Waste heat utilization heat exchanger, with different tube bundle intervals and bulge densities, of rotary cement kiln

A cement rotary kiln and heat exchanger technology, applied in indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the problems of fouling and other problems, and achieve the advantages of reducing fouling, easy cleaning, and reducing fouling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

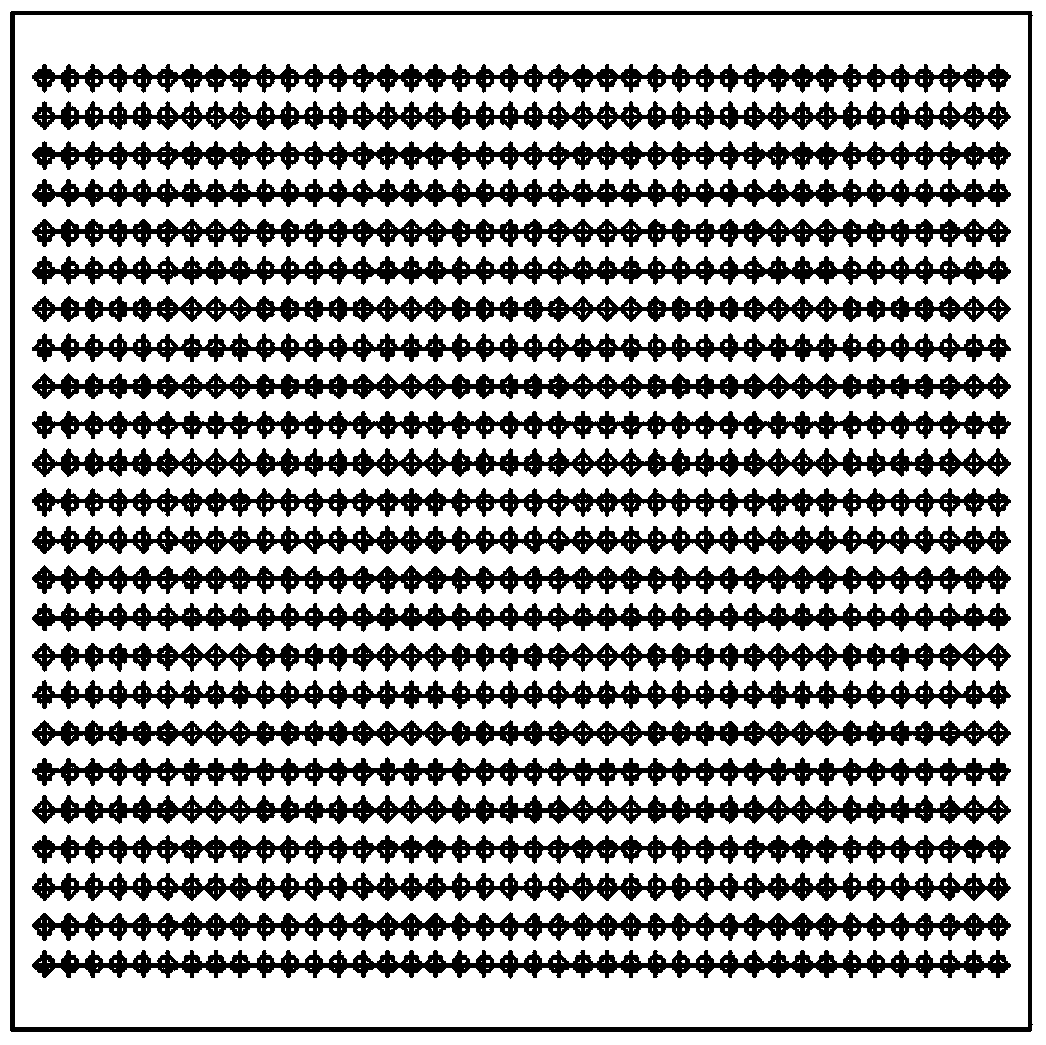

