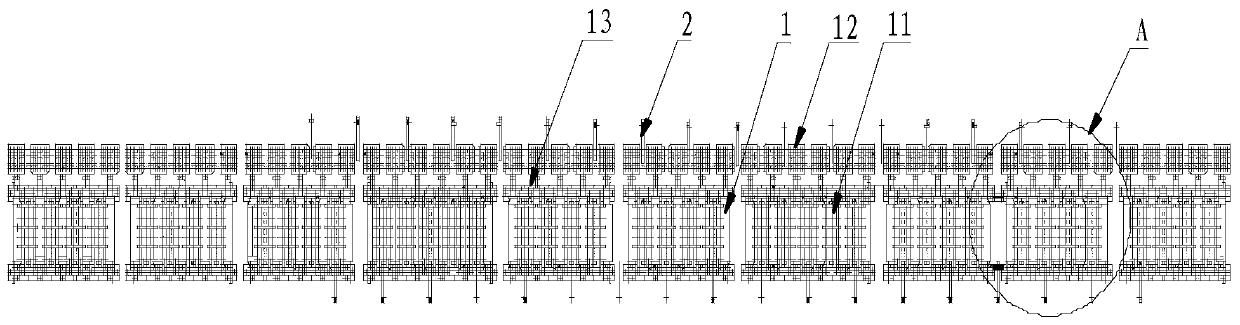

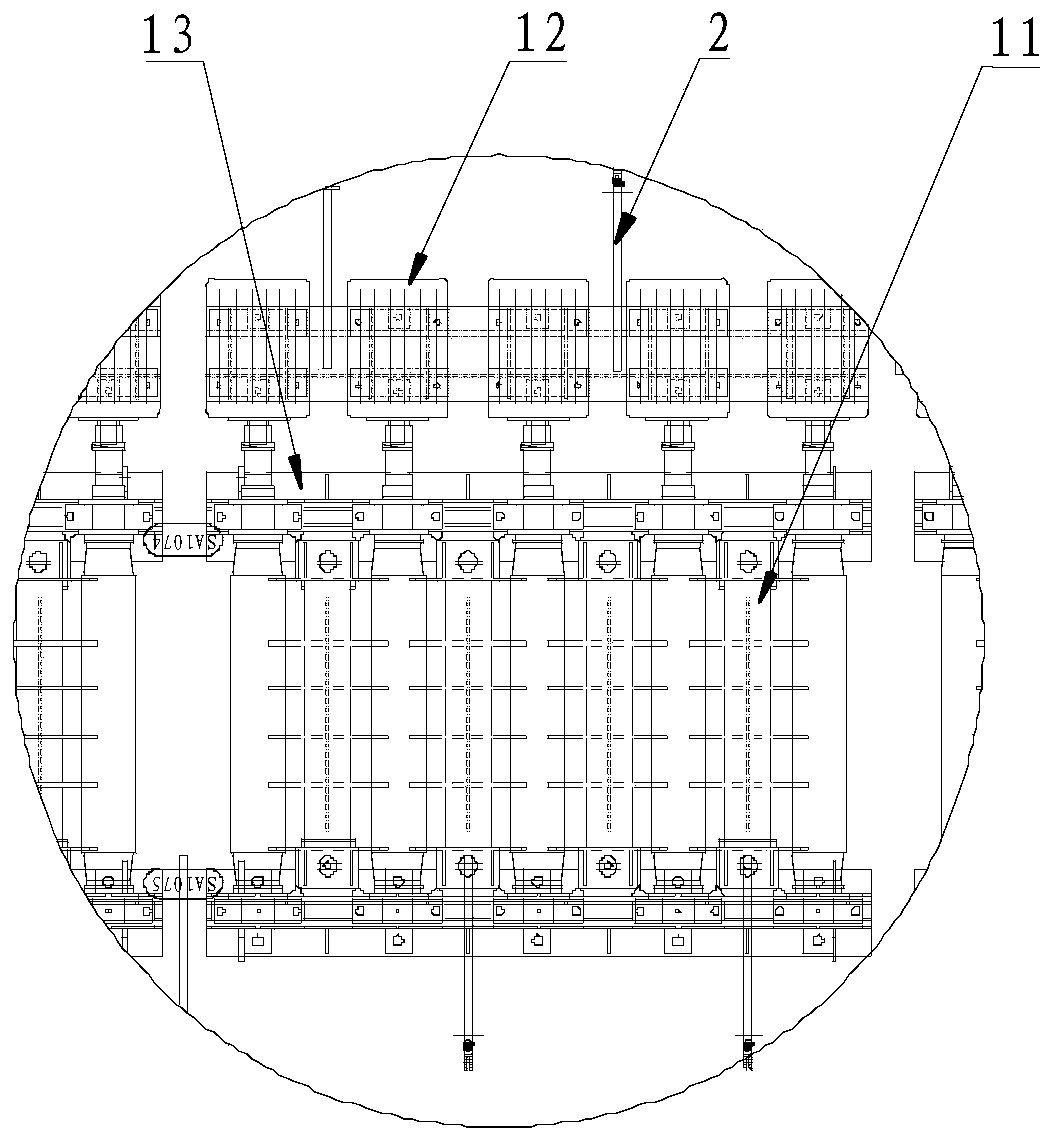

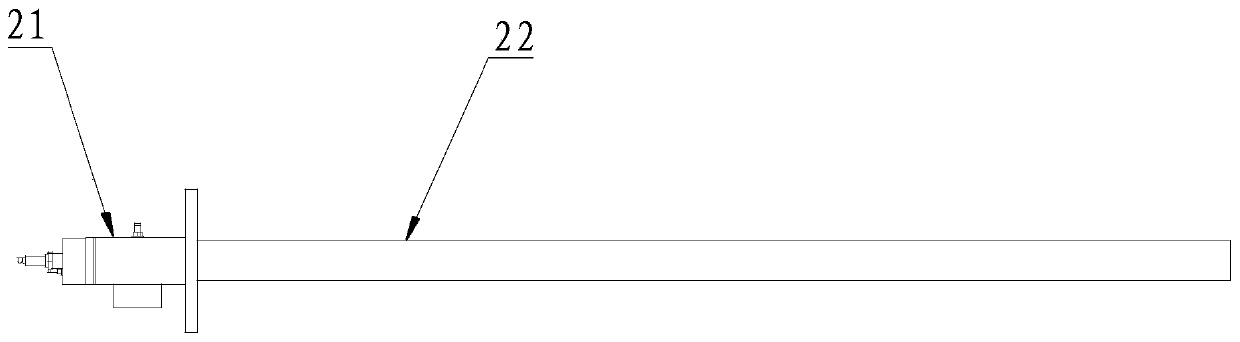

[0041] The present invention provides an intermediate billet heating device, which includes an intermediate roller table 1 and a burner assembly 2. The intermediate roller table 1 has more than two conveying rollers 11 arranged in one direction and parallel to each other. Drive motors 12 connected one-to-one at one end, guard plates 13 are respectively arranged on both sides of the middle roller table 1, and the guard plates are provided with through holes on the rear part of the middle roller table, and the through holes can accommodate the burner. The nozzle assembly 2 extends from the outside of the intermediate roller table to the inside of the intermediate roller table, and the burner assembly 2 is configured to perform heating operation on the steel billet located on the intermediate roller table.

[0042] The middle part of the conveying roller 11 has a downwardly recessed groove, and the groove width of the groove is adapted to the width of the billet. In the actual pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com