Multifunctional hanging plate and split brick extrusion forming mold

An extrusion molding and multi-functional technology, applied in the direction of molds, etc., can solve the problems of increased construction cost, small size, and affecting the development pace of wall materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

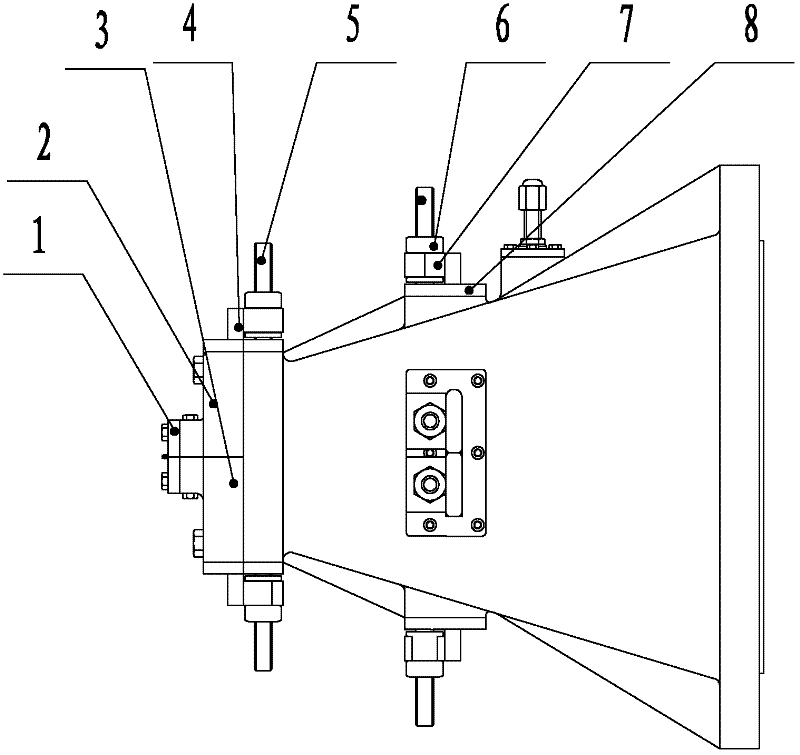

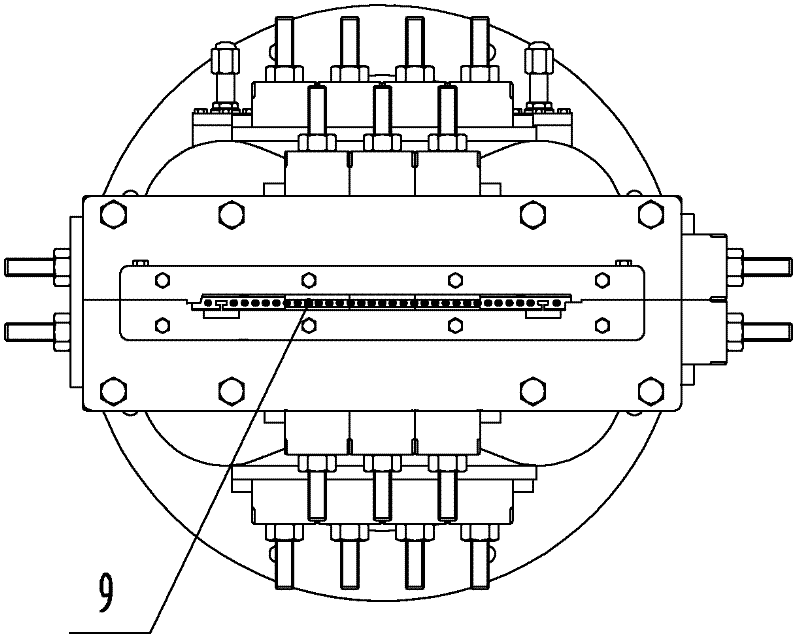

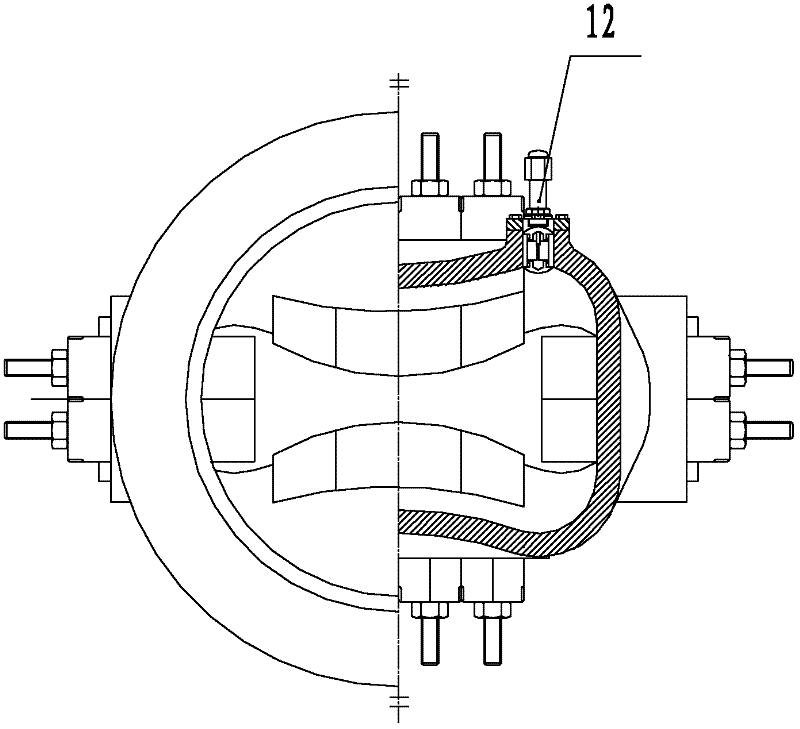

[0016] Such as Figure 1-6 A specific embodiment of the mold of the present invention is given. Multifunctional hollow hanging board and split brick extrusion molding die, characterized by the outlet forming part composed of upper and lower mouth plate 1, upper machine mouth 2 and lower machine mouth 3, which is located at the outlet end of machine head 13, adjusting plate 4 and pressing plate 1 8 forms the mud flow regulating part of the front section, and the mud flow regulating part of the middle part is composed of the regulating plate 2 10 and the pressure plate 2 11. The hole forming core tool 9 is located in the wall formed by the upper machine port 2 and the lower machine port 3 and is fixed with bolts. The cover electronic pressure sensing display device is arranged on the positions above both sides behind the segment fault in the middle of the nosepiece 13 . The shape of the head 13 is gradually changed from a circle to an inverted "8" shape section, and the width o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com