Desulfuration refining process of high-sulfur crude ferronickel

A coarse nickel and high sulfur technology, applied in the field of metallurgical production, can solve the problems of high energy consumption, and achieve the effects of low power consumption, low cost and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

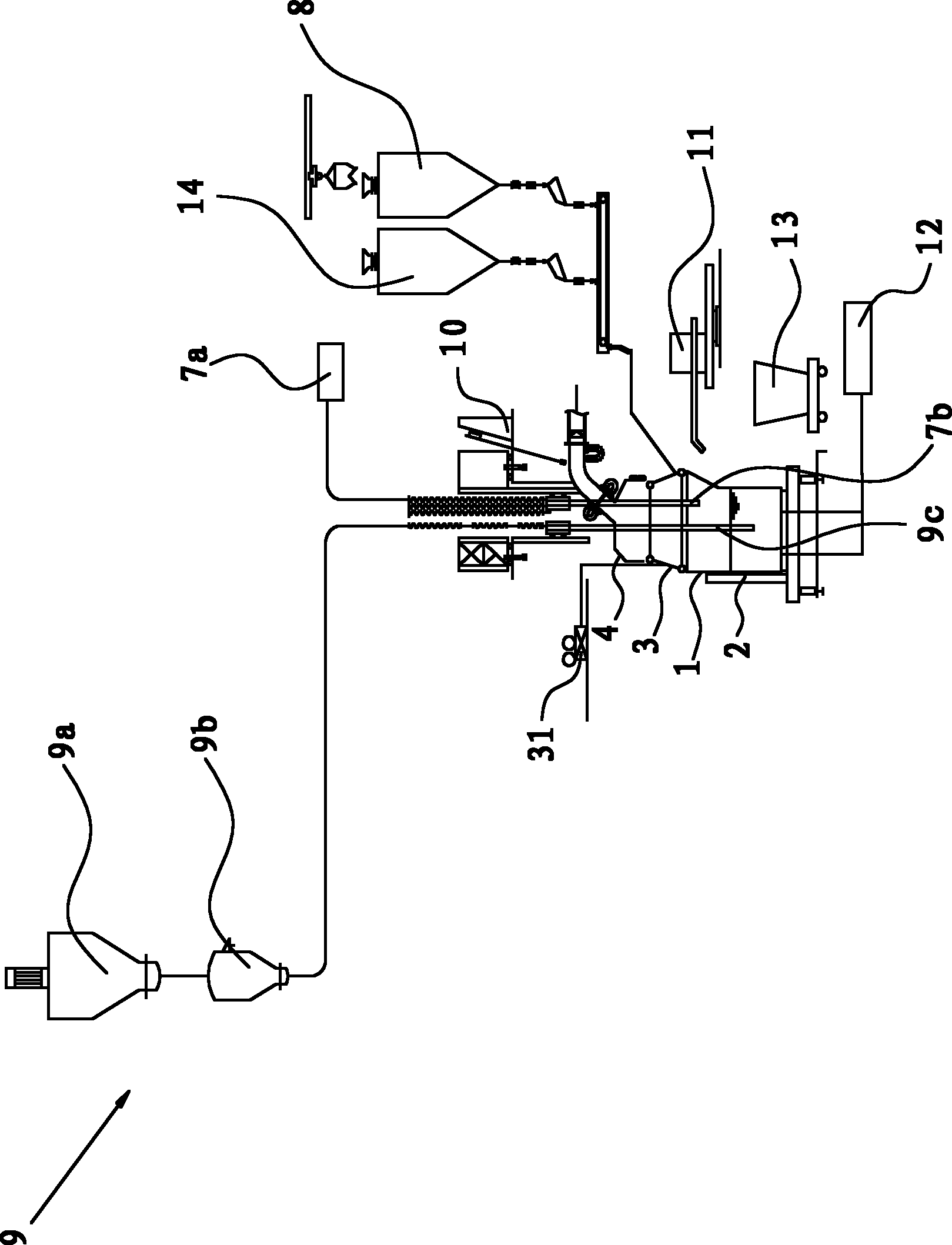

Method used

Image

Examples

Embodiment 1

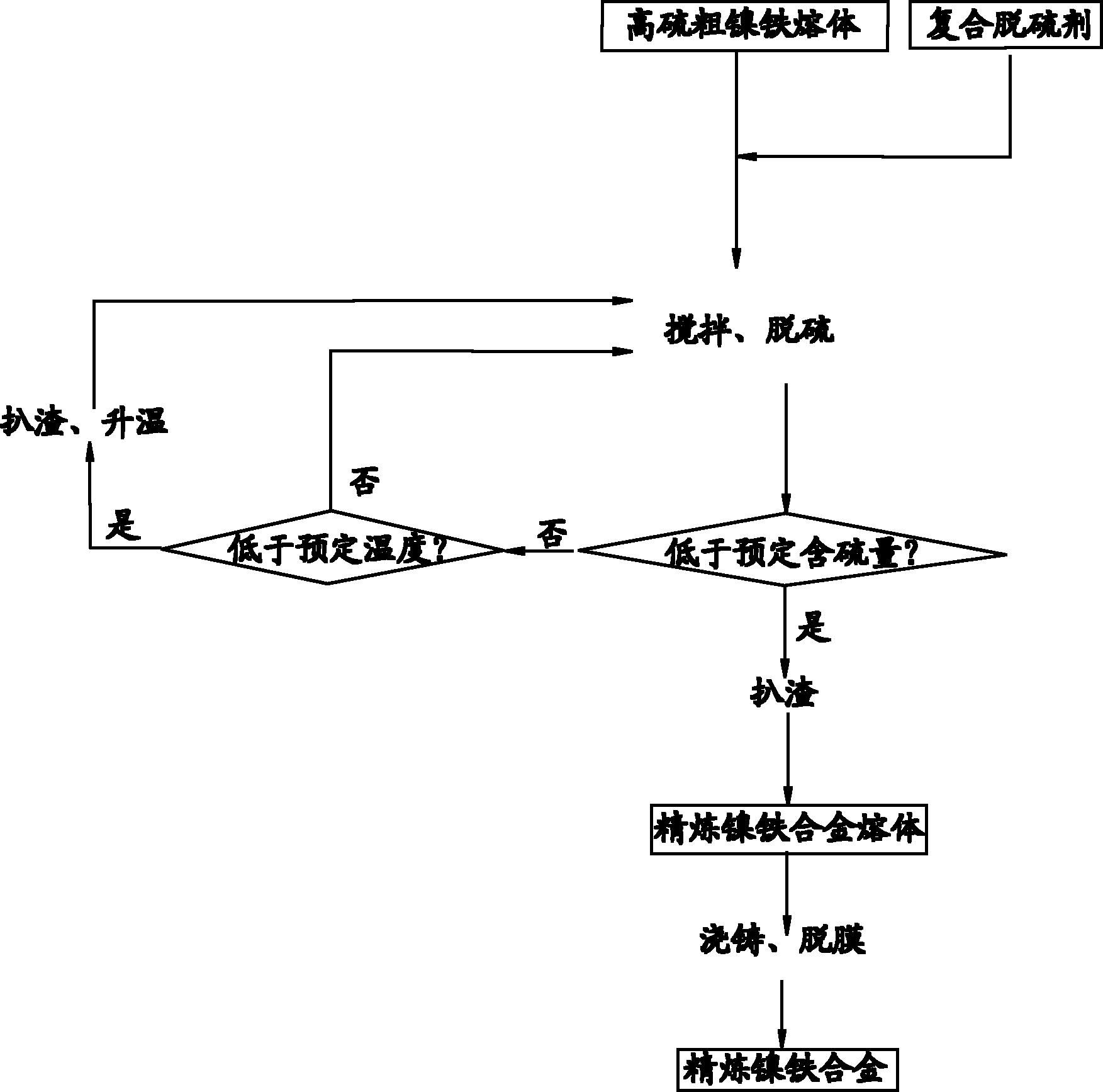

[0052] Refer below figure 2 The desulfurization and refining process of the high-sulfur crude ferronickel according to Example 1 of the present invention is described.

[0053] The crude ferronickel melt obtained from electric furnace smelting is in reducing atmosphere, suitable for desulfurization treatment. Specifically, the desulfurization process steps are as follows.

[0054] Step 1: First, provide a high-sulfur coarse ferronickel melt with an initial temperature above 1450°C. Specifically, the high-temperature high-sulfur coarse nickel-iron melt obtained by electric furnace smelting can be used, and the initial temperature obtained by electric furnace smelting is above 1450°C. In the iron tank 1, the nickel-iron tank 1 containing the thick nickel-iron melt is moved to the refining station by the nickel-iron tank moving device 2 thereafter. Thus, high-temperature high-sulfur coarse ferronickel can be directly refined, thereby saving steps such as heating and saving en...

Embodiment 2

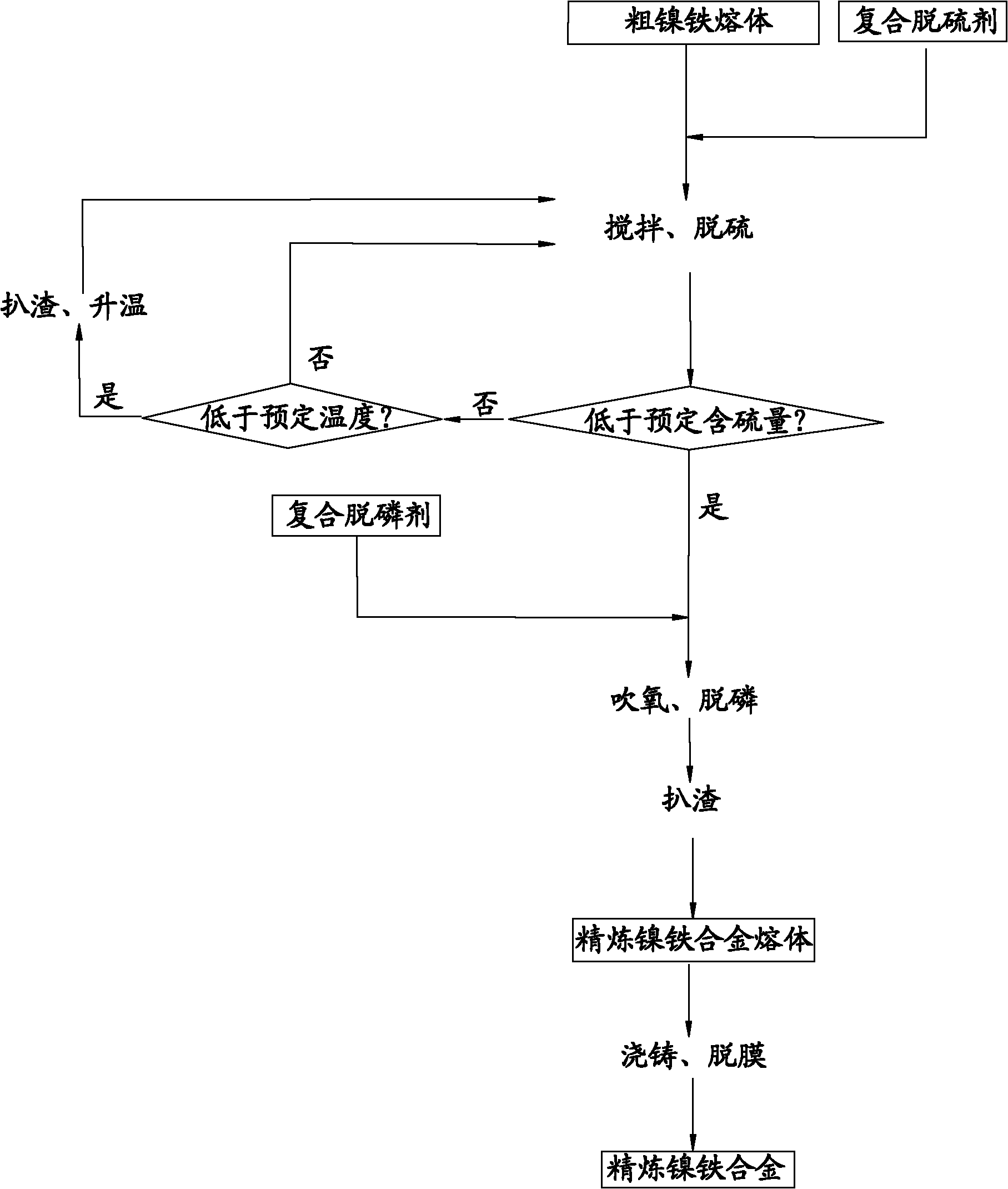

[0086] Refer below image 3 The desulfurization and refining process of high-sulfur crude ferronickel according to Example 2 of the present invention is described.

[0087] The main difference between this embodiment and the above-mentioned embodiment 1 is that, according to the specific situation of the phosphorus content contained in the crude ferronickel raw material, after desulfurization and refining, the phosphorus impurities contained therein are further dephosphorized.

[0088] Specifically, first, desulfurization was performed in the same manner as in Example 1. When the sulfur content meets the product requirements, a compound dephosphorization agent is further added to the desulfurized melt for dephosphorization.

[0089] Since part of the phosphorus contained in it has been removed through the reaction formula (8) and (9) during the desulfurization process, in the next dephosphorization process, in addition to CaO, CaCO 3 , CaF 2 In addition, ferrous oxide scale...

Embodiment 3

[0097] Refer below Figure 4 The desulfurization and refining process of the high-sulfur crude ferronickel according to Example 3 of the present invention is described. The main difference between this embodiment and embodiment 2 is that the raw material used is the coarse ferronickel obtained by sintering and rough refining of lateritic nickel ore.

[0098] Specifically, first, mix laterite nickel ore with coal powder or coke powder in a weight ratio of 90:10-95:5, and then use a rotary kiln to sinter at 600-1000°C for 2-8 hours to obtain sintered nickel ore. Thereafter, the sintered nickel ore, flux and reducing agent are put into an electric furnace and smelted at 200V-300V for 1-3 hours to obtain crude ferronickel. Then, the high-sulfur crude ferronickel produced by the electric furnace was poured into the nickel-iron tank, and refined in the same manner as in Example 2, so as to obtain refined ferronickel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com