Spout type fluidized bed reactor for synthesis of organic silicon

A fluidized bed reactor and organosilicon technology, applied in organic chemistry, chemical instruments and methods, chemical/physical processes, etc., can solve problems affecting normal production, agglomeration of granular silicon powder, etc., and achieve heat transfer rate Stable, small radial and axial temperature difference, avoiding the effect of gas drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

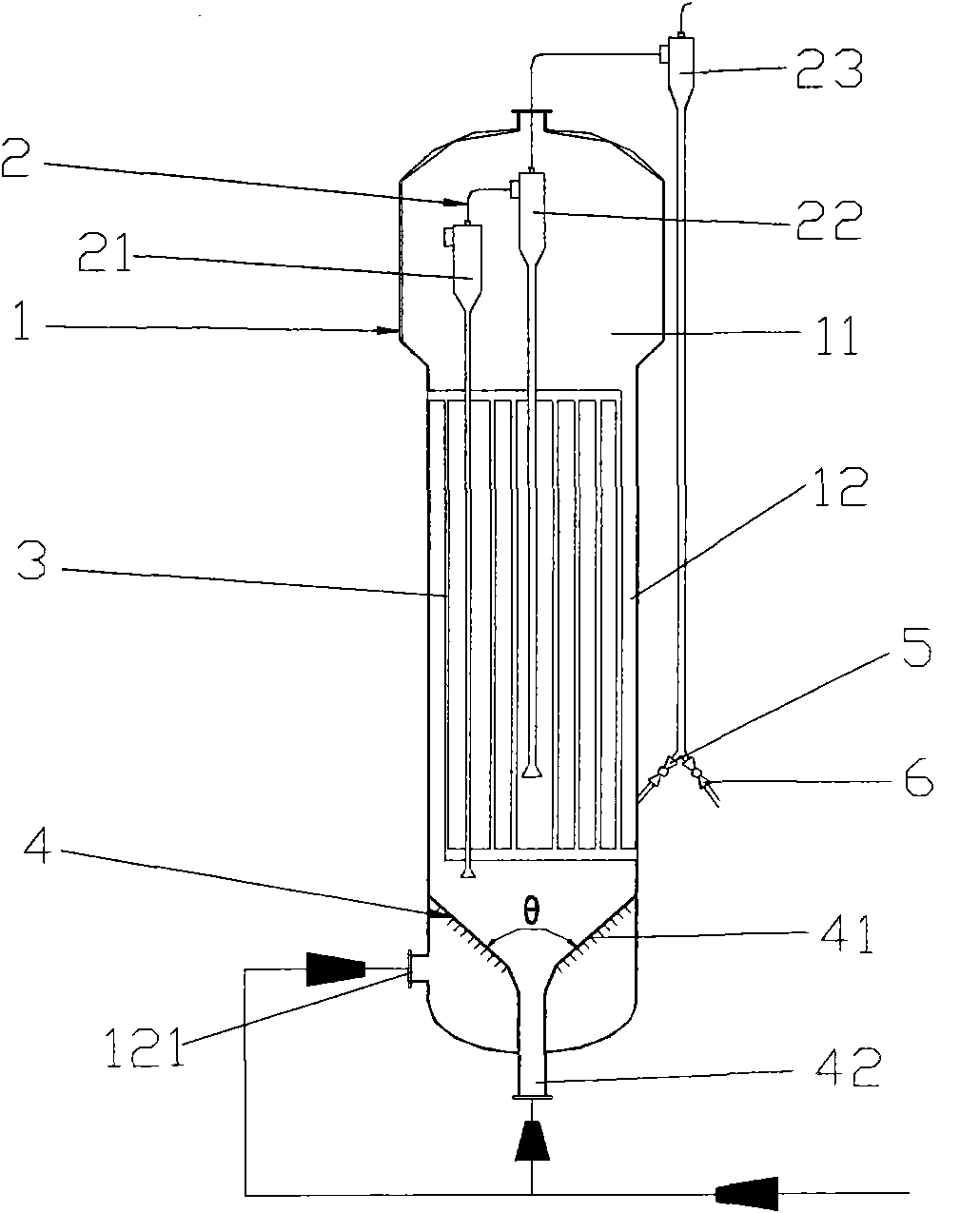

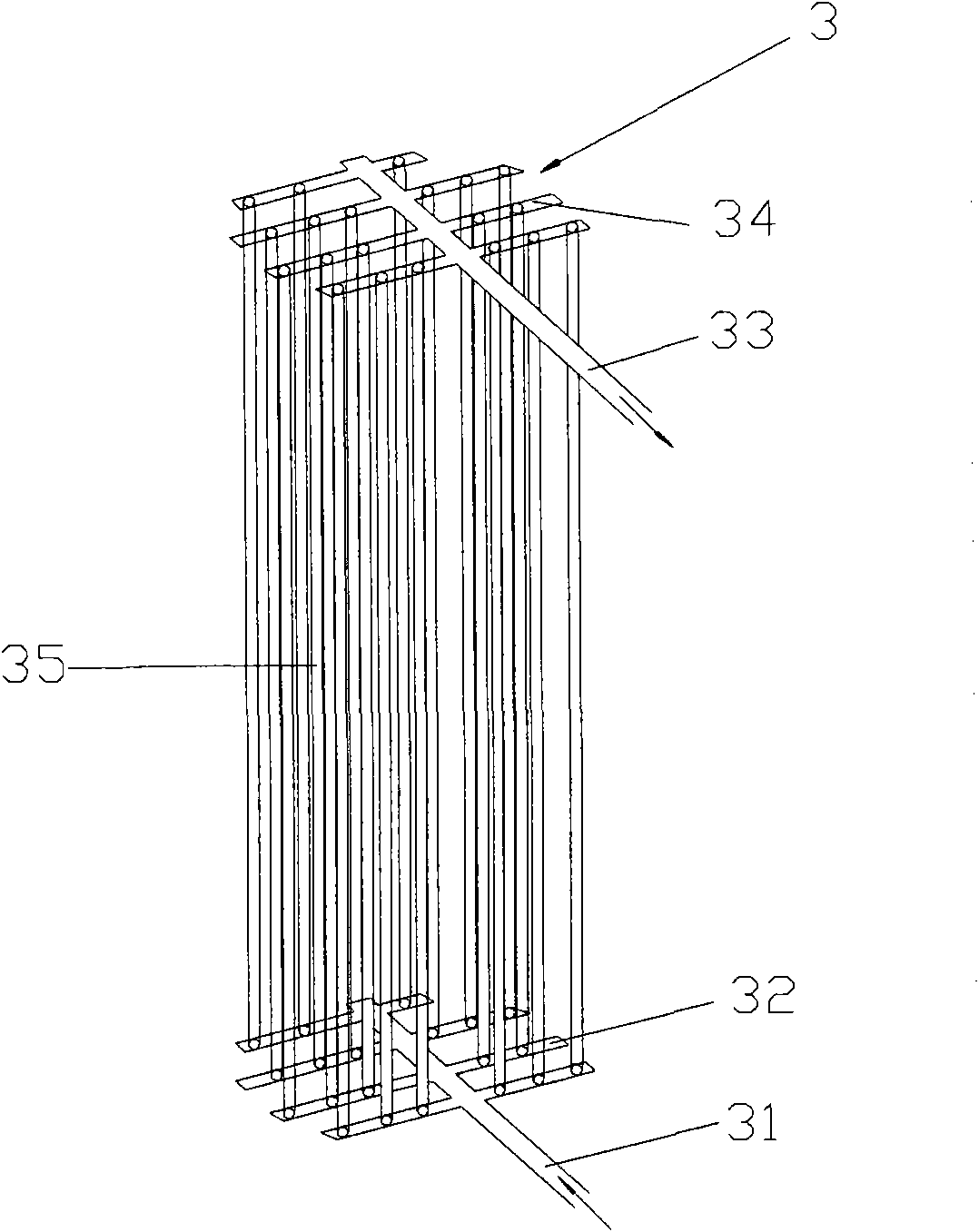

[0032] Such as figure 1 As shown, a schematic structural view of an embodiment of the fluidized bed reactor of the present invention, including a reactor body 1, a cyclone separator assembly 2, a tube-and-tube heat exchanger 3, a tube cone-hole combined distributor 4, and a bed return valve 5 And go to fine powder tank valve 6.

[0033] The reactor body 1 includes a reactor bed 12 and an enlarged body 11 located above the reactor bed. The cyclone separation assembly 2 includes a first-stage inner cyclone component 21 , a second-stage inner cyclone component 22 and an outer cyclone separator 23 connected in sequence. The shell and tube heat exchanger 3 is arranged in the reactor bed 12 . Near the bottom of the reactor bed 12, there is also a pipe-cone-hole combined distributor 4. The bed return valve 5 and the fine powder removal tank valve 6 are located at the lower part of the final material leg of the outer cyclone separator 23, and are used to control the amount of fine ...

