Composite stepped wear-resistant lining plate

A wear-resistant liner, stepped technology, applied in grain processing and other directions, can solve the problems of low surface strength of the liner, large maintenance and repair, and rapid wear, etc., to ensure assembly performance, low friction resistance coefficient, and economical cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

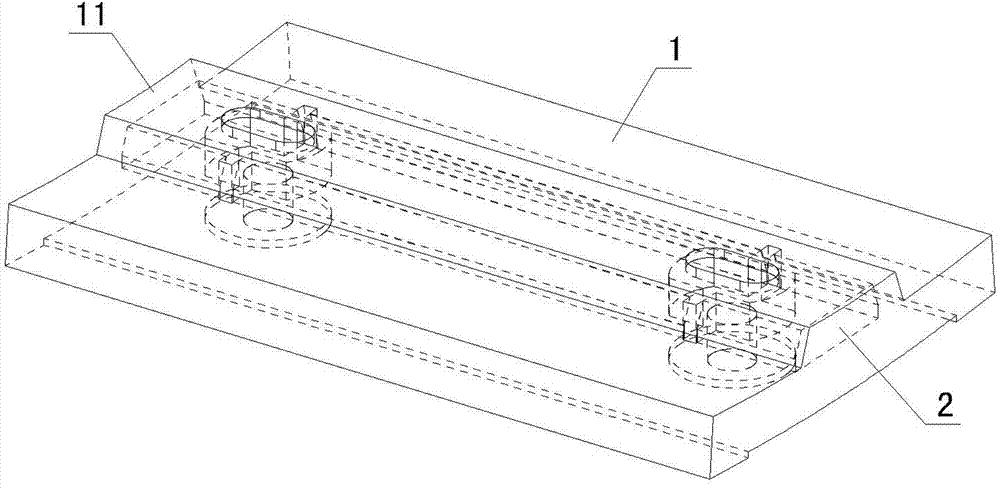

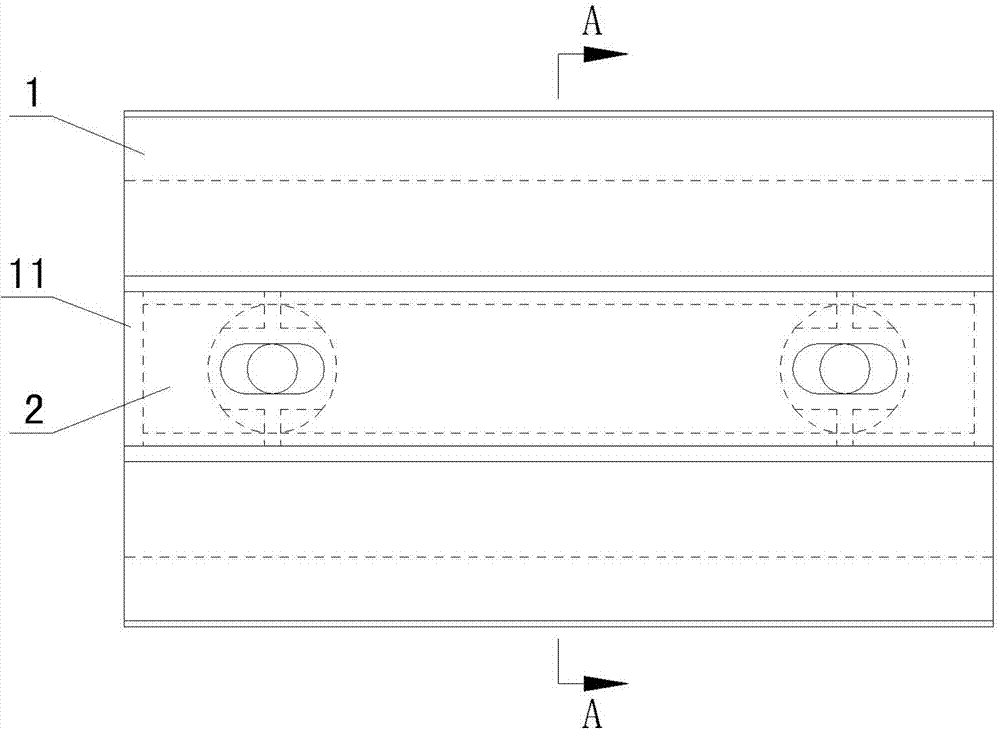

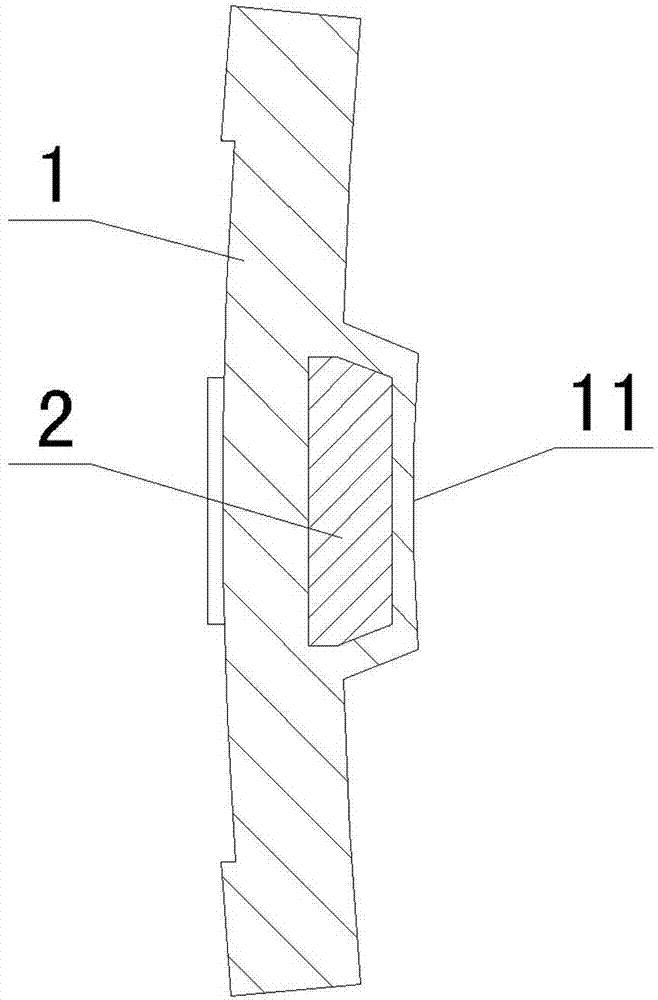

[0017] like Figure 1-Figure 3 As shown, the composite stepped wear-resistant lining of the present invention includes a lining body 1, on which a protrusion 11 forming a stepped structure of the lining body 1 is integrally formed, and the protrusion The protrusion 11 is usually located in the middle of the liner body 1, and the protrusion 11 on the liner body 1 is the main part that bears wear, and the protrusion 11 on the liner body 1 is compounded with a wear-resistant prefabricated body 2. Wherein, the wear-resistant preform 2 is composed of several ceramic particles, and the ceramic particles are tungsten carbide or zirconia toughened alumina ceramic particles. In order to make the manufacturing cost of the present invention low, the ceramic particles are preferably zirconia toughened alumina ceramic particles. Tough alumina ceramic particles. In order to make the interface between the wear-resistant prefabricated body 2 and the liner body 1 described in the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com