Gas distributor and gas distribution system comprising gas distributor

A technology of gas distributor and gas predistributor, which is applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of small bubble distribution area, different bubble size, uneven distribution, etc., and achieve uniform bubble size, The effect of uniform distribution and large distribution area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

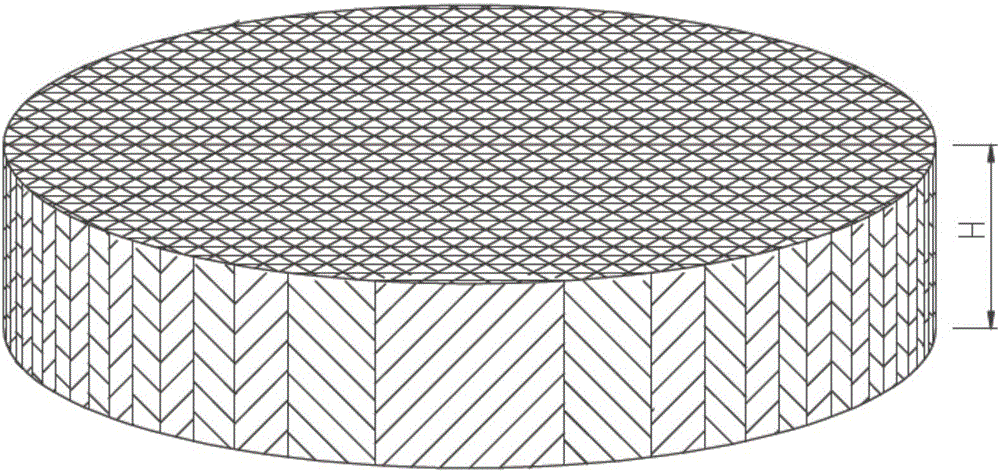

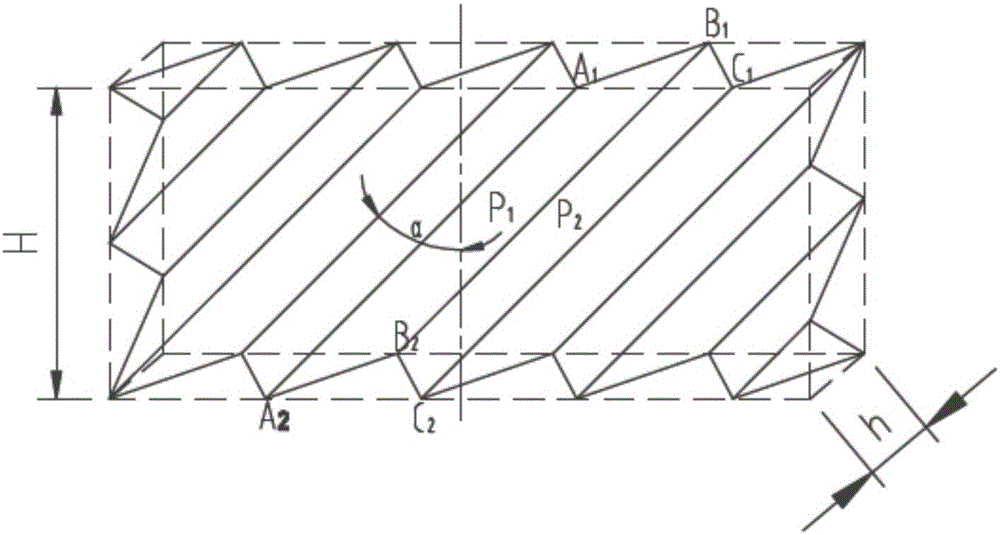

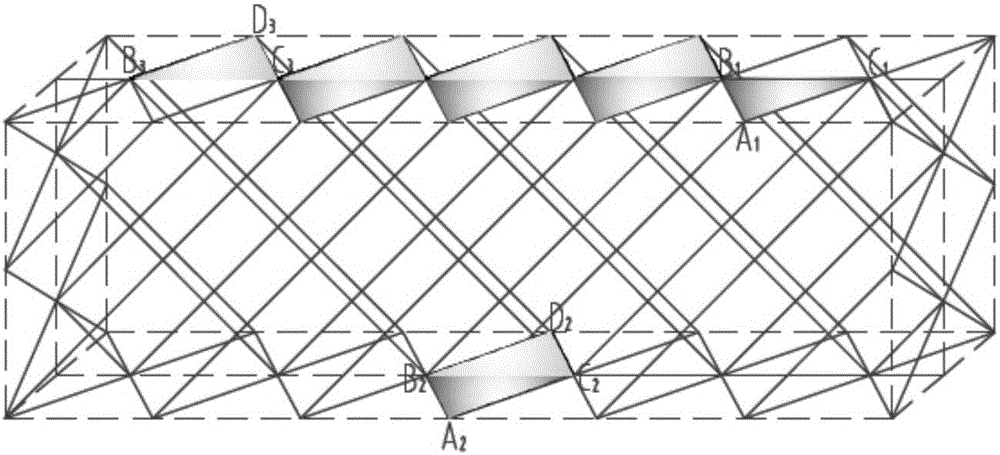

[0036] Such as figure 1 As shown, the gas distributor described in this embodiment includes a gas distribution plate, and the gas distribution plate is a plate structure assembled from several corrugated sheets; please also refer to figure 2 with image 3 , the ribs of the corrugated sheet (such as figure 2 Straight line B in 1 B2 , that is, the two wave surfaces A 1 A 2 B 2 B 1 with B 1 B 2 C 2 C 1 The intersection line) is not arranged in the vertical direction, and the inclination directions of the corrugated ribs of two adjacent corrugated sheets are opposite. The material of the corrugated sheet can be selected according to the properties of the medium in the equipment. Generally, it can be various metals or alloys. When the medium is highly corrosive and the temperature is low, suitable plastics can be selected, and the medium is highly corrosive and the temperature is low. Ceramics can be selected when it is higher; when the material of the corrugated sheet...

Embodiment 2

[0042] Figure 5 Shown is the structural representation of the slurry bed reactor that the gas distribution system of embodiment 1 is installed, and the diameter of described slurry bed reactor 1 is 2000mm, and catalyst is added in the reactor from catalyst inlet 2, and liquid is located in reactor by The liquid inlet 3 at the bottom enters the reactor, and the gas enters the reactor through the gas inlet 4 at the lower part of the reactor. After being distributed by the gas distribution system, small bubbles of uniform size and uniform distribution bubble through the liquid layer, and the catalyst is in the upward direction. Under the joint action of the flowing liquid flow and the air bubbles, they are evenly dispersed in the liquid phase, or suspended in the liquid phase; the rising air bubbles enter the gas collecting hood 5 set on the upper part of the reactor, pass through the liquid surface and pass through the top of the reactor The gas outlet 6 escapes, and the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com