Cobweb type micro channel heat radiation apparatus

A technology of heat dissipation device and micro flow channel, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of single flow channel direction, tortuous fluid flow path, reduction of heat transfer coefficient, etc., so as to strengthen the convective heat transfer process. , Improve the effect of convection heat transfer coefficient and small friction resistance coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

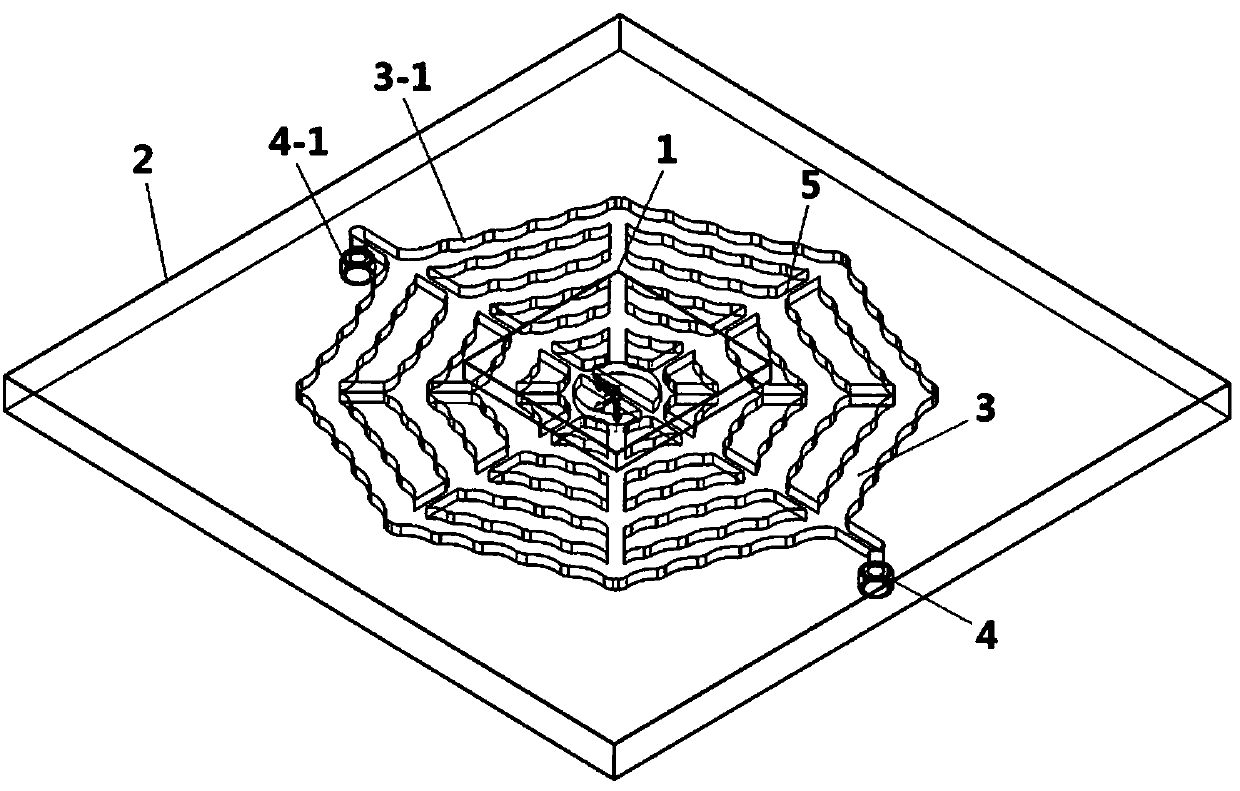

[0028] refer to figure 1 , a cobweb-type micro-channel cooling device, including a substrate 2, the bottom of the substrate 2 is provided with evenly distributed cobweb-like fluid micro-channels 3, the center of the substrate 2 is the center of the fluid micro-channel 3, the The fluid micro-channel 3 radiates outward from the central position, presenting in the shape of circles with different radii. The fluid micro-channel 3 is provided with a "meter"-shaped fluid micro-flow straight channel 5 based on the central position, and the "meter" character The fluid micro-flow straight channel 5 divides the fluid micro-flow channel 3 evenly into 8 equally divided symmetrically distributed sectors, and the two ends of a "meter"-shaped micro-flow straight channel 5 are respectively connected to the bottom of the substrate 2. The cooling medium inlet port 4 and the outlet port 4-1 are connected, the inner wall 3-1 of the fluid microchannel 3 is wavy, and the heat source 1 is placed at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com