Hydrogenation test method

A hydrogenation test, hydrogen technology, applied in the direction of chemical instruments and methods, hydrocarbons, bulk chemical production, etc., can solve the threat to the safe operation of the compressor, the cooling medium cannot use water, and the compression ratio of the compressor is large. Achieve the effects of reducing equipment and operating costs, improving operating stability, and reducing equipment manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

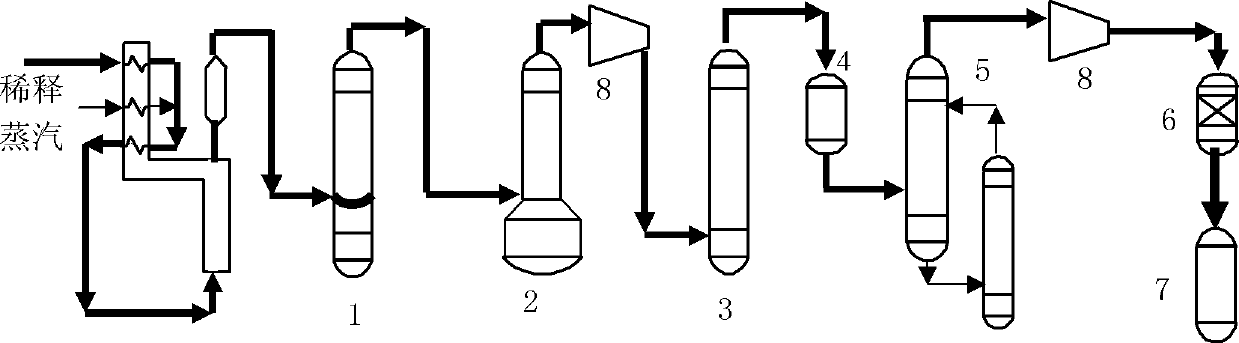

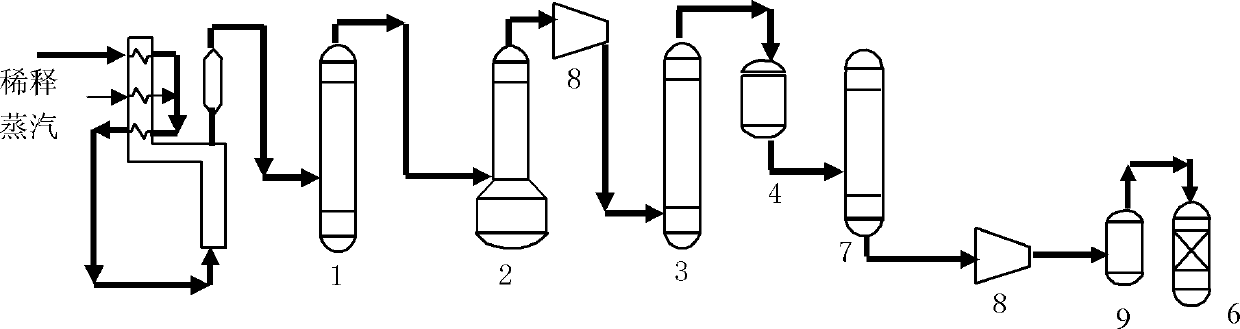

Method used

Image

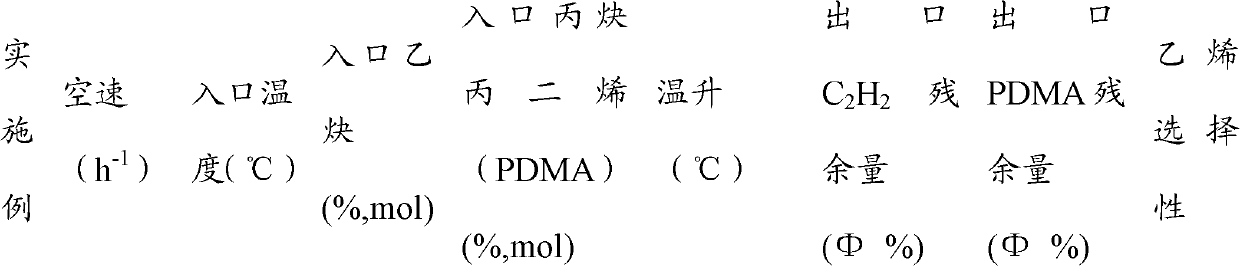

Examples

Embodiment 1

[0042] Perform primary compression on methane, increase the pressure of methane from 0.5MPa to 1.5MPa, and then mix it with carbon 2 fraction, carbon 3 fraction, and hydrogen. device.

[0043] The composition of the prepared reaction mass is:

[0044] Hydrogenation Feedstock H 2 C 2 h 2 C 2 h 4C 2 h 6 CH 4 C 3 h 6 C 3 h 8 PDMA CO C 4 +

[0045] Content (Φ%) 20 0.7 35 4.0 25 12.3 2 0.50 0.2 0.3

[0046] The loading volume of the catalyst is 300ml, and the grade of the catalyst is G-83C.

Embodiment 2

[0048] Reduce the pressure of C3 to 0.5MPa, mix it with methane, and then carry out one-stage compression, increase the pressure to 1.5MPa, and then mix it with C2 fraction and hydrogen, after mixing, two-stage compression to 4MPa, and then pass through the mass flow meter distributed to each reactor.

[0049] The composition of the prepared reaction mass is:

[0050] Hydrogenation Feedstock H 2 C 2 h 2 C 2 h 4 C 2 h 6 CH 4 C 3 h 6 C 3 h 8 PDMA CO C 4 +

[0051] Content (Φ%) 19 0.7 35 4.3 25 13 2 0.50 0.2 0.3

Embodiment 3

[0053] Compress methane in one stage until the pressure increases to 1.6MPa, reduce the pressure of C3 to 2.0MPa, then mix it with carbon distillate and hydrogen, and compress it in two stages to 4MPa after mixing, and then distribute it to each reactor through a mass flow meter .

[0054] The composition of the prepared reaction mass is:

[0055] Hydrogenation Feedstock H 2 C 2 h 2 C 2 h 4 C 2 h 6 CH 4 C 3 h 6 C 3 h 8 PDMA CO C 4 +

[0056] Content (Φ%) 22 0.7 33.3 4.0 24 13 2 0.50 0.2 0.3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com