Rolled reverse osmosis membrane element with gradually-reduced inlet channel

A technology of reverse osmosis membrane and inlet flow channel, which is applied in the field of reverse osmosis membrane elements and roll reverse osmosis membrane elements, can solve the problems of difficulty in achieving gradient thickness and lack of operability of the inlet water diversion net.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

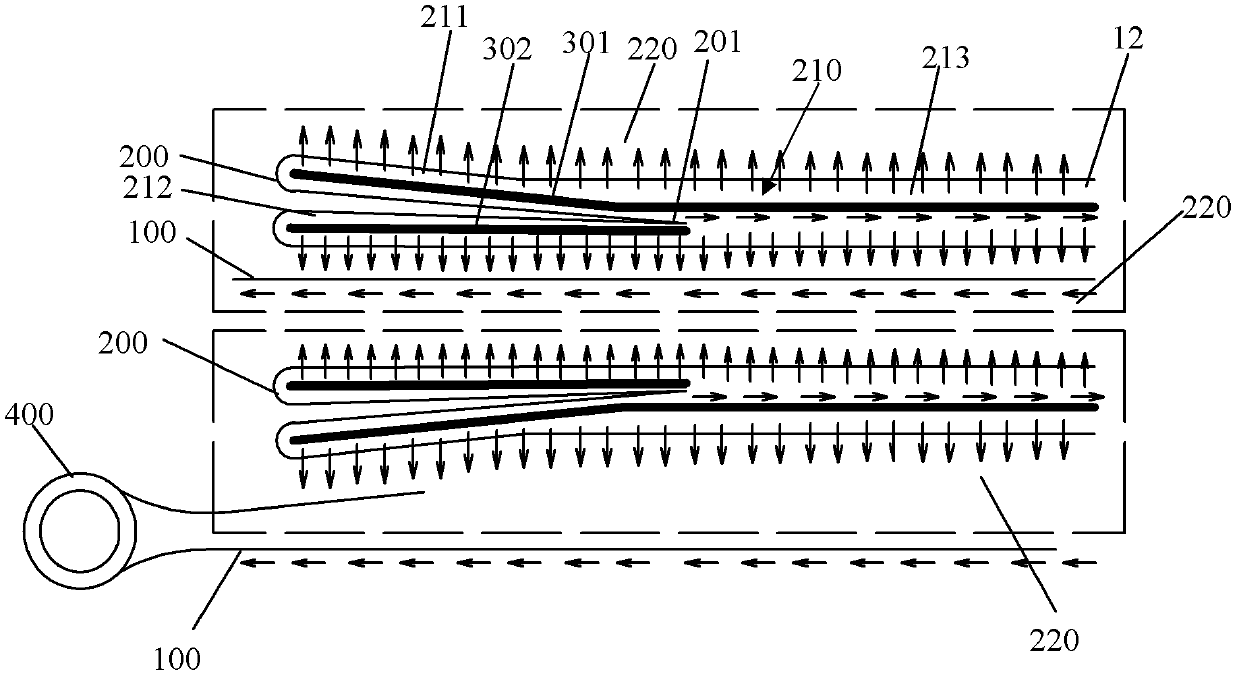

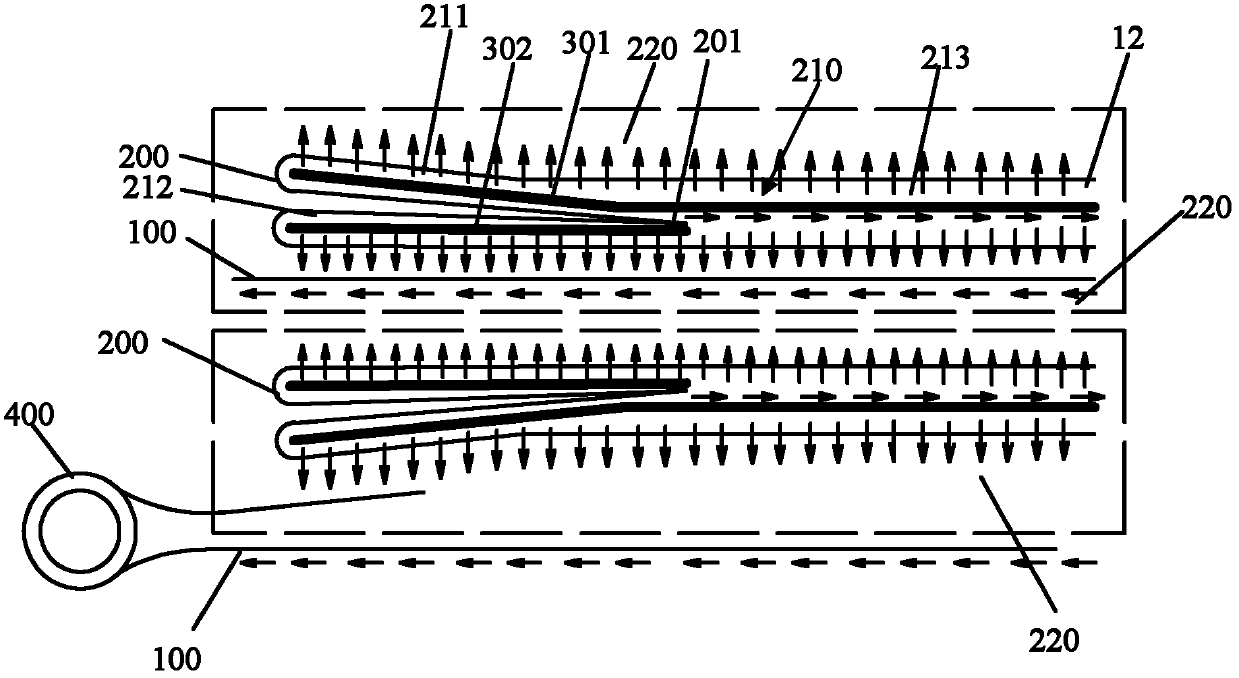

[0012] Such as figure 1 As shown, the roll-type reverse osmosis membrane element 10 with variable flow channel network thickness of the present invention consists of two sets of water purification membrane groups 11 composed of a pure water diversion net 100, a reverse osmosis membrane 200, and an inlet diversion net. It is formed by winding on the central water production pipe 400.

[0013] Among them, the reverse osmosis membrane 200 is folded into a transverse "M" shape, that is, there are three sides on the side of the central water pipe 400, and the middle fold is retracted into the membrane, so that the water inlet channel 210 formed on the inner surface is divided into The two forward water channels 211 and 212 in the upper and lower layers on the side of the central water production pipe 400, and the rear water channel 213 on the side of the concentrated water outlet 12 form a water production channel 220 between adjacent outer surfaces (the bottom water purification memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com