A kind of preparation method of high lanthanum low niobium optical glass containing titanium

An optical glass and glass technology, which is applied in the field of preparation of high lanthanum and low niobium optical glass, can solve the problems of unsolvable glass crystallization problems, large glass crystallization tendency, increased glass erosion, etc., so as to shorten the glass clarification and homogenization time. , The effect of less glass crystallization tendency and less glass defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

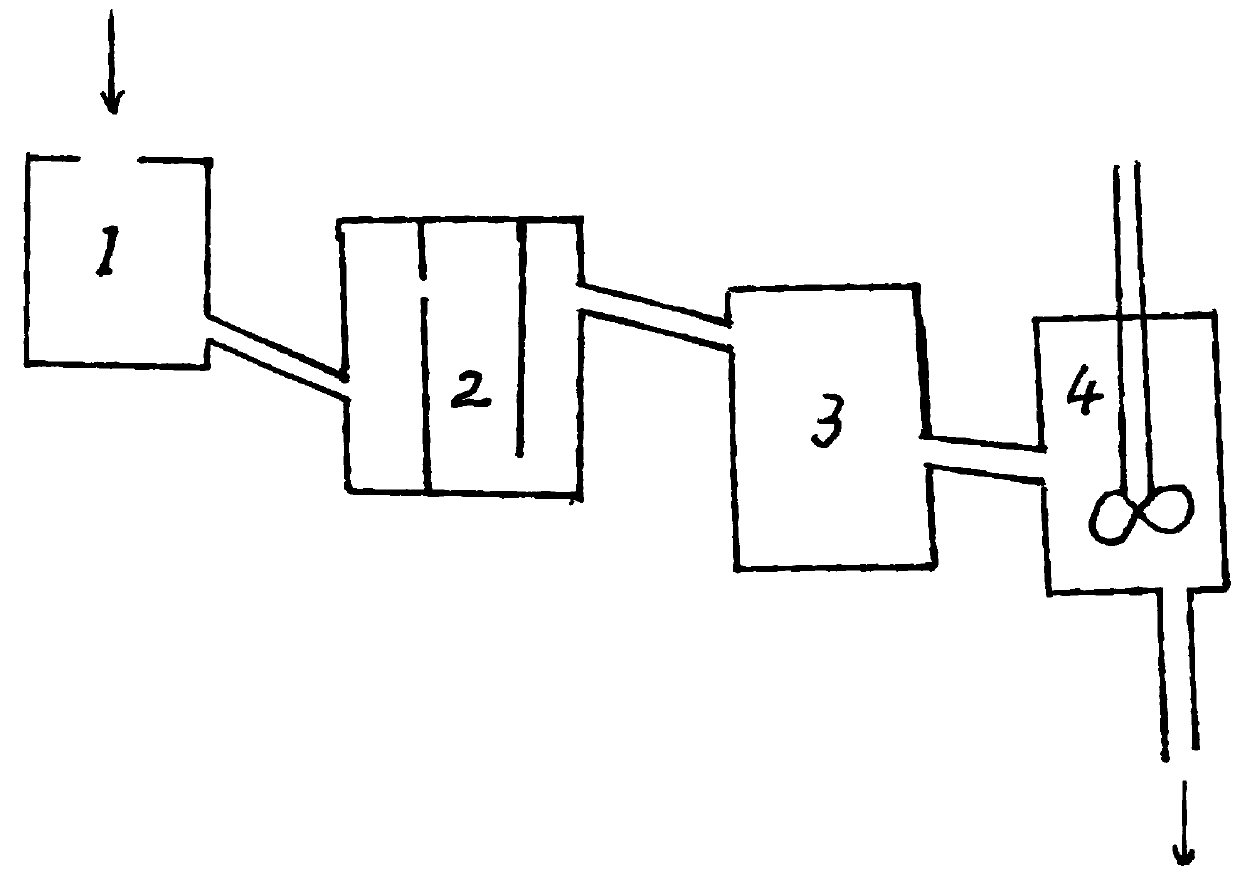

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of titanium-containing high-lanthanum and low-niobium optical glass,

[0042] The first step, batch preparation

[0043] 1) Weigh 16wt% quartz sand, 1wt% germanium oxide, 11wt% niobium pentoxide, 8wt% titanium dioxide, 16wt% calcium carbonate, 26wt% lanthanum trioxide, 10wt% % anhydrous boric anhydride, 2 wt% barium nitrate, 4 wt% barium carbonate, 3 wt% anhydrous sodium nitrate, 1.07 wt% zirconium dioxide, 1.90 wt% gallium oxide, 0.03 wt% trioxide Antimony;

[0044] 2) Sodium nitrate and barium nitrate are crushed through a wheel mill and a vibrating sieve so that they can completely pass through a 30-mesh standard sieve;

[0045] 3) Put the weighed anhydrous boric anhydride, barium nitrate, sodium nitrate, calcium carbonate, and antimony trioxide into the V-shaped mixer and mix for 12 minutes to form a small mixed material;

[0046] 4) Put the well-mixed small material and the remaining several other raw materials into the QH-type powerful mixe...

Embodiment 2

[0066] A preparation method of titanium-containing high-lanthanum and low-niobium optical glass,

[0067] The first step, batch preparation

[0068] 1) Weigh 17wt% quartz sand, 1.5wt% germanium oxide, 10wt% niobium pentoxide, 9.5wt% titanium dioxide, 14wt% calcium carbonate, 24wt% lanthanum trioxide, 9.5 wt% anhydrous boric anhydride, 2.5 wt% barium nitrate, 4.5 wt% barium carbonate, 1 wt% anhydrous sodium nitrate, 3.96 wt% zirconium dioxide, 2.50 wt% gallium oxide, 0.04 wt% Antimony trioxide;

[0069] 2) Sodium nitrate and barium nitrate are crushed through a wheel mill and a vibrating sieve so that they can completely pass through a 30-mesh standard sieve;

[0070] 3) Put the weighed anhydrous boric anhydride, barium nitrate, sodium nitrate, calcium carbonate, and antimony trioxide into a V-shaped mixer and mix for 15 minutes to form a small mixed material;

[0071] 4) Put the uniformly mixed small material and the remaining several other raw materials into the QH type po...

Embodiment 3

[0090] A preparation method of titanium-containing high-lanthanum and low-niobium optical glass,

[0091] The first step, batch preparation

[0092] 1) Weigh 19wt% of quartz sand, 2wt% of germanium oxide, 9wt% of niobium pentoxide, 9.5wt% of titanium dioxide, 13wt% of calcium carbonate, 22.45wt% of Lanthanum, 10 wt% anhydrous boric anhydride, 1.2 wt% barium nitrate, 6 wt% barium carbonate, 2.5 wt% anhydrous sodium nitrate, 2.8 wt% zirconium dioxide, 2.5 wt% gallium oxide, 0.05 wt% antimony trioxide;

[0093] 2) Sodium nitrate and barium nitrate are crushed through a wheel mill and a vibrating sieve so that they can completely pass through a 30-mesh standard sieve;

[0094] 3) Put the weighed anhydrous boric anhydride, barium nitrate, sodium nitrate, calcium carbonate, and antimony trioxide into the V-shaped mixer and mix for 18 minutes to form a small mixed material;

[0095] 4) Put the uniformly mixed small material and the remaining several other raw materials into the QH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com