Ethyl acetate phase splitter liquid level meter and ethyl acetate phase splitter

A technology of ethyl acetate and phase separator, which is applied in buoy liquid level indicator, separation/purification of carboxylate, organic chemistry, etc. The rod is easy to float and other problems, to achieve the effect of accurate interface indication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

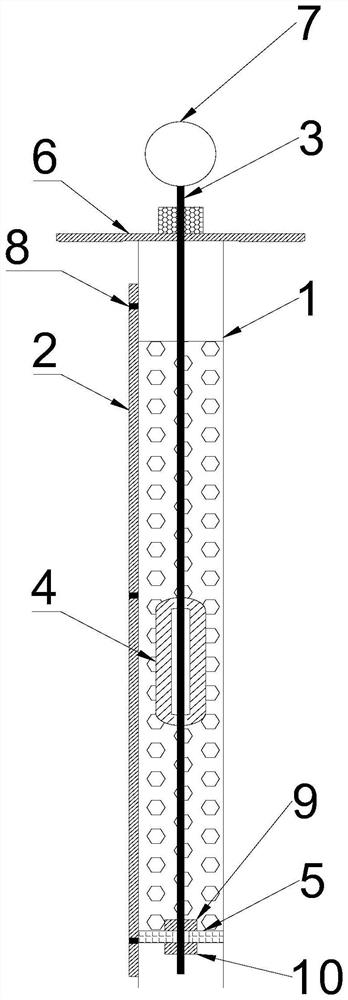

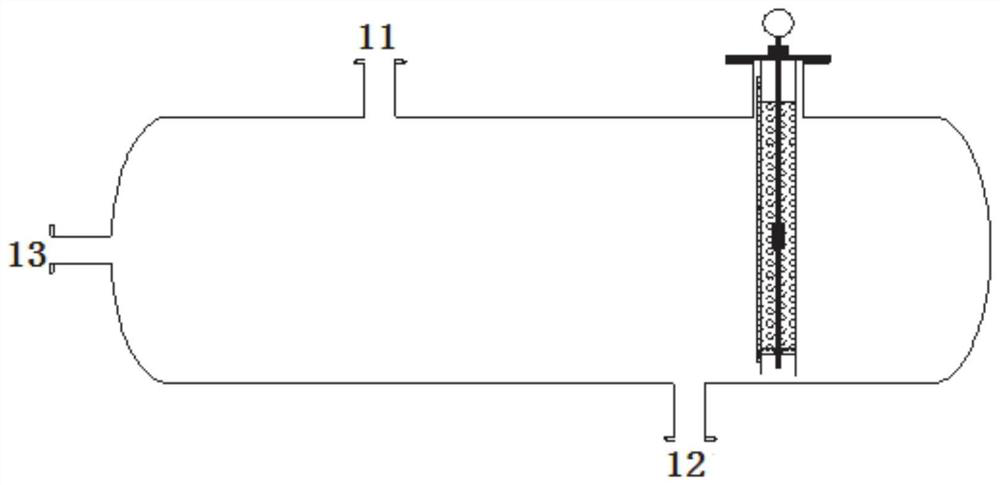

[0045] refer to figure 1 , this embodiment provides an ethyl acetate phase separator liquid level gauge, including a buoy 1, the center of the buoy 1 has a guide rod 3 that runs through the buoy 1, the guide rod 3 has a built-in magnetic sensor, and the guide rod 3 is nested with a maglev Sub 4; the bottom of the buoy 1 is open, the bottom is fixed with a positioning card 5, the positioning card 5 fixes the guide rod 3, and the positioning card 5 prevents solid particles from entering the inside of the buoy 1.

[0046] The upper part of the buoy 1 is connected to the upper flange cover 6 by welding, and the center of the buoy 1 is concentric with the hole center of the upper flange cover 6; the baffle plate 2 is welded and connected to the buoy 1 through the fan-shaped bracket 8; the lower end of the guide rod 3 passes through in turn The upper flange cover 6, the magnetic float 4, the upper positioning nut 9, the positioning card 5, and the lower positioning nut 10 complete t...

Embodiment 2

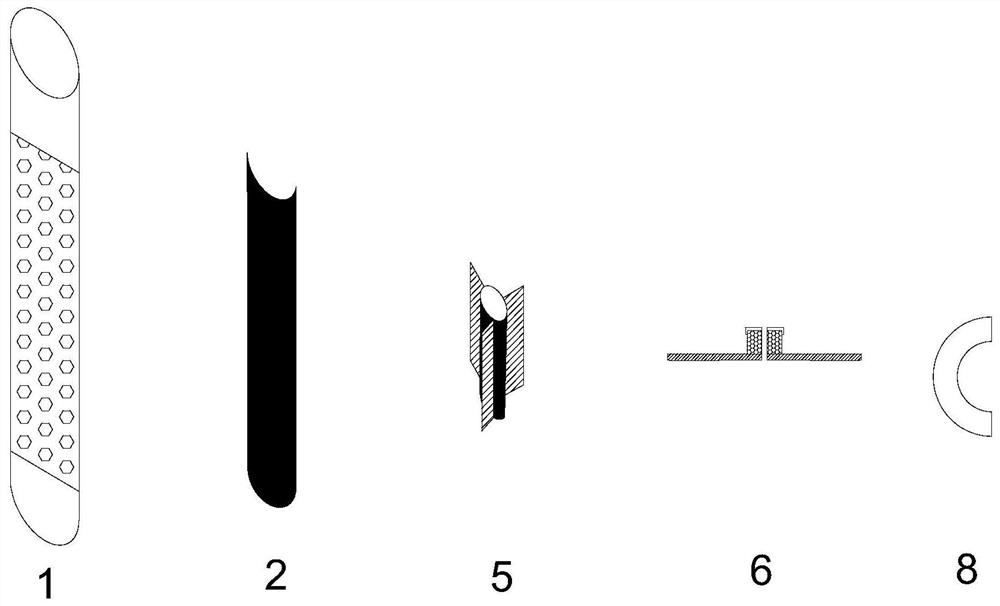

[0048] This embodiment provides an ethyl acetate phase separator liquid level gauge, which is the same as Embodiment 1, except that the buoy 1 adopts a porous structure and the lower end of the buoy 1 is open. Wherein the upper part and the lower part of the buoy 1 each have a section without a porous structure. For details, see figure 2 .

Embodiment 3

[0050] This embodiment provides an ethyl acetate phase separator liquid level gauge, the same as embodiment 1, the difference is that the baffle plate 2 adopts an arc-shaped fluid type baffle plate (see details figure 2 ). The baffle plate is installed on one side of the buoy 1 and is longer than the hollow structure of the buoy 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com