Embodiment 2

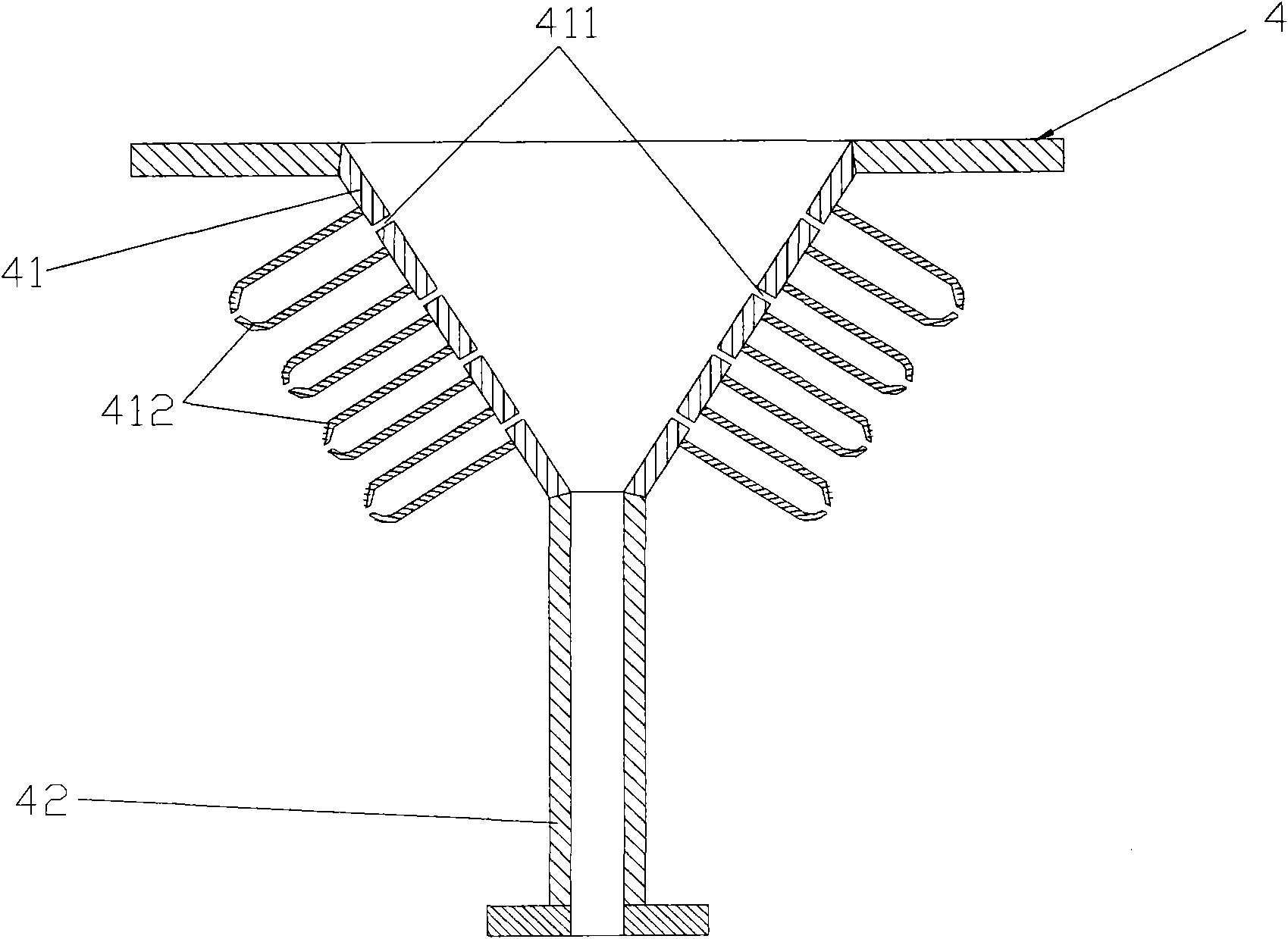

[0039] In a spouted fluidized bed made of plexiglass with a bed diameter F of 300 mm and a bed height H of 4000 mm, the activated carbon particles are fluidized with air, and the average particle diameter dp of the activated carbon particles is 0.355 mm, the maximum The particle size dpmax of the particles is 0.510mm, the cone angle θ of the cone is 90°, the opening diameter on the slope is 3mm, the opening ratio a is 1%, and the diameter dt of the straight pipe is 20mm. When the initial fluidization velocity umf of the particles and the jet fluidization gas volume in the straight pipe are 1.5 to 5.0 times greater than the take-out velocity ut of the carbon particles, when observed with the naked eye, only large and small particles can be seen on the slope of the cone Sliding down smoothly, no carbon particles stay on the distributor, that is, no dead space is generated.

Embodiment 3

[0041] In a hot mold spouted fluidized bed with a bed diameter F of 350 mm and a bed height H of 6000 mm, CH3Cl is used as the fluidized gas to fluidize silicon powder particles at a reaction temperature of 300-310 °C and a reaction pressure of 0.4 MPa. Under the conditions, the synthesis reaction produces organosilicon monomers, the average particle size dp of silicon powder particles is 0.155mm, the particle size dpmax of the largest particle is 0.450mm, the cone angle θ of the cone is 100°, and the hole diameter dor on the slope is 6mm, the opening ratio a is 15%, and the diameter dt of the straight pipe is 25mm. When the fluidization gas volume is greater than the initial fluidization velocity umf of the carbon particles, the sprayed fluidization gas volume in the straight pipe is greater than the carry-out velocity of the silicon particles 1.5 times of ut, the fluidized bed can operate normally. After more than 700 hours of testing, the reaction conversion rate and yield a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com