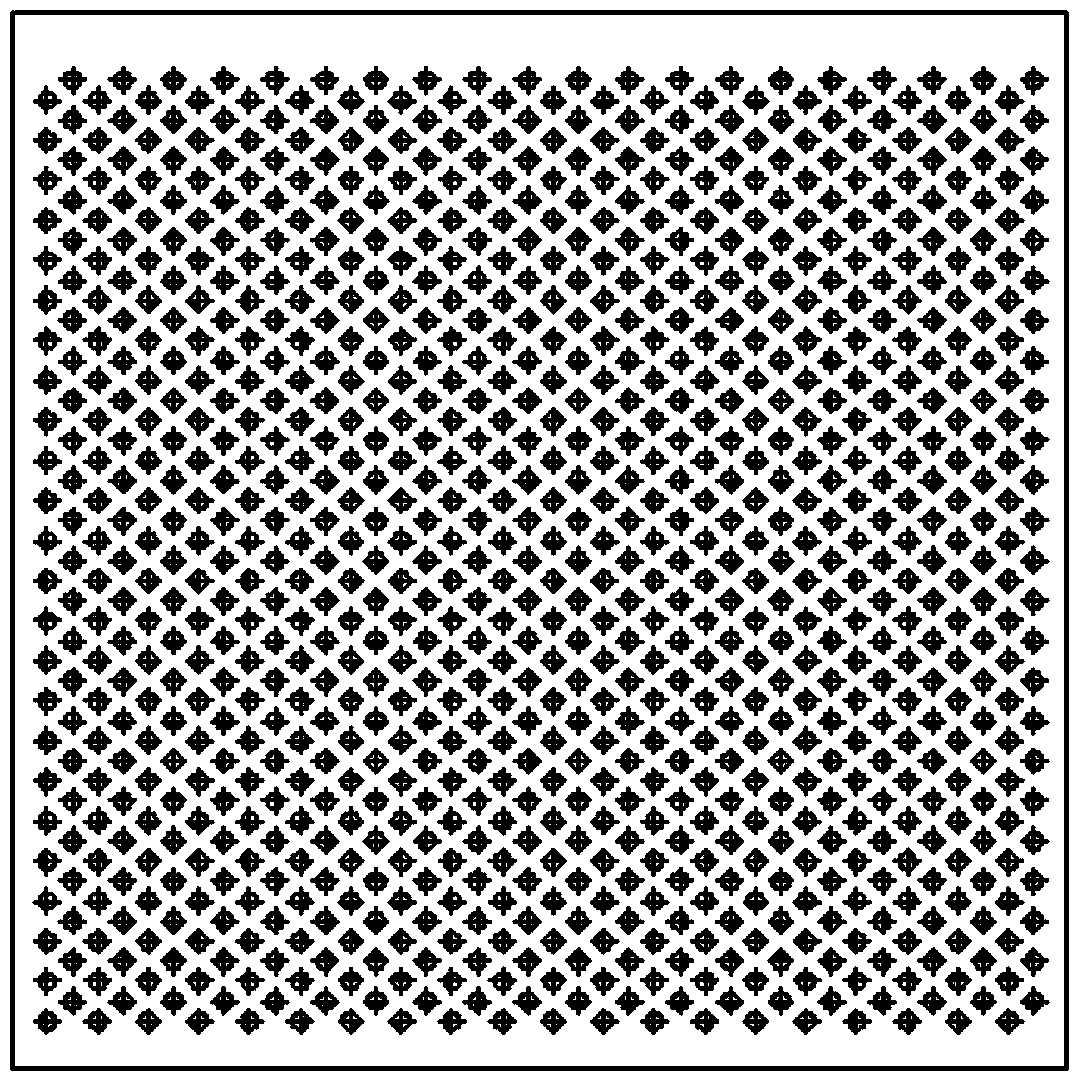

[0030] The diamond-shaped arrangement of heat exchange tube bundles described in the following content (the heat exchange tube bundle is composed of several heat exchange tubes) and the diamond-shaped structure of the shell are the shapes viewed from the section perpendicular to the central axis of the heat exchange tube bundle; the heat exchange tube spacing is Refers to the distance between the central axes of adjacent heat exchange tubes.

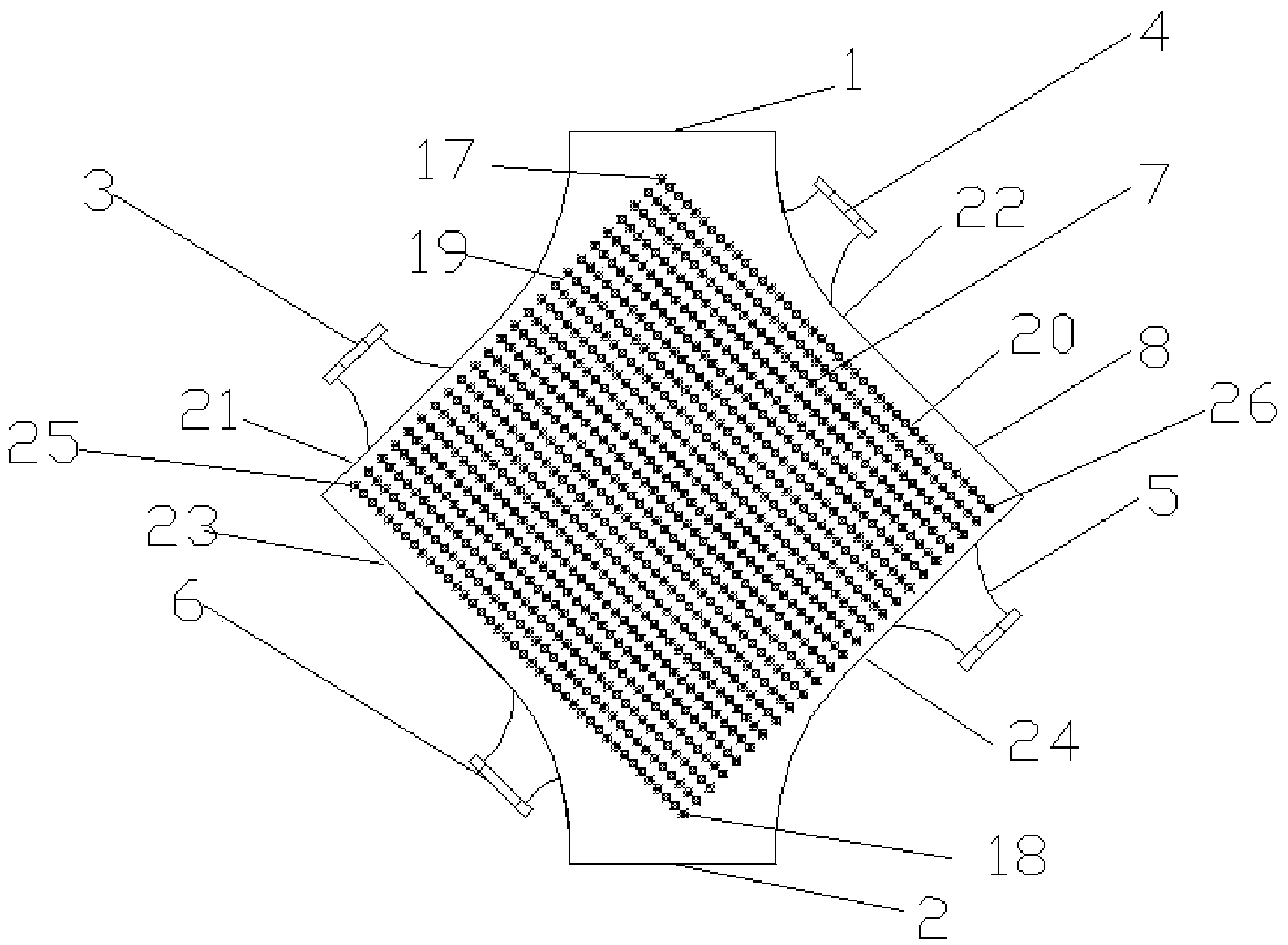

[0031] Such as image 3 As shown, the heat exchanger of the present invention includes a heat exchange tube bundle 7 , an exhaust gas inlet 1 , an exhaust gas outlet 2 and a shell 8 . The heat exchange tube bundle 7 is arranged in the shell 8, and the heat exchange tube bundle is arranged in a rhombus shape, and the first side 19 of the rhombus arrangement of the heat exchange tube bundle is adjacent to the second side 20 of the rhombus arrangement of the heat exchange tube bundle, as Figure 4 As shown, the first side 19 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com