Composite and energy-saving river-sea direct ship

A hull and ship technology, applied in the direction of hull, ship propulsion, ship parts, etc., can solve the problems of high bulbous bow construction cost, high bulbous bow design requirements, and ship bottom modification requirements, so as to reduce energy consumption and improve The effect of promoting efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

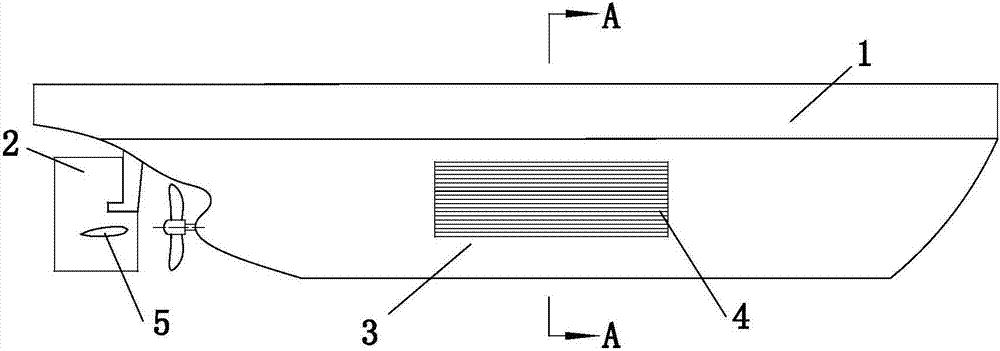

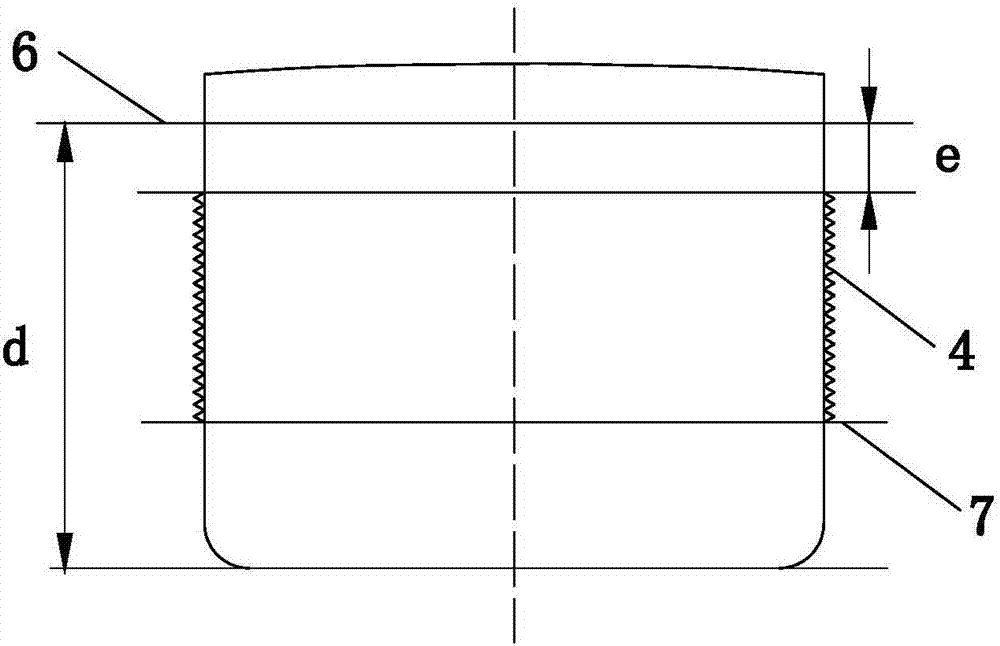

[0029] The composite energy-saving river-sea direct ship shown in the figure includes a hull 1 and a rudder 2 installed at the tail of the hull 1. The parallel center body 3 of the hull 1 is provided with evenly spaced micro-grooves 4 in parallel along the horizontal direction. Both sides of the rudder 2 are symmetrically provided with thrust fins 5 in opposite directions. In this way, by combining the two energy-saving methods of the micro-groove 4 and the thrust fin 5 on the river-sea direct ship, energy consumption is reduced and the energy-saving effect of the ship is improved.

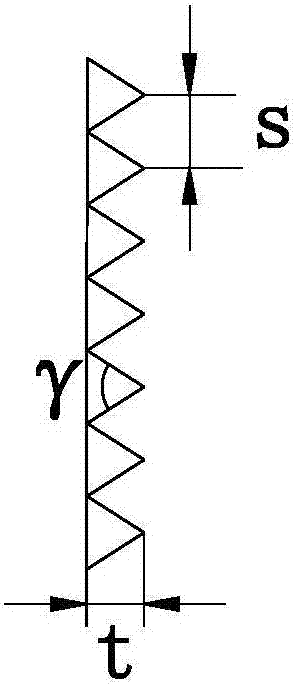

[0030] In the above technical solution, the central axis of the micro-groove 4 coincides with the central axis of the ship parallel body 3, and the ratio of the length of the micro-groove 4 to the ship parallel body 3 is 0.48-0.52:1. In this way, conside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com