High-pressure water dephosphorization machine

A high-pressure water and phosphorus machine technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of large temperature drop of slab, splash of phosphorus removal water, hidden safety hazards, etc., to solve temperature drop and eliminate safety hazards hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

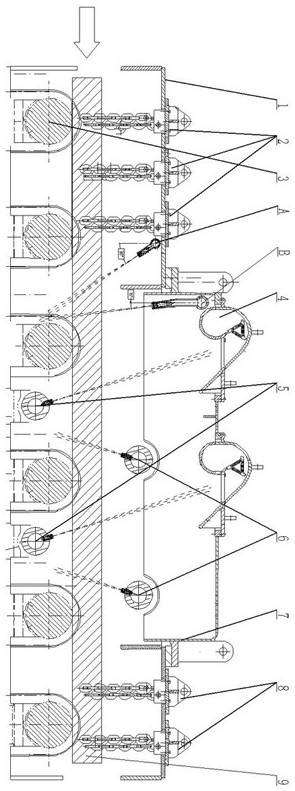

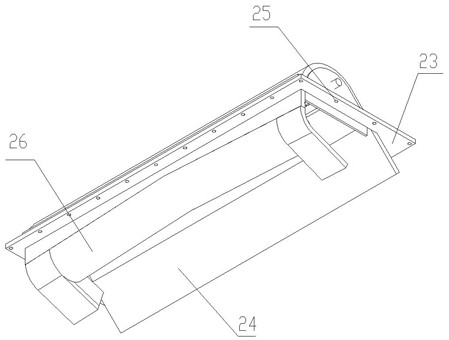

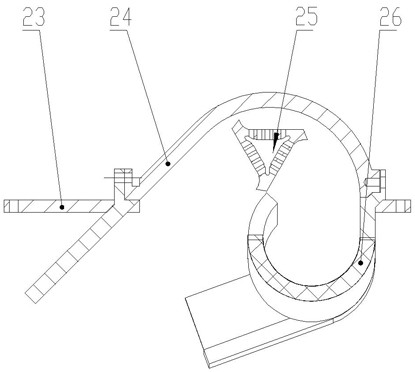

[0028] Such as Figure 1 to Figure 2 As shown, a high-pressure water dephosphorization machine includes a dephosphorization machine frame 1 and 3 conveyor rollers installed on the dephosphorization machine frame 1, a water retaining chain 8, a water collection tank 4, an upper phosphorus removal header 6, Lower phosphorus removal header 5 and shield body 7.

[0029] The phosphorus removal machine frame 1 is a frame structure, and the phosphorus removal machine frame 1 is installed at the entrance of the rolling mill.

[0030] Conveying roller table 3 has 6 rollers to form, the first one is the feed end, the sixth one is the discharge end, the rollers are driven by motors, and conveying roller table 3 is mainly used for conveying steel billet 9 .

[0031] The phosphorus removal header is divided into an upper phosphorus removal header 5 and a lower phosphorus removal header 6, which are welded by thick-walled pipes and flanges. The upper phosphorus removal header 6 is evenly